Pressure-limit air-leakage auxiliary braking valve device with air vent of piston tappet sleeve

A technology of auxiliary brake and valve device, which is applied in the direction of engine control, machine/engine, mechanical equipment, etc., which can solve the problem of the inability of the inner cavity of the pressure regulating device to dissipate heat, the delay of the braking effect of the auxiliary brake valve, and the inability to effectively control the exhaust Problems such as back pressure can be effectively controlled, the exhaust back pressure can be improved, and the resistance is small.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Several preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention is not limited to these embodiments. The present invention covers any alternatives, modifications, equivalent methods and schemes made on the spirit and scope of the present invention. In order to provide the public with a thorough understanding of the present invention, specific details are set forth in the following preferred embodiments of the present invention, but those skilled in the art can fully understand the present invention without the description of these details. In addition, well-known methods, procedures, processes, components, etc. have not been described in detail in order to avoid unnecessary confusion to the essence of the present invention.

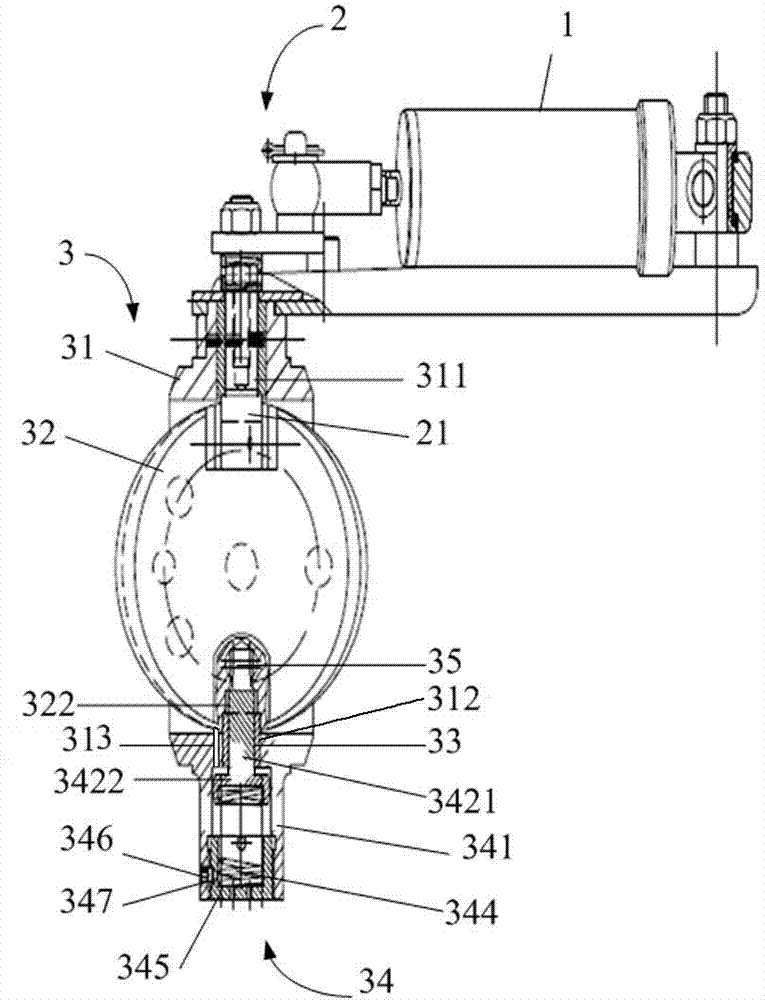

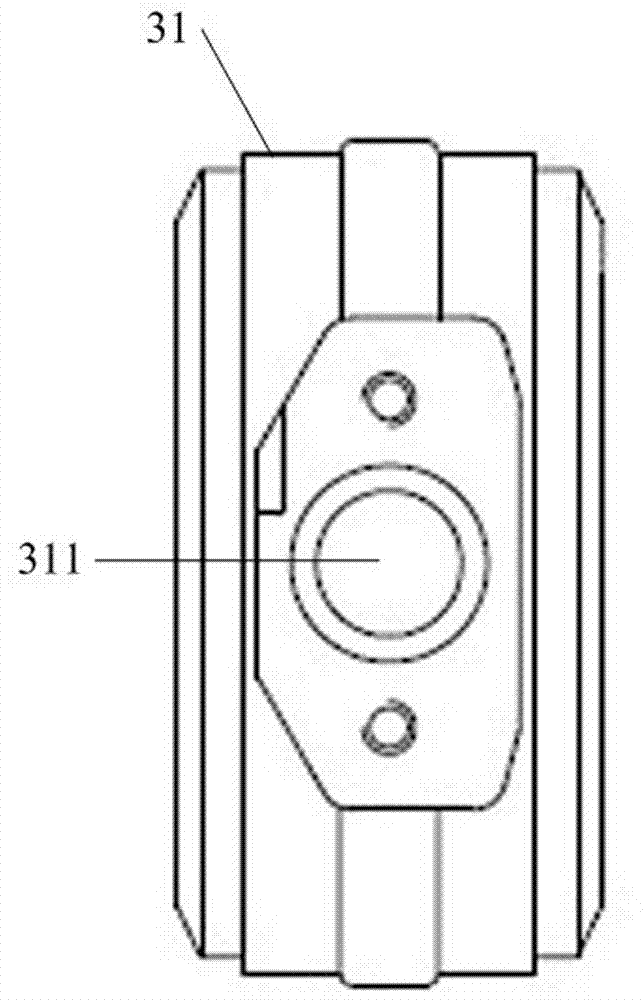

[0036] Please refer to figure 1 The schematic diagram of the auxiliary brake valve of the present invention, the auxiliary brake valve is mainly compos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com