Method for weighing electric excavator

An electric excavator and weighing technology, applied to mechanically driven excavators/dredgers, weighing, instruments, etc., can solve problems such as unsuitable wire ropes and material weight errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

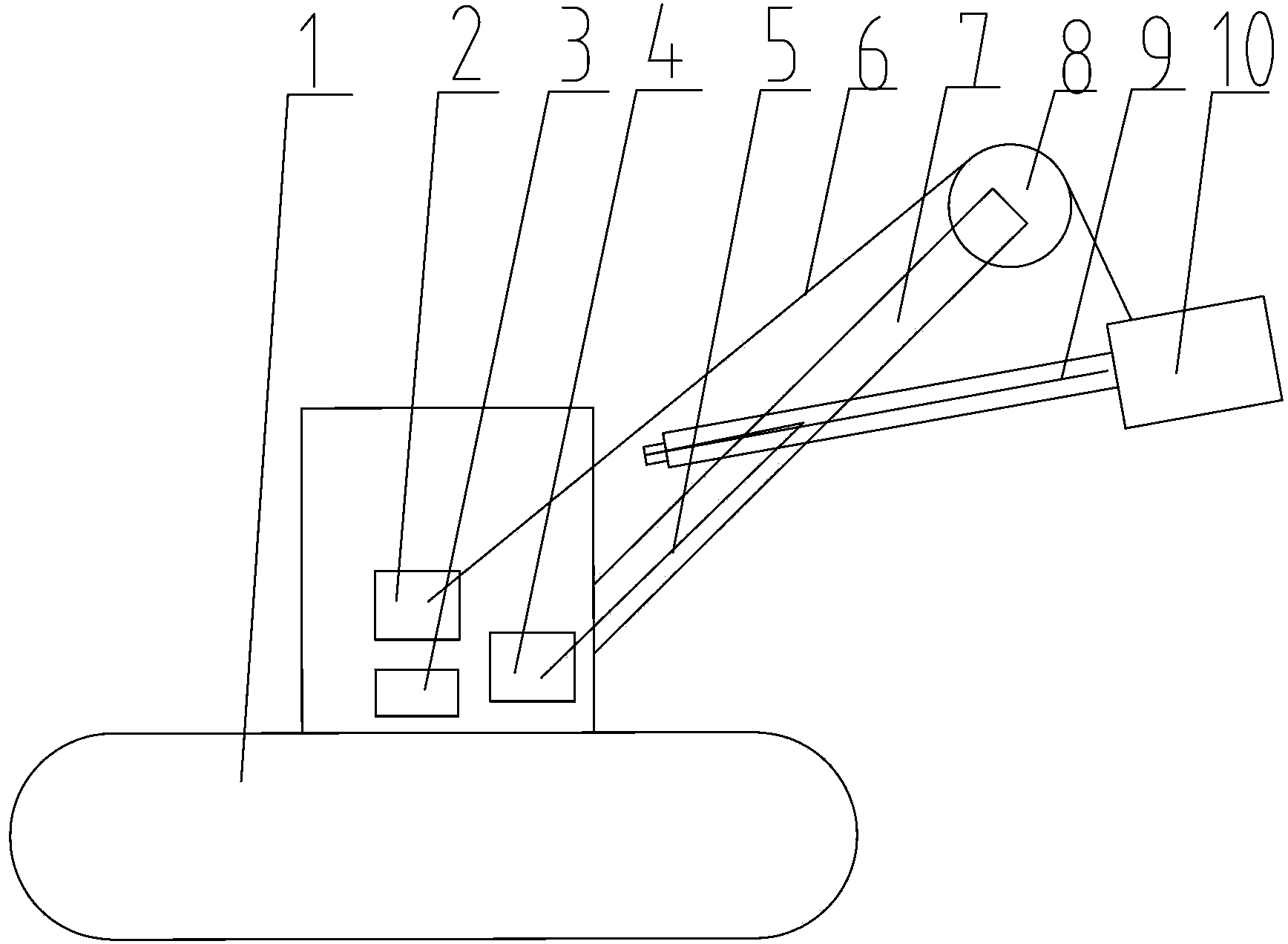

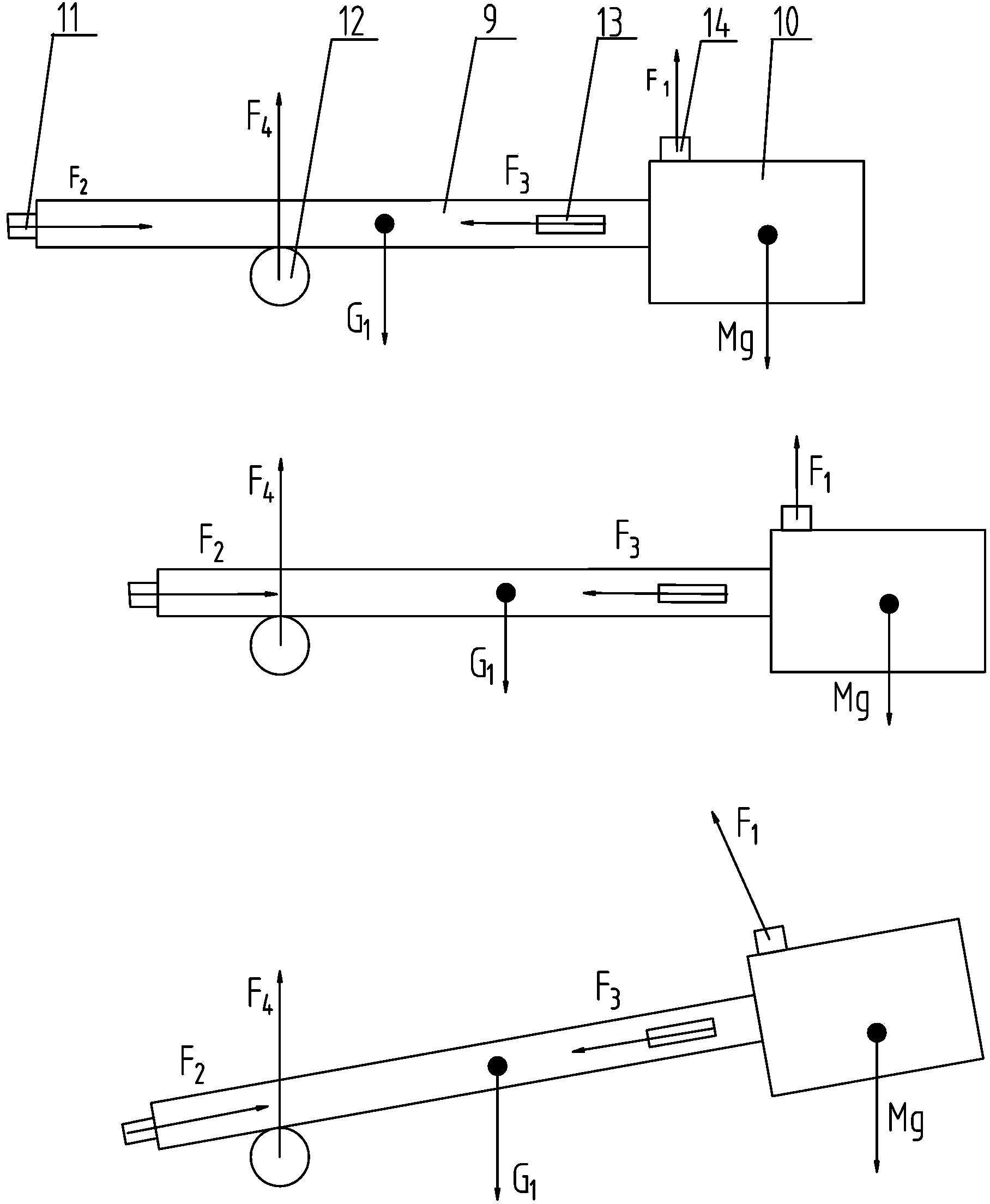

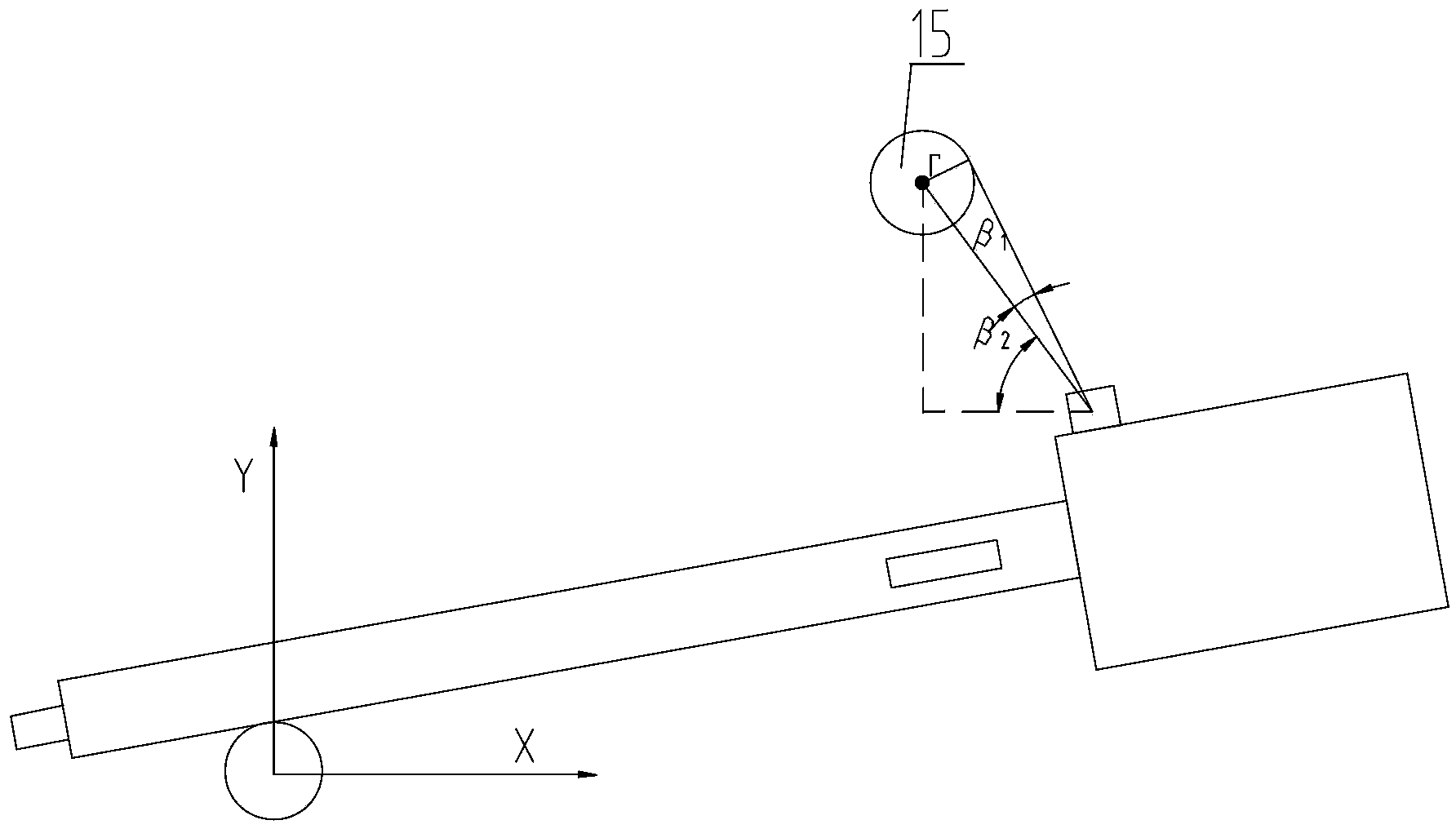

[0060] Such as figure 1 As shown, an electric excavator generally consists of a traveling mechanism 1, a lifting mechanism 2, a slewing mechanism 3, a pushing mechanism 4 and electrical parts. The walking mechanism 1 brings the electric excavator to the excavation destination; the pushing mechanism 4 pulls the pushing wire rope 5 to push the bucket 10 fixedly installed on the shovel rod 9 to shovel into the ore body; the lifting mechanism 2 pulls the lifting wire rope 6 and lifts it up for fixed installation The bucket 10 on the shovel bar 9 makes the ore fill the bucket 10 and stay at a height higher than the body of the electric wheel dump truck; the slewing mechanism 3 rotates the bucket 10 filled with ore from the side of the ore body to the electric wheel On the side of the dump truck, then the bucket 10 is opened, and the ore is poured into the dump truck, then the electric excavator turns back to the original position, and the hoisting mechanism puts down the bucket, re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com