Quick die replacement mechanism for low pressure casting machine

A low-pressure casting machine, fast technology, applied in the field of rapid mold changing mechanism, can solve problems such as low efficiency, and achieve the effect of improving utilization rate, saving time and manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

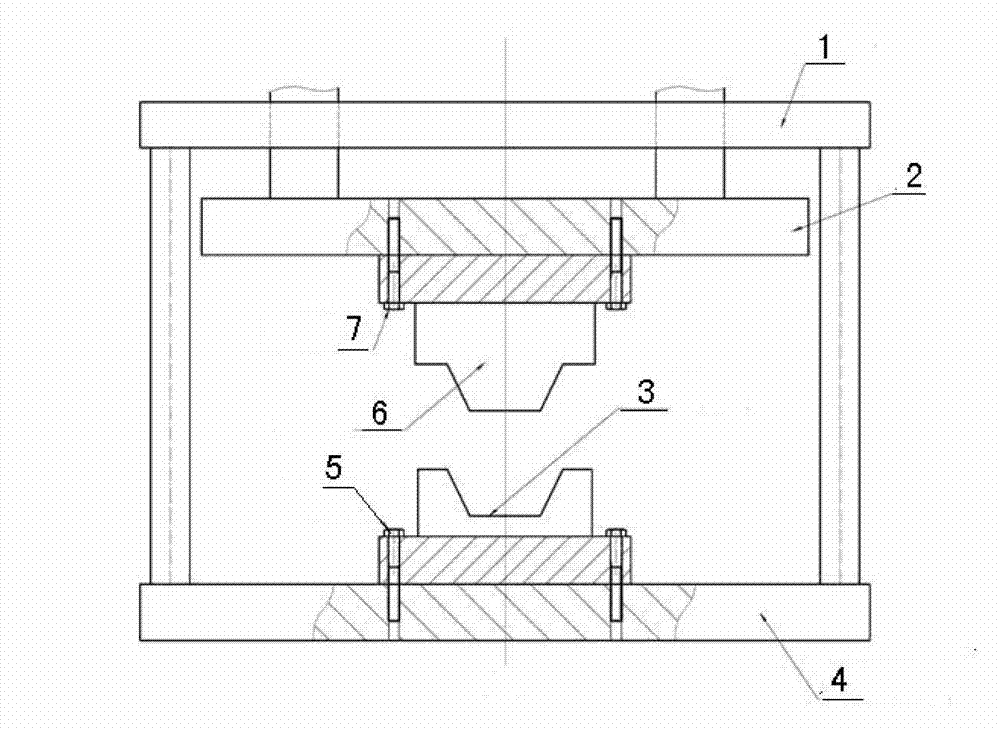

[0009] by figure 1 Known, it is the mold change structure of the prior art. The mold changing mechanism of the commonly used low-pressure casting machine is composed of 1 frame, 2 upper mold fixing plates, 3 lower molds, 4 lower mold fixing plates, 5 lower clamping bolts, 6 upper molds, and 7 upper clamping bolts. The method is to directly fix the mold on the fixing plate 2 by bolts, and manually use tools to tighten the bolts one by one to replace the mold.

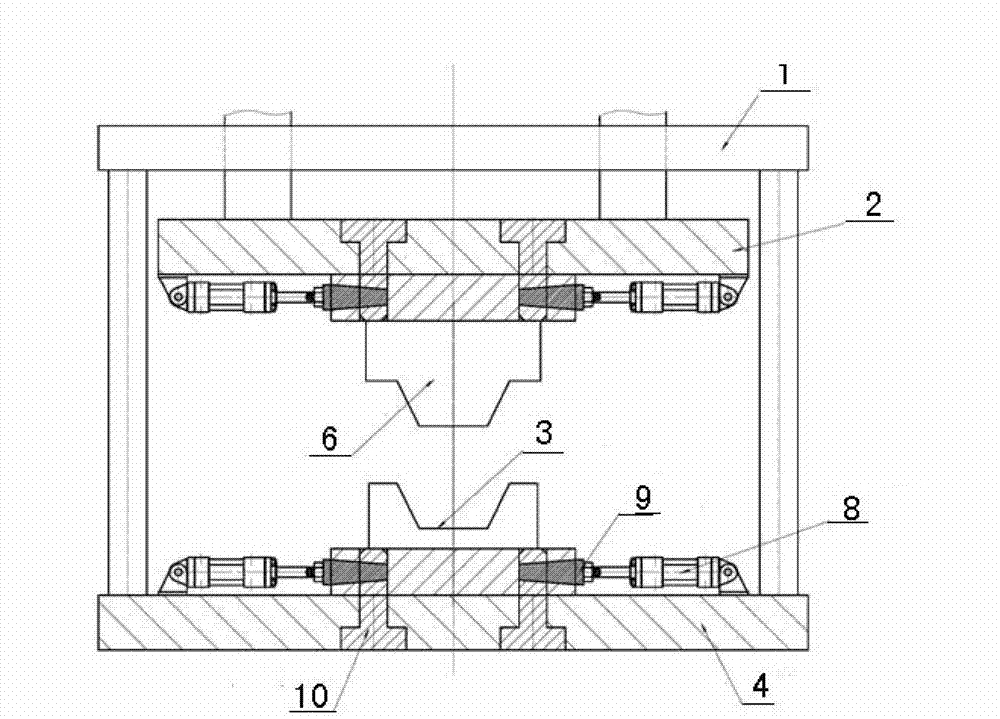

[0010] by figure 2 Known is a schematic diagram of the structure of the present invention. It is composed of 1 frame, 2 upper mold fixing plates, 3 lower molds, 4 lower mold fixing plates, 6 upper molds, 8 hydraulic cylinders, 9 lock tongues, and 10 locks, which are fixed on the original upper mold fixing plate 2 and lower mold Four sets of locking mechanisms are added to the plate 4, and the locking mechanism is composed of a hydraulic cylinder 8, a lock tongue 9 and a lock buckle 10. When the hydraulic cylinder 8 pull...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com