Nutritional vermicelli and making method thereof

A technology for dried noodles and nutrition, applied in the field of nutritious dried noodles and its preparation, can solve the problems of poor taste, single nutrient composition of dried noodles, unable to meet the requirements of dietary nutrition, etc., and achieves the effects of rich nutrition, rich nutrients, and prevention of cardiovascular diseases.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

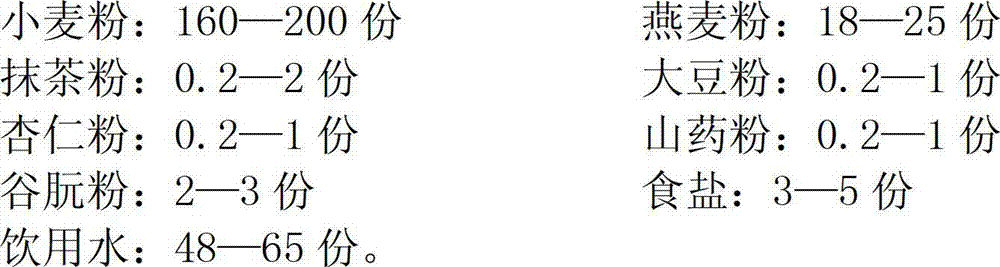

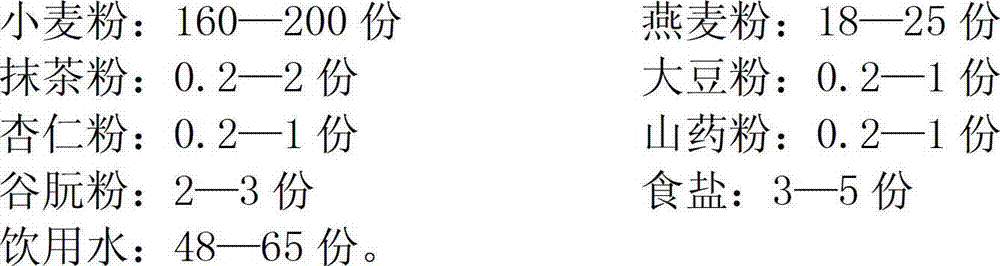

Embodiment 1

[0020] A kind of nutritional dried noodles, its preparation method is:

[0021] (1) Put 160 parts of wheat flour, 18 parts of oat flour, 2 parts of matcha powder, 0.5 parts of soybean powder, 1 part of almond powder, 1 part of yam powder, 2 parts of gluten powder, and 3 parts of table salt into the dough mixer for stirring , and then gradually add 48 parts of drinking water at 20°C to the dough mixer, the speed of the dough mixer is 100 rpm, and the dough mixing time is 10 minutes. After stirring evenly, the dough is made;

[0022] (2) Put the dough prepared above into a curing machine, the speed of the curing machine is 8 rpm, the time is 20 minutes, and the curing temperature is 20°C;

[0023] (3) compressing the above-mentioned matured dough through a tablet press, the thickness of the dough sheet after the tablet molding is 1.2mm; the dough sheet of the tablet molding is cut into strips to make semi-finished noodles;

[0024] (4) Put the semi-finished noodles after cuttin...

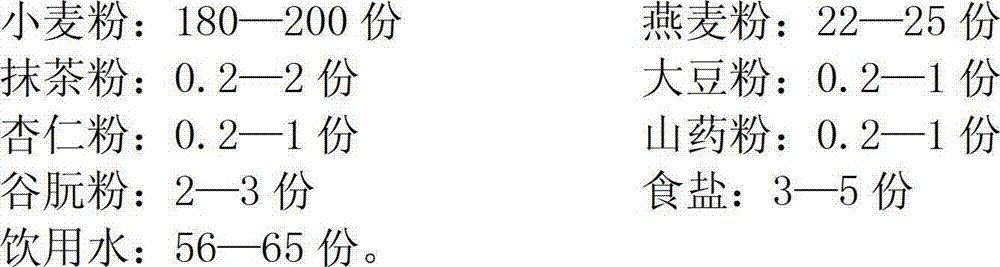

Embodiment 2

[0027] A kind of nutritional dried noodles, its preparation method is:

[0028] (1) Put 180 parts of wheat flour, 22 parts of oat flour, 0.5 parts of matcha powder, 0.2 parts of soybean powder, 0.2 parts of almond powder, 0.2 parts of yam powder, 2 parts of gluten powder, and 4 parts of table salt into the dough mixer for stirring , and then gradually add 56 parts of drinking water at 20°C to the dough mixer, the speed of the dough mixer is 85 rpm, and the dough mixing time is 13 minutes. After stirring evenly, the dough is made;

[0029] (2) Put the dough prepared above into a curing machine, the speed of the curing machine is 10 rpm, the time is 17 minutes, and the curing temperature is 20°C;

[0030] (3) compressing the above-mentioned cooked dough through a tablet press, the thickness of the dough sheet after the tablet molding is 1.0mm; the dough sheet of the tablet molding is cut into strips to make semi-finished noodles;

[0031] (4) Put the semi-finished noodles after...

Embodiment 3

[0034] A kind of nutritional dried noodles, its preparation method is:

[0035] (1) Put 200 parts of wheat flour, 25 parts of oat flour, 1 part of matcha powder, 1 part of soybean powder, 0.5 part of almond powder, 0.6 part of yam powder, 3 parts of gluten powder, and 5 parts of salt into the dough mixer for stirring , and then gradually add 65 parts of drinking water at 25°C to the dough mixer, the speed of the dough mixer is 70 rpm, and the dough mixing time is 15 minutes. After stirring evenly, the dough is made;

[0036] (2) Put the dough prepared above into a curing machine, the speed of the curing machine is 10 rpm, the time is 15 minutes, and the curing temperature is 25°C;

[0037] (3) compressing the above-mentioned cooked dough through a tablet press, the thickness of the dough sheet after the tablet molding is 1.0mm; the dough sheet of the tablet molding is cut into strips to make semi-finished noodles;

[0038] (4) Put the semi-finished noodles after cutting into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com