Purifying device for welding fume

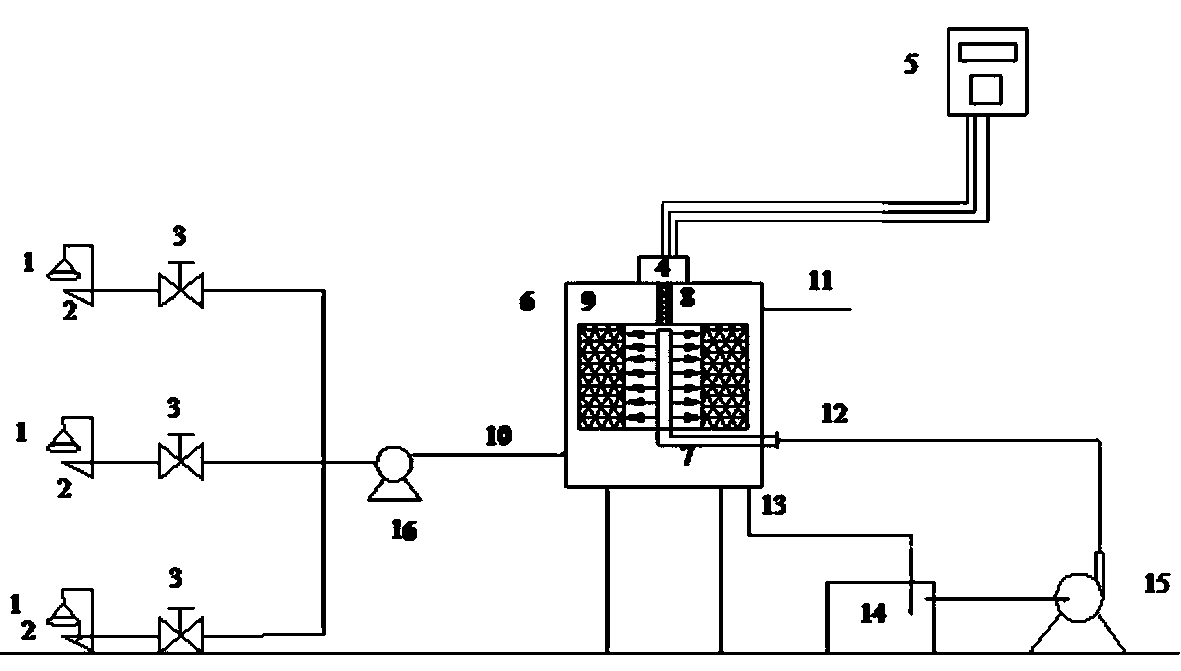

A welding fume purification and welding torch technology, applied in the direction of removing fume, auxiliary devices, combined devices, etc., can solve the problem that the dust removal method is not suitable for electric welding fume control, etc., and achieves the effect of small footprint, low energy consumption, and easy movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

