Automatic production management system and automatic production management method for automobile electrophoretic painting

A production management system, electrophoretic coating technology, applied in the direction of electrical program control, comprehensive factory control, comprehensive factory control, etc., can solve the problems of paper consumption, waste of time, manpower and material resources, high probability of human error, etc., to achieve the goal of finding Convenience and small storage space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

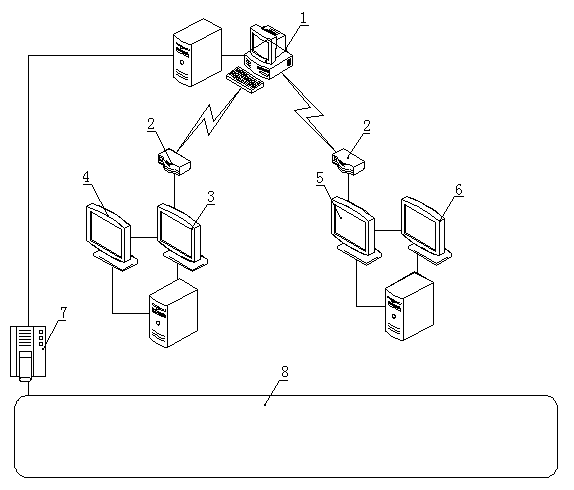

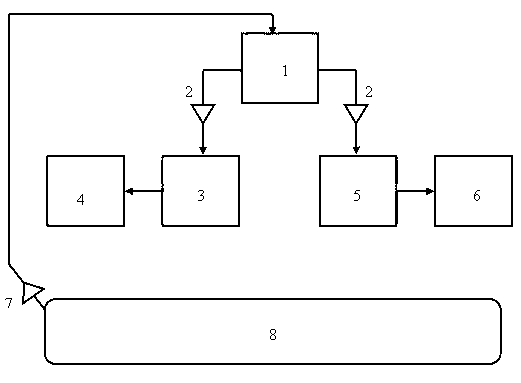

[0013] The present invention will be further described in conjunction with the accompanying drawings.

[0014] as attached figure 1 , attached figure 2 As shown, the present invention discloses an automated production management system and method for electrophoretic coating of automobiles, which includes:

[0015] Production management control center 1, used to input data information and receive production feedback information;

[0016] Information input and output controllers, including an information output controller 2 and a production information feedback controller 7, the information output controller 2 is used to output product scheduling information, and the information feedback controller 7 is used to feed back the actual production situation of the production line;

[0017] Data information display unit, used to display production scheduling information and work instructions, including on-line production scheduling information display 3, on-line operation instructi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com