Clay-content-free drilling fluid

A technology without clay and drilling fluid, applied in the direction of drilling composition, chemical instruments and methods, etc., which can solve the problems of large fluid loss and reduced reservoir permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

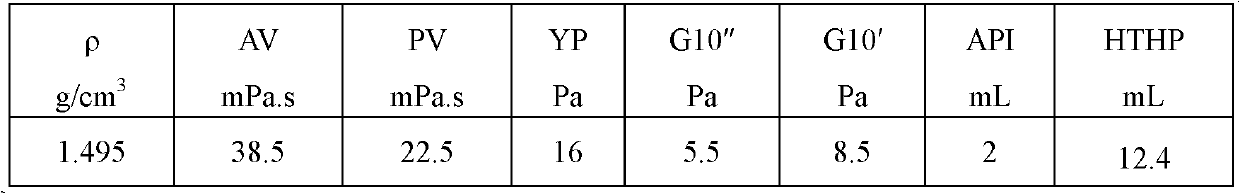

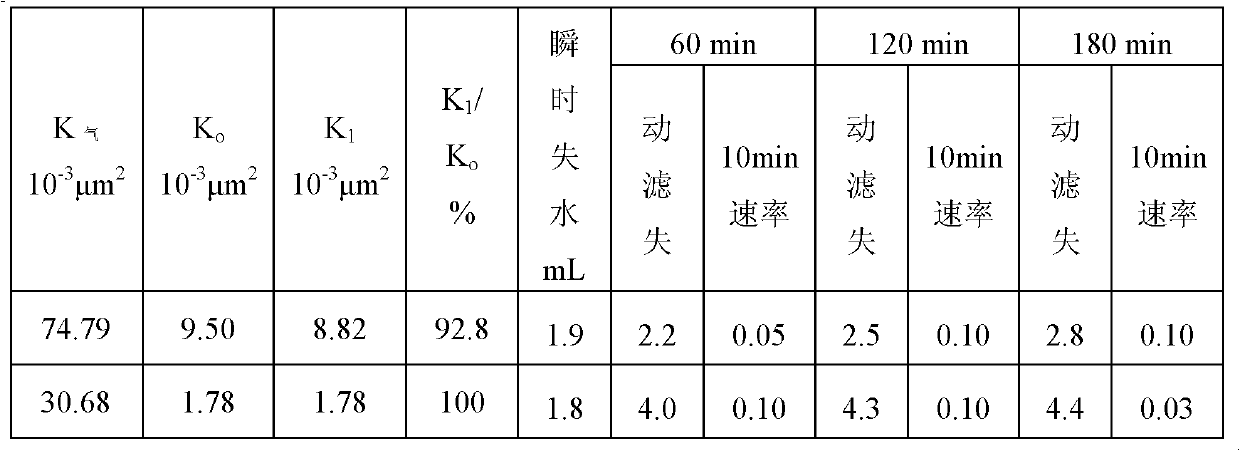

[0058] The purpose of the present invention is to develop a clay-free drilling fluid system that can effectively seal in low-porosity and low-permeability reservoirs. The technical solution is that the drilling fluid is composed of seawater, viscosifier, fluid loss It is composed of plugging agent, inhibitor and weighting agent, wherein seawater is the base fluid, and then viscosity increaser, fluid loss reducer, plugging agent, inhibitor, and weighting agent are added according to the ratio of the components to the base fluid. It is preferably suitable for resistance to 150°C, 1.2 and 1.5g / cm 3 Viscosifier, fluid loss reducer and plugging agent for clay-free drilling fluid system.

[0059] The specific implementation manners of the present invention will be described in detail below in combination with actual conditions.

[0060] When the present invention is implemented, the drilling fluid is composed of seawater, viscosifier, fluid loss reducer, plugging agent, inhibitor a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com