Mining grease composition and preparation method thereof

A technology of composition and lubricating grease, which is applied in the field of lubricating grease to achieve the effects of stable product quality, good high-load performance, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

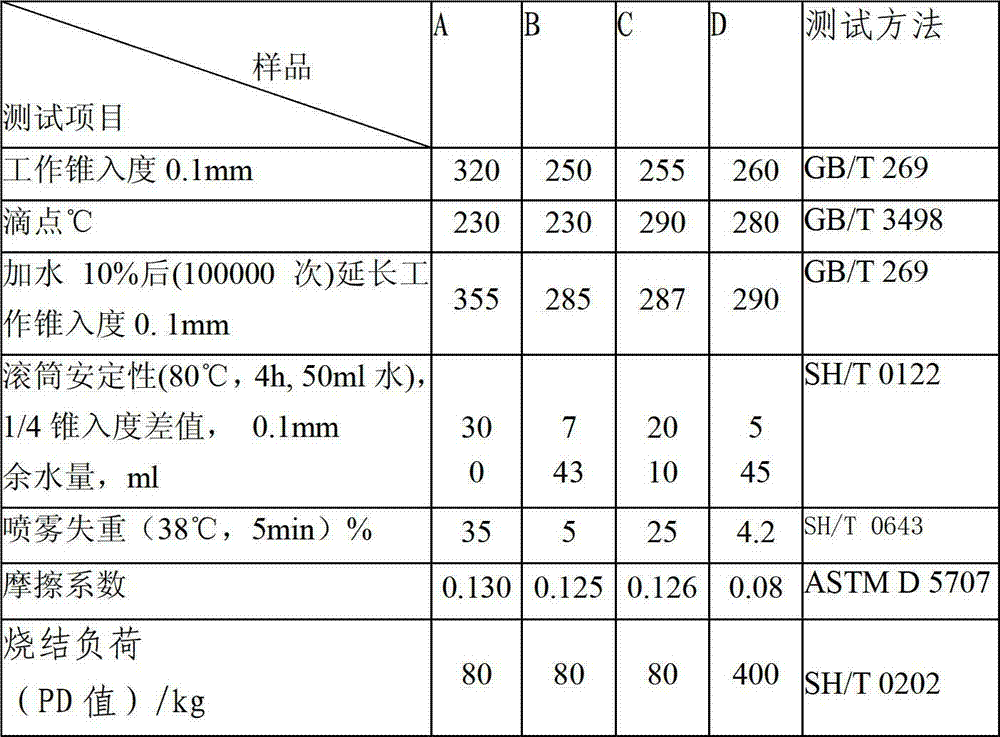

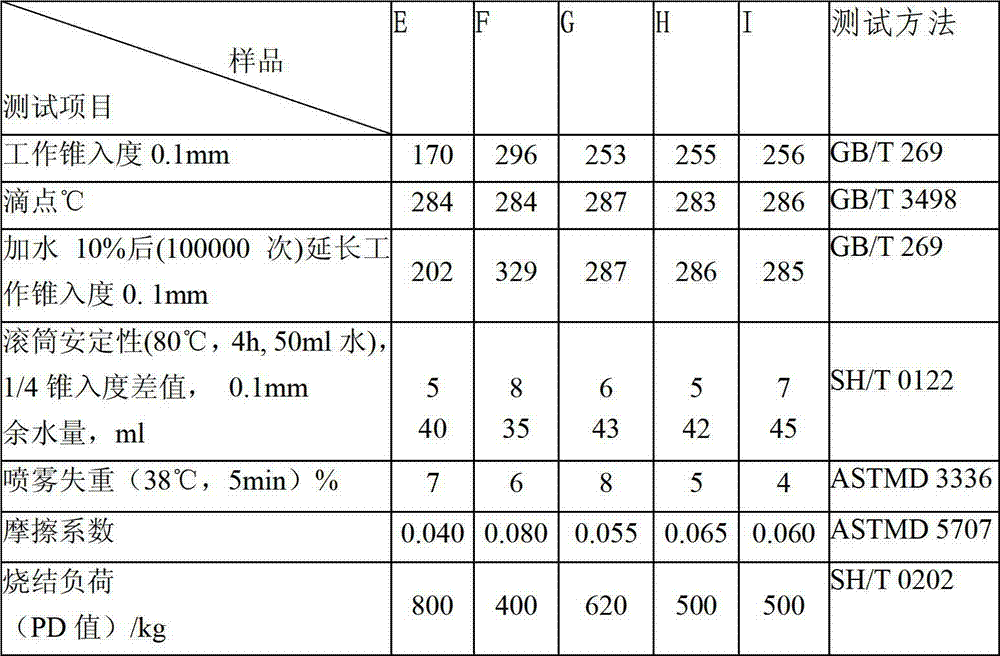

Examples

Embodiment 1

[0041] Base oil: 74.2%;

