Adjustable hanging hook

A technology of hooks and movable hooks, applied in the direction of load hanging components, transportation and packaging, etc., to achieve the effects of wide application range, guaranteed lifting effect, and improved product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

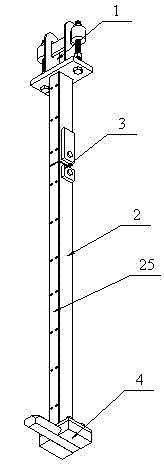

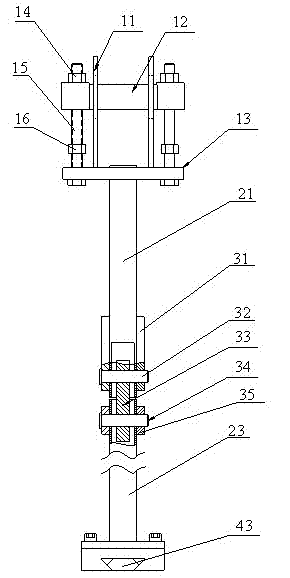

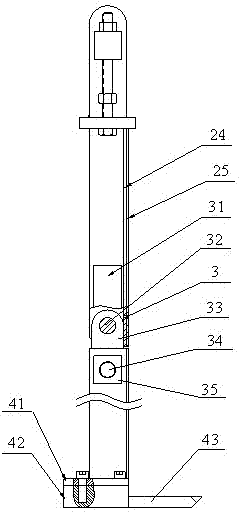

[0016] As shown in the figure, this embodiment includes a height adjustment mechanism 1, a column 2 and a base 4. Among them, the height adjustment mechanism 1 includes a supporting plate 13 with longitudinal threaded holes at both ends of the supporting plate 13 and bolts 15 respectively screwed to it. In the middle of the upper surface of the support plate 13, two longitudinal tension plates 11 are vertically fixed, and the upper part of each tension plate 11 has a longitudinal long hole. Above the support plate 13, a cross beam 12 is provided with longitudinal light holes at both ends. The size of the elongated hole on the two tension plates 11 is adapted to the cross-sectional size of the beam—its width is slightly larger than the thickness of the beam 12, and its length is larger than the height of the beam 12. The cross beam 12 passes through the elongated holes of the two tension plates 11, the thickness direction of which is dynamically matched with the elongated holes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com