Joint-eliminating and flattening machine used in bamboo processing

A flattening machine and bamboo technology, applied in wood processing equipment, sugarcane machining, mechanical equipment, etc., can solve problems such as fracture, low utilization rate of bamboo and production efficiency, difficulty in unpacking and feeding large-diameter bamboo, and achieve uniformity The effect of good glue penetration and sizing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

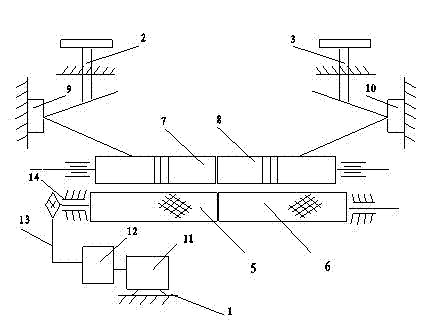

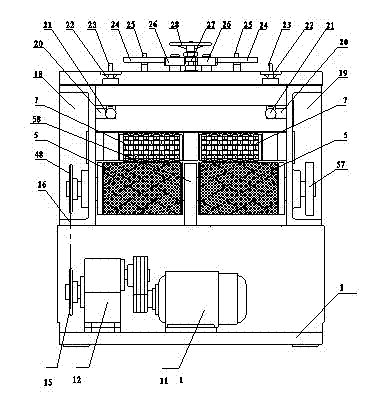

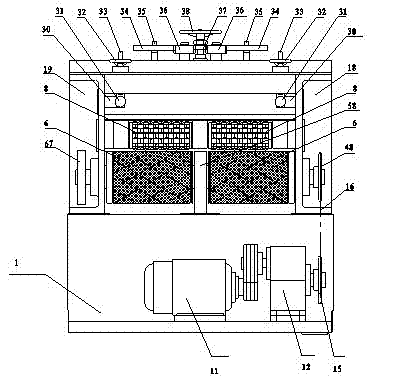

[0032] see Figure 1 to Figure 14 As shown, the composition of the present invention among the figure is as follows: main motor 11, final reduction device 12 are positioned at the bottom of base 1, and the top of base 1 is provided with left box body 18, right box body 19, friction roller intermediate support wallboard 58, box The body connecting rod 17 is fixed on the left box body 18, the right box body 19, and the middle supporting wallboard 58 of the friction roller. 18. The top of the right box body 19. The left box body 18 and the right box body 19 are provided with the first friction roller shafting 5 actively rotating and feeding, the first jointer shafting support frame 9 and the shafting support frame 9 installed on the first jointer shafting support frame. The first picker shafting 7 for passive rotation. Also on the lef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com