Axial flow blower

An axial flow fan and airflow technology, which is applied in axial flow pumps, mechanical equipment, machines/engines, etc., can solve the problems of turbulent airflow, increased noise, and increased pressure difference, so as to suppress turbulent flow and realize noise reduction , low noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Hereinafter, embodiments of the present invention will be described based on the drawings.

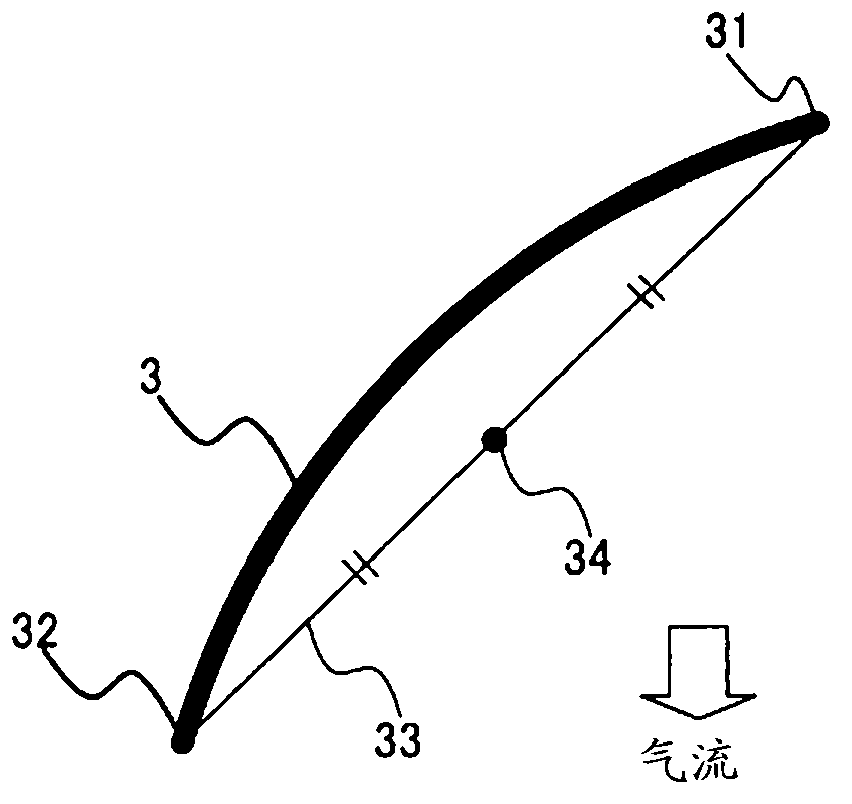

[0019] figure 1 It is a perspective view which shows the structure of the axial flow fan of this embodiment. figure 2 It is a front view showing the structure of the axial flow fan of this embodiment. image 3 yes means figure 2 Plane development of the I-I section of . Figure 4 It is a projected view showing the chord centerline of the axial flow fan according to the present embodiment and a blade cross section taken by a curved surface including the chord centerline and parallel to the rotation axis, projected on a plane including the rotation axis. Figure 5 It is an explanatory drawing for demonstrating the flow field of the axial flow fan of this embodiment. Image 6 It is a graph showing the relationship between Ro / (Rt-Rb) and the standard noise reduction amount in the axial flow fan according to the present embodiment. Figure 7 It is a graph showing the relations...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com