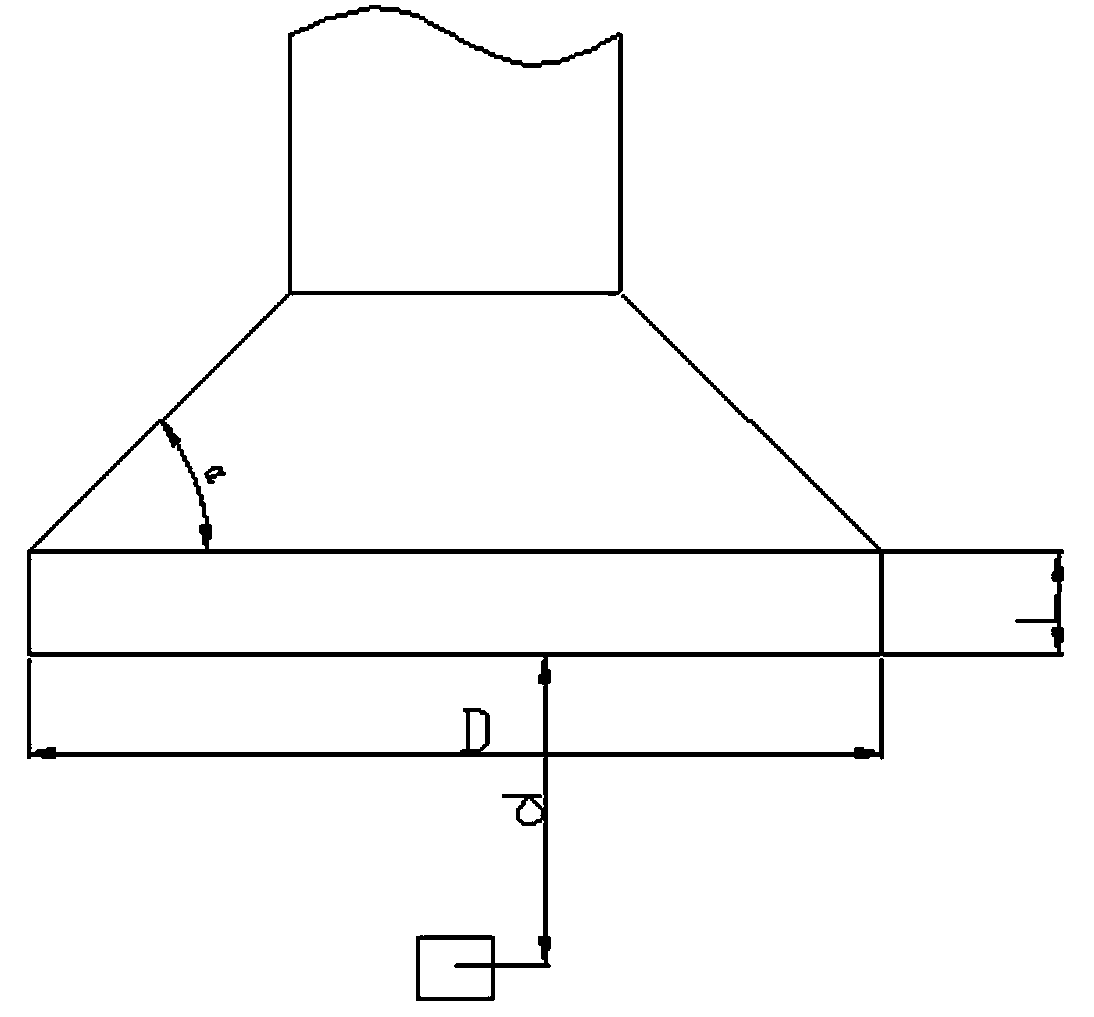

[0035] Purify the smoke and dust produced by T422 titanium-calcium type low-carbon steel welding rod, and test the contents of the substances contained in the welding smoke to be MnO 2 The content is 0.63mg / m 3 、TiO 2 The content is 0.2mg / m 3 , Dust content is 8.35 mg / m 3 1. The average particle size of smoke and dust is 0.3μm. During the production process, the smoke and dust generated by ten welding machines are purified. Ten sets of gas collecting hoods are connected in parallel, and the gas collecting hoods are connected directly above the welding torch. Water is used as the absorbent in the test. The size ratio of the gas collecting hood is: the distance from the dust source to the hood mouth d=1 / 2 the diameter D of the ring part; the height of the skirt of the ring part L=1 / 2 the diameter D of the ring part; 60°.

[0036] First turn on the induced draft fan, adjust the valve so that the gas collection hood speed is 1.0m / s, the gas pipeline gas speed is 15m / s, and the...

Embodiment 2

[0038] Purify the fumes produced by J44 welding rods, and test the contents of the substances contained in the welding fumes to be Fe 2 o 3 The content is 8.3mg / m 3 , CaO content is 3.2mg / m 3 , Dust content is 6.35 mg / m 3 , The average particle size of smoke and dust is 0.4μm. During the production process, the smoke and dust generated by five electric welding machines are purified. The five gas collecting hoods are connected in parallel, and the gas collecting hoods are connected to the side of the welding torch. Water is used as the absorbent in the test. The size ratio of the gas collecting hood is: the distance from the dust source to the hood mouth d=2 the diameter D of the ring part; the height of the skirt of the ring part L=1 / 4 the diameter D of the ring part; the angle α between the table part and the ring part=30° .

[0039] By adjusting the valve, the gas velocity of the gas collecting hood is 0.3m / s, the gas velocity of the gas pipeline is 10m / s, and the total ...

Embodiment 3

[0041] Purify the smoke and dust produced by the 507-type welding rod, and test the content of the substances contained in the welding smoke to be Fe 2 o 3 The production rate is 83mg / min, SiO 2 The content is 22mg / min, CaF 2 30mg / min, the average particle size of the dust is 0.35μm. During the production process, the smoke generated by 3 welding machines is purified. The 3 gas collecting hoods are connected in parallel, and the gas collecting hood is connected to the side of the welding torch. Water is used as the absorbent in the test. The size ratio of the gas collecting hood is: the distance between the dust source and the hood mouth d=the diameter D of the ring part; the height of the skirt of the ring part L=1 / 3 the diameter D of the ring part; the angle α between the table-shaped part and the ring part=45°.

[0042] By adjusting the valve, the gas velocity of the gas collecting hood is 2.5m / s, the gas velocity of the gas pipeline is 25m / s, and the total gas flow rate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com