Pineapple/coix lachryma-jobi kernel spirit and preparation method thereof

A technology of barley wine and pineapple, applied in the field of beverage wine, can solve the problems of singleness of nutritional components and health care functions, and achieve the effect of rich protein content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

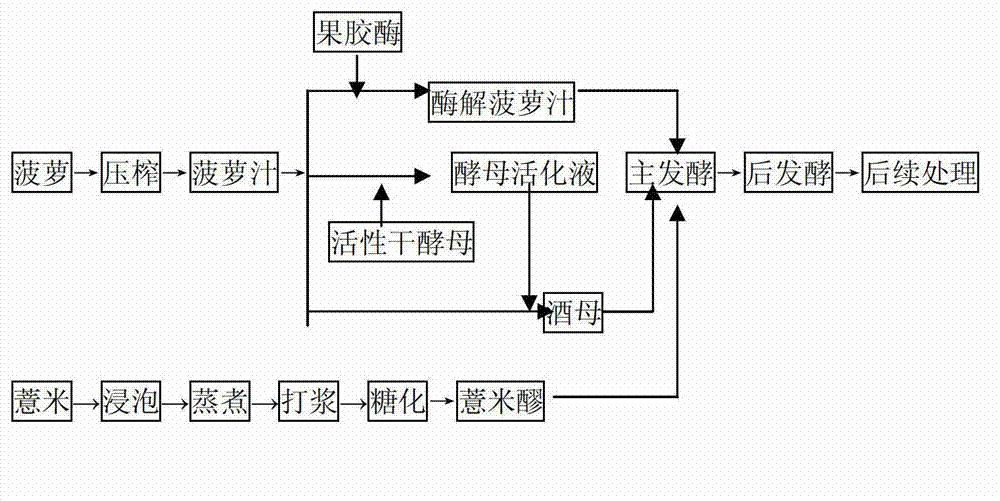

Image

Examples

Embodiment 1

[0033] (1) Squeeze and enzymatic hydrolysis of pineapple juice

[0034] Put the pineapple in a press to squeeze the juice; add pectinase to the pineapple juice in an amount of 60 mg / l, stir well and leave it to stand to obtain the enzymolysis pineapple juice;

[0035] (2) Preparation of barley mash

[0036] Soak barley in a steamer and steam until cooked, add water to beat, then add amylase, keep warm at 80°C for 50 minutes, lower the temperature to 40°C, add pectinase, keep warm for 6 hours, and use 1 part by weight of barley, water The add-on of amylase is 0.4 weight part, the add-on of amylase is 0.001 weight part, and the add-on of pectinase is 0.005 weight part;

[0037] (3) Preparation of distiller's mother

[0038] Inoculate active dry yeast with a mass percentage of 8% into pineapple juice and activate it for 1 hour to obtain a yeast activation liquid. Inoculate the yeast activation liquid into pineapple juice at an inoculation amount of 12% by mass percentage and cu...

Embodiment 2

[0044] (1) Squeeze and enzymatic hydrolysis of pineapple juice

[0045] Put the pineapple in a press to squeeze the juice; add pectinase to the pineapple juice in an amount of 100mg / l, stir well and let stand to obtain the enzymolysis pineapple juice;

[0046] (2) Preparation of barley-glutinous rice mash

[0047]Mix barley and glutinous rice evenly in a mass ratio of 1:2, soak and steam in a steamer, add water to beat, then add glucoamylase, keep warm at 120°C for 20 minutes, lower the temperature to 60°C, add Daqu, and keep warm for 2 hours and based on 1 part by weight of barley / glutinous rice, the addition of water is 0.8 parts by weight, the addition of glucoamylase is 0.005 parts by weight, and the addition of Daqu is 0.001 parts by weight;

[0048] (3) Preparation of distiller's mother

[0049] Inoculate active dry yeast with a mass percentage of 12% into pineapple juice, activate for 3 hours to obtain a yeast activation solution, inoculate the yeast activation soluti...

Embodiment 3

[0055] (1) Squeeze and enzymatic hydrolysis of pineapple juice

[0056] Put the pineapple in a press to squeeze the juice; add pectinase to the pineapple juice in an amount of 70 mg / l, stir well and leave it to stand to obtain the enzymolysis pineapple juice;

[0057] (2) Preparation of barley-glutinous rice mash

[0058] Mix barley and glutinous rice evenly in a mass ratio of 2:1, soak and steam in a steamer, add water to beat, then add amylase, keep warm at 90°C for 40 minutes, lower the temperature to 50°C, add pectinase , kept for 4 hours, and based on 1 part by weight of barley / glutinous rice, the addition of water is 0.5 parts by weight, the addition of amylase is 0.003 parts by weight, and the addition of pectinase is 0.002 parts by weight;

[0059] (3) Preparation of distiller's mother

[0060] Inoculate active dry yeast with a mass percentage of 10% into pineapple juice and activate for 1.5h to obtain a yeast activation solution. The yeast activation solution is ino...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com