Technology for preparing double-amino silane and treating by-product

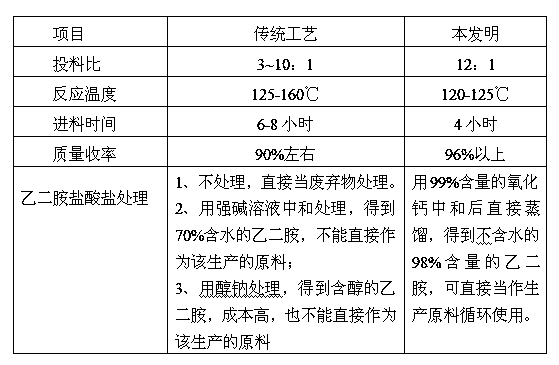

A bisaminosilane and treatment process technology, which is applied in the field of preparation and by-product treatment process, can solve the problems of reduced product yield, low product yield, high cost, etc., to improve product yield, shorten reaction time, The effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Add 12mol (721.2g) of ethylenediamine into the reaction kettle, press 1mol (198.7g) of chloropropyltrimethoxysilane into the metering tank, raise the temperature of ethylenediamine to 120°C under the stirring condition of 100 rpm, and drop Add the chloropropyltrimethoxysilane in the metering tank dropwise to the ethylenediamine in the reaction kettle within 4 hours from the liquid funnel. After the dropwise addition, continue the heat preservation reaction at 120°C for 2 hours, and the reaction will generate N-(β- Aminoethyl)-3-aminopropyltrimethoxysilane and ethylenediamine hydrochloride, then lower the temperature of the kettle to 80°C, and simultaneously turn on the water circulation vacuum pump to recover ethylenediamine 8mol (480.8 grams), after the recovery is completed, the temperature of the kettle is lowered to 40°C, and then the materials in the kettle are introduced into a conical settling kettle under normal pressure and statically stratified for 4 hours. Af...

Embodiment 2

[0024] Add 114.4 grams of ethylenediamine to the reaction kettle, and simultaneously add 480.8 grams of ethylenediamine recovered from the reaction in Example 1 and 126.0 grams of ethylenediamine recovered from ethylenediamine hydrochloride, and 1mol (198.7 grams) of chloropropyl trimethyl Press oxysilane into the metering tank, raise the temperature of ethylenediamine in the reactor to 125°C under stirring at 100 rpm, and then add chloropropyltrimethoxysilane dropwise to the ethylenediamine in the reactor within 4 hours through the dropping funnel. In the diamine, after the dropwise addition, the reaction was continued at 125°C for 2 hours to generate N-(β-aminoethyl)-3-aminopropyltrimethoxysilane and ethylenediamine hydrochloride. When the temperature drops to 80°C, turn on the water circulation vacuum pump to recover 8 mol (480.8 grams) of ethylenediamine under the condition of -0.08MPa. After the recovery is completed, lower the temperature of the kettle to 40°C and introdu...

Embodiment 3

[0027] Add 12mol (721.2 grams) of ethylenediamine into the reaction kettle, press 1mol (240.5 grams) of chloropropyltriethoxysilane into the metering tank, and raise the temperature of the ethylenediamine in the kettle to 122 ℃, within 4 hours through the dropping funnel, add 1 mol (240.5 g) of chloropropyltriethoxysilane dropwise to the reaction tank with the dropping funnel within 4 hours. In the ethylenediamine in the kettle, after the dropwise addition, the reaction was continued at 122°C for 2 hours, and the reaction produced N-(β-aminoethyl)-3-aminopropyltriethoxysilane and ethylenediamine hydrochloride After the reaction is completed, the temperature of the kettle is lowered to 80°C, and at the same time, the water circulation vacuum pump is turned on to recover 8mol (480.8 grams) of ethylenediamine under the condition of -0.08MPa. After the recovery is completed, the temperature of the kettle is lowered to 40°C and the The inner material is introduced into the conical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com