Superconducting claw-pole motor

A claw-pole motor and superconducting technology are applied in the field of superconducting claw-pole motors to achieve the effects of improving electrical conversion efficiency, small processing volume, and no eddy current loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

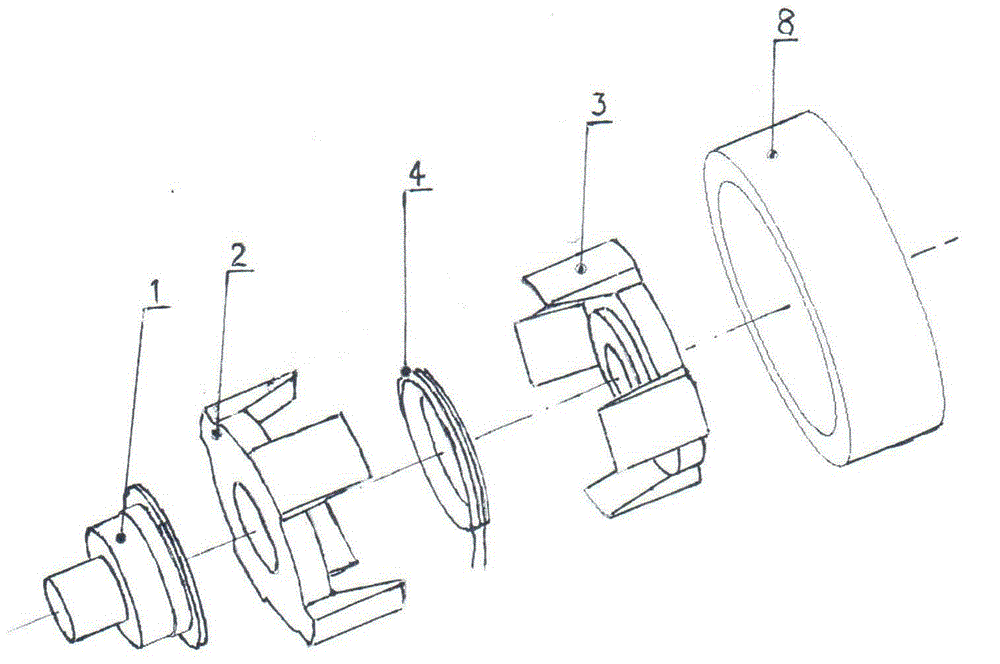