[0042] Thickener: 18.1%;

[0043] Additives: 7.7%;

[0044] 12-Hydroxystearic acid: 14.1

[0045] Boric acid: 1.3

[0046] Sebacic acid: 2.7

[0047] Ethylene-propylene copolymer: 3.8%;

[0048] Extreme pressure agent: 1.9%;

[0049] Rust inhibitor: 1.0%;

[0050] Antiwear agent: 1.0%.

[0051]Add 14.1% by mass of 12-hydroxystearic acid, 2.7% by mass of sebacic acid and 3.8% by mass of ethylene-propylene copolymer to 74.2% by mass of base oil, mix and heat to 60- 90°C, add lithium hydroxide monohydrate and calcium hydroxide with 1.3% boric acid in mass parts for saponification and compounding for 1.5-2 hours; heat up to 185-190°C in 2 hours, keep this temperature for 1.5 hours; continue to heat up to 220-240 ℃, then naturally lower the temperature to below 120°C, and then add extreme pressure agents (sulfurized olefin cottonseed oil, vanlube829 and vanlube855) with a mass fraction of 1.9%, fatty acid amide with a mass fraction of 1.0%, and tri...

Embodiment 2

[0056] Base oil: 52%;

[0057] Thickener: 25%;

[0058] Additives: 23%;

[0059] 12-Hydroxystearic acid: 20.3%

[0060] Boric acid: 1.3%

[0061] Sebacic acid: 3.4%

[0062] Ethylene-propylene copolymer: 8.0%;

[0063] Extreme pressure agent: 5.0%;

[0064] Rust inhibitor: 5.0%;

[0065] Antiwear agent: 5.0%.

[0066] Add 20.3% by mass of 12-hydroxystearic acid, 3.4% by mass of sebacic acid and 8.0% by mass of ethylene-propylene copolymer to 52% by mass of base oil, mix and heat to 60- 90°C, add lithium hydroxide monohydrate and calcium hydroxide with 1.3% boric acid in mass parts for saponification and compounding for 1.5-2 hours; heat up to 185-190°C in 2 hours, keep this temperature for 1.5 hours; continue to heat up to 220-240 ℃, then naturally lower the temperature to below 120°C, and then add extreme pressure agents (sulfurized olefin cottonseed oil, vanlube829 and vanlube855) with a mass fraction of 5.0%, fatty acid amide with a mass fraction of 5.0%, and triphe...

Embodiment 3

[0068] Base oil: 86%;

[0069] Thickener: 8%;

[0070] Additives: 6%;

[0071] 12-Hydroxystearic acid: 5.9%

[0072] Boric acid: 0.6%

[0073] Sebacic acid: 1.5%

[0074] Ethylene-propylene copolymer: 3.0%;

[0075] Extreme pressure agent: 1.0%;

[0076] Rust inhibitor: 1.0%;

[0077] Antiwear agent: 1.0%.

[0078] Add 5.9% by mass of 12-hydroxystearic acid, 1.5% by mass of sebacic acid and 3.0% by mass of ethylene-propylene copolymer to 86% by mass of base oil, mix and heat to 60- 90°C, add lithium hydroxide monohydrate and calcium hydroxide with 0.6% boric acid in mass parts for saponification and compounding for 1.5-2 hours; heat up to 185-190°C in 2 hours, keep this temperature for 1.5 hours; continue to heat up to 220-240 ℃, then naturally lower the temperature to below 120°C, add extreme pressure agents (sulfurized olefin cottonseed oil, vanlube829 and vanlube855) in parts by mass of 1.0%, succinimide in parts by mass of 1.0% and phosphorothioate in parts by mass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com