Rack for high-speed data transmission system between rotating body and fixed body

A high-speed data transmission and fixed body technology, applied in the direction of machine/support, supporting machine, mechanical equipment, etc., can solve the problems that cannot meet the requirements of the data transmission system, and achieve simple structure, short batch production cycle and reliable operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with specific drawings and embodiments.

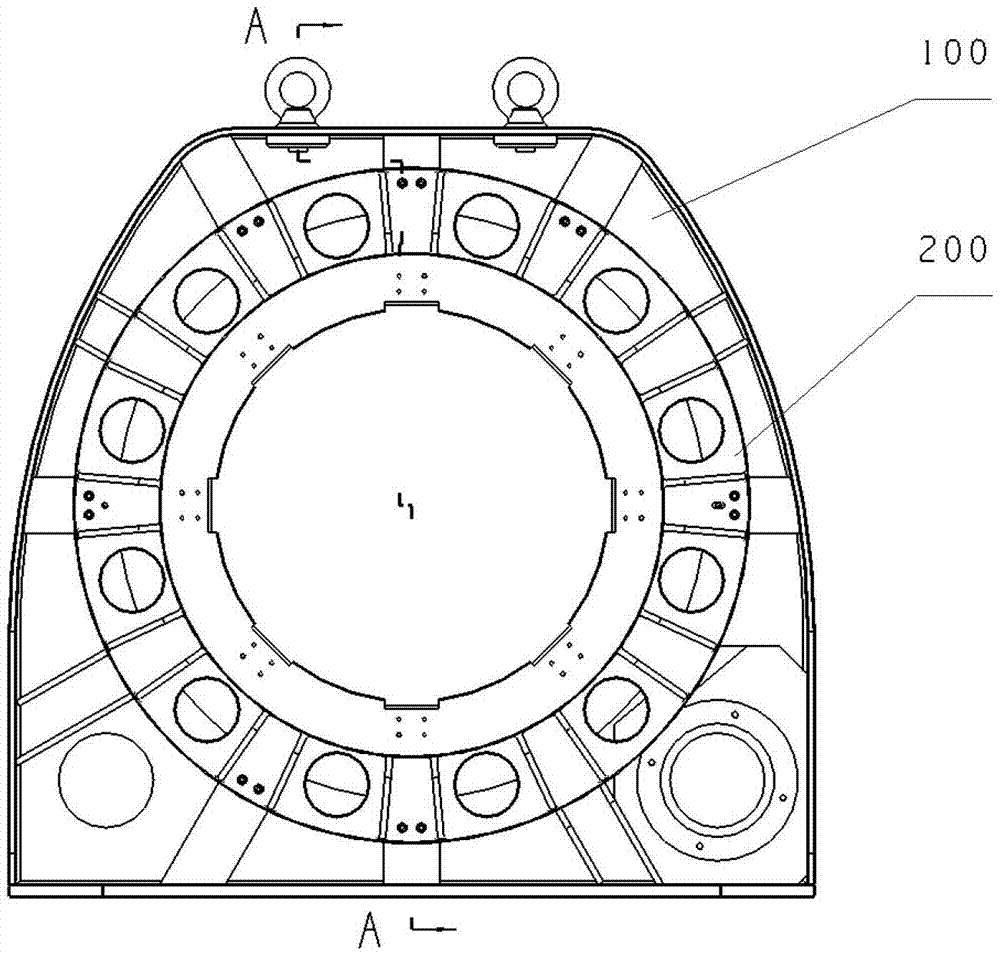

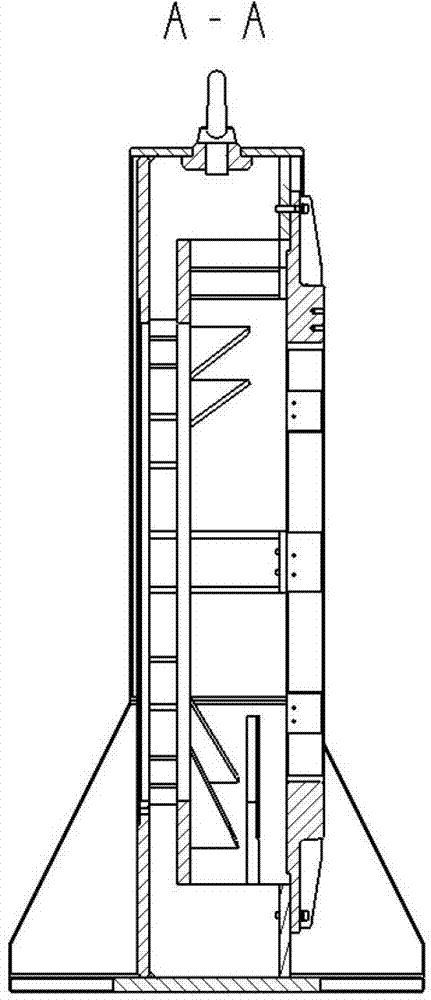

[0017] Such as figure 1 , 2 As shown, the rack in this embodiment is mainly composed of the rack assembly 100 and the receiving device installation part 200 .

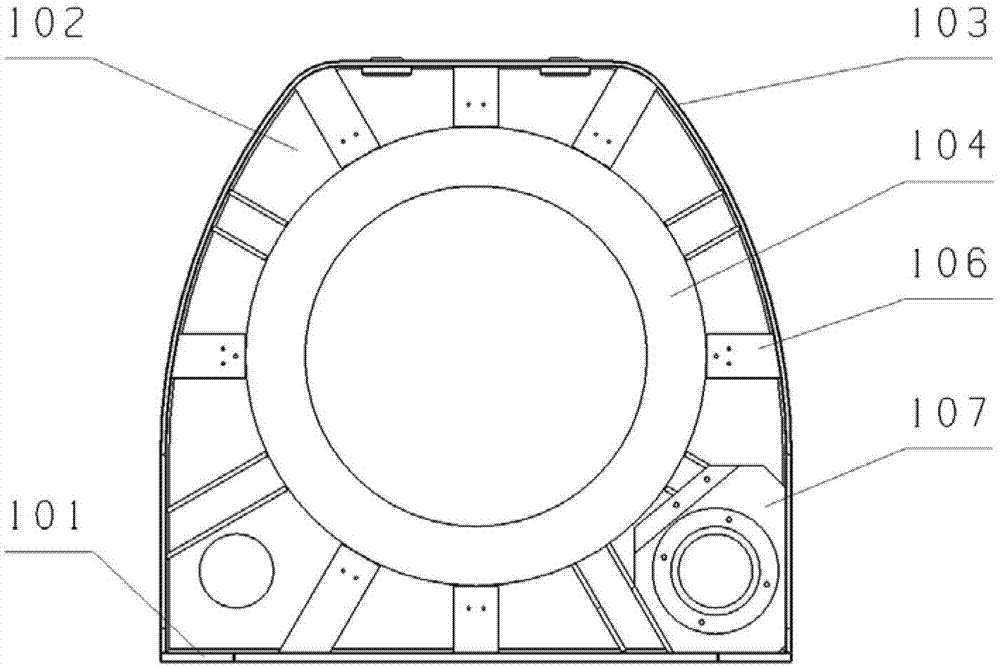

[0018] Such as Figure 3-6 As shown, the rack assembly 100 in this embodiment includes: a base plate 101, a vertical plate 102, an inverted U-shaped frame 103, an annular plate 104, a trapezoidal plate 105, several receiving device mounting plates 106, a motor mounting plate 107, several Ribs 108 etc. are all fixedly connected between them. The bottom plate 101 is in the shape of an I-shape, and is laid flat on the bottom of the entire frame welding assembly 100; the center of the vertical plate 102 has a through hole, and the bottom of the vertical plate 102 is vertically fixed on the bottom plate 101, and the upper part of the vertical plate 102 is the same shape as the inverted U-shaped frame 103 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap