Processing method and processing device of shaft hole of guide vane of inner and outer water distribution ring of water turbine

A hole processing method and technology of the processing method, which are applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problems that the inner and outer ring holes cannot meet the requirements of coaxiality, inaccurate positioning, and low processing efficiency. Achieving good economic benefits, ensuring high precision, precision and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

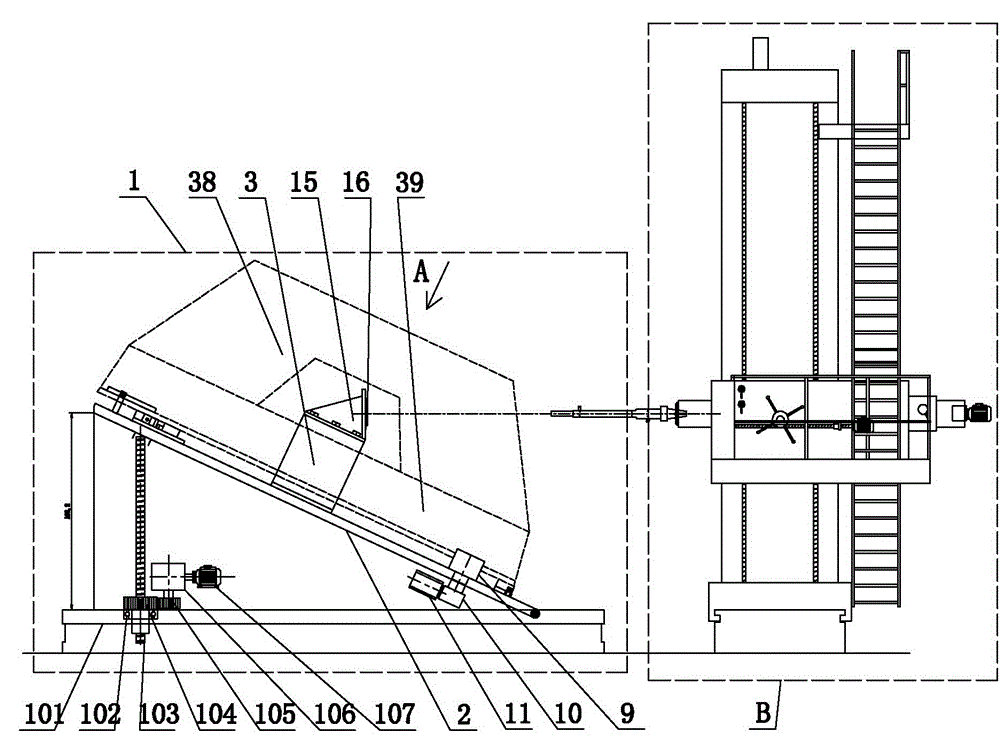

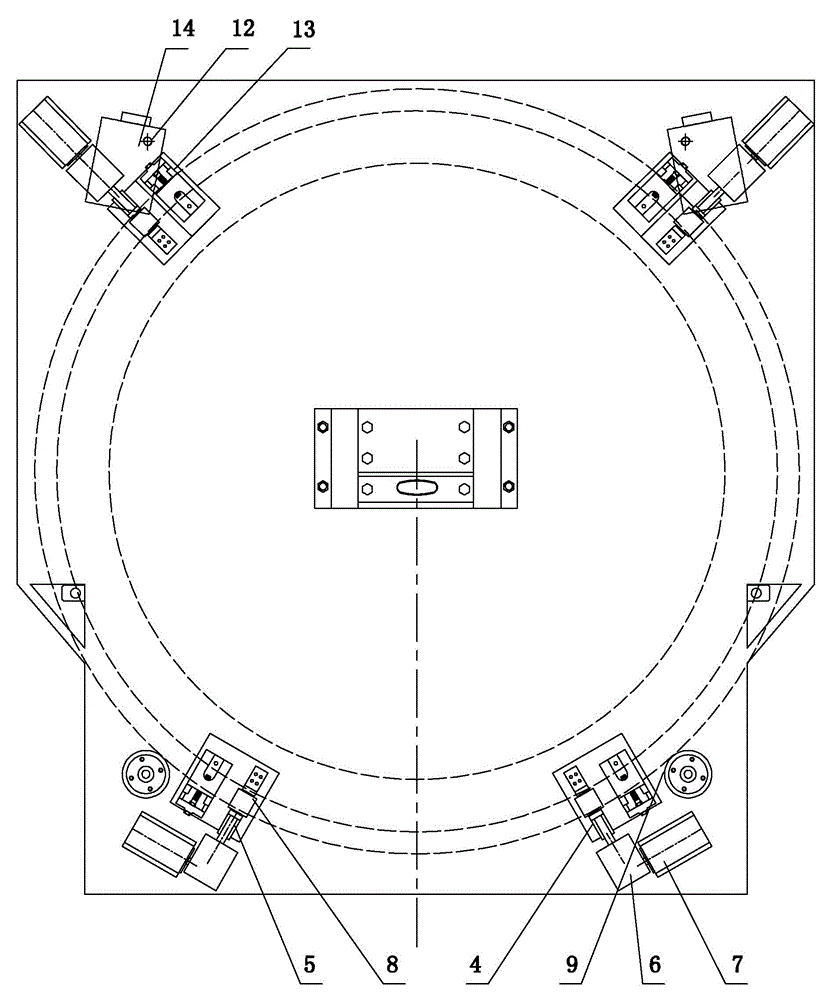

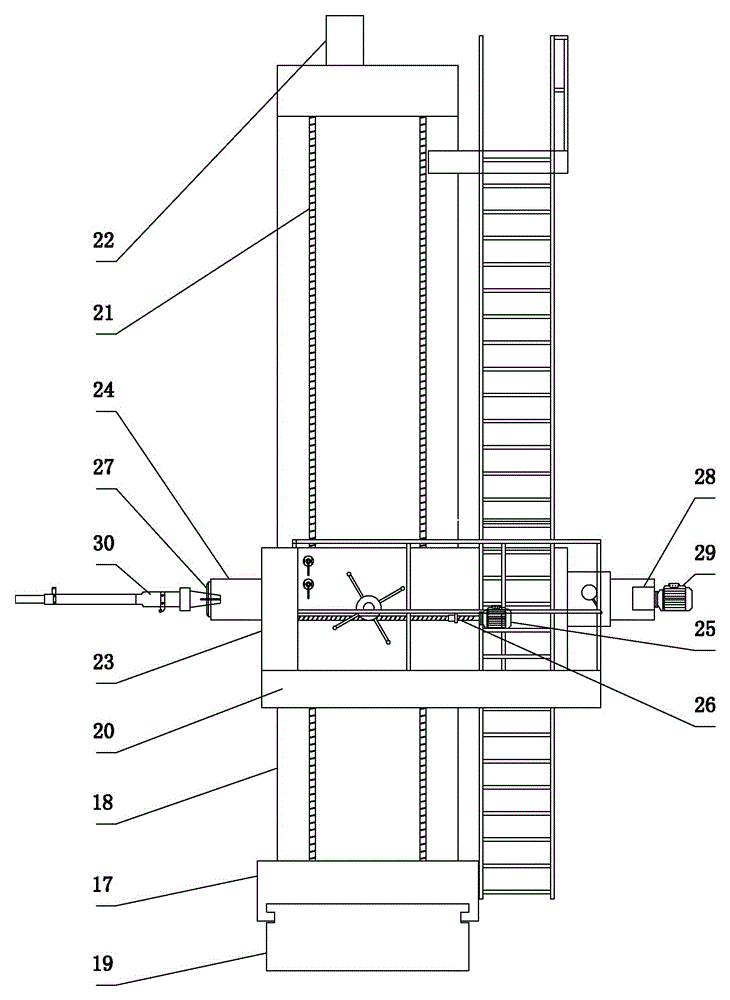

[0019] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0020] figure 1 It is a structural schematic diagram of the present invention, figure 2 It is a schematic diagram of the turntable A direction, image 3 yes figure 1 A schematic diagram of part B is shown, Figure 4 is a schematic diagram of a double-ended boring bar. The processing steps of the machining method for the guide vane shaft hole of the inner and outer water distribution ring of the turbine are: A. Scribing: Based on the processing surface 381 of the outer water distribution ring, draw the guide vane shaft hole of the outer water distribution ring 16-Ф224, 25° angle correction line, and the bottom surface is vertical Calibration line; based on the processing surface 382 of the inner water distribution ring, draw the shaft hole 16-Ф140 of the guide vane of the inner water distribution ring an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com