Light-and-temperature-induced color change masterbatch and preparation process thereof

A preparation process and technology of color masterbatch, which is applied in the field of light-temperature-sensitive color-changing masterbatch and its preparation technology, can solve the problems of color change of color masterbatch and inability to adapt to industry requirements, etc., and achieve reasonable structure design, low preparation cost, and easy preparation The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The photo-temperature-sensitive color-changing masterbatch described in this embodiment is cylindrical and includes a carrier. The outer part of the carrier is covered with a photosensitive layer made of a photosensitive color-changing material, and the remaining part is covered with a temperature-sensitive layer made of a thermochromic pigment , The thickness of the photosensitive layer is 0.5mm, and the thickness of the temperature-sensitive layer is 0.5mm.

[0033] The preparation process of the above-mentioned light-temperature sensitive color-changing masterbatch includes the following process steps:

[0034] 1. Grinding

[0035] Prepare two grinding vessels, one of which is to put photosensitive color-changing material, water, and dispersant in a mass ratio of 7:5:2, and then fully grind to form photosensitive color-changing particles with a diameter of 1μm; the other is a grinding vessel Add the thermochromic pigment, water, and dispersant to the mixture, mix the three...

Embodiment 2

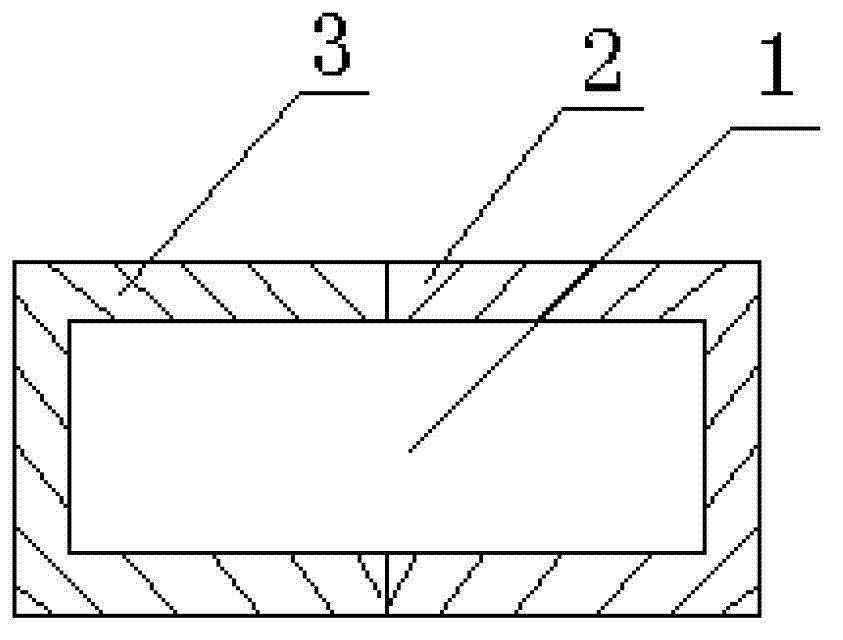

[0045] With reference to the drawings, the photo-temperature-sensitive color-changing masterbatch described in this embodiment is in the shape of a square sheet, and includes a carrier 1. The outer part of the carrier 1 is covered with a photosensitive layer 2 made of a photosensitive color-changing material, and the remaining part is covered with a temperature-sensitive For the temperature sensitive layer 3 made of color-changing pigment, the thickness of the photosensitive layer 2 is 1 mm, and the thickness of the temperature sensitive layer 3 is 1 mm. The shape of the masterbatch is a square plate.

[0046] The preparation process of the above-mentioned light-temperature sensitive color-changing masterbatch includes the following process steps:

[0047] 1. Grinding

[0048] Prepare two grinding vessels, one of which is to put photosensitive color-changing material, water, and dispersant in a mass ratio of 9: 7: 4 and then fully grind to form photosensitive color-changing particle...

Embodiment 3

[0058] The photo-temperature-sensitive color-changing masterbatch described in this embodiment is round and includes a carrier. The outer part of the carrier is covered with a photosensitive layer made of a photosensitive color-changing material, and the remaining part is covered with a temperature-sensitive layer made of a thermochromic pigment 3. The thickness of the photosensitive layer is 0.8mm, and the thickness of the temperature-sensitive layer 3 is 0.8mm; the color masterbatch.

[0059] The preparation process of the above-mentioned light-temperature sensitive color-changing masterbatch includes the following process steps:

[0060] 1. Grinding

[0061] Prepare two grinding vessels, one of which puts photosensitive color-changing material, water, and dispersant in a mass ratio of 8:6:3 and then fully grinds them to form photosensitive color-changing particles with a diameter of 1.5μm; the other Put the thermochromic pigment, water, and dispersant into the grinding vessel, mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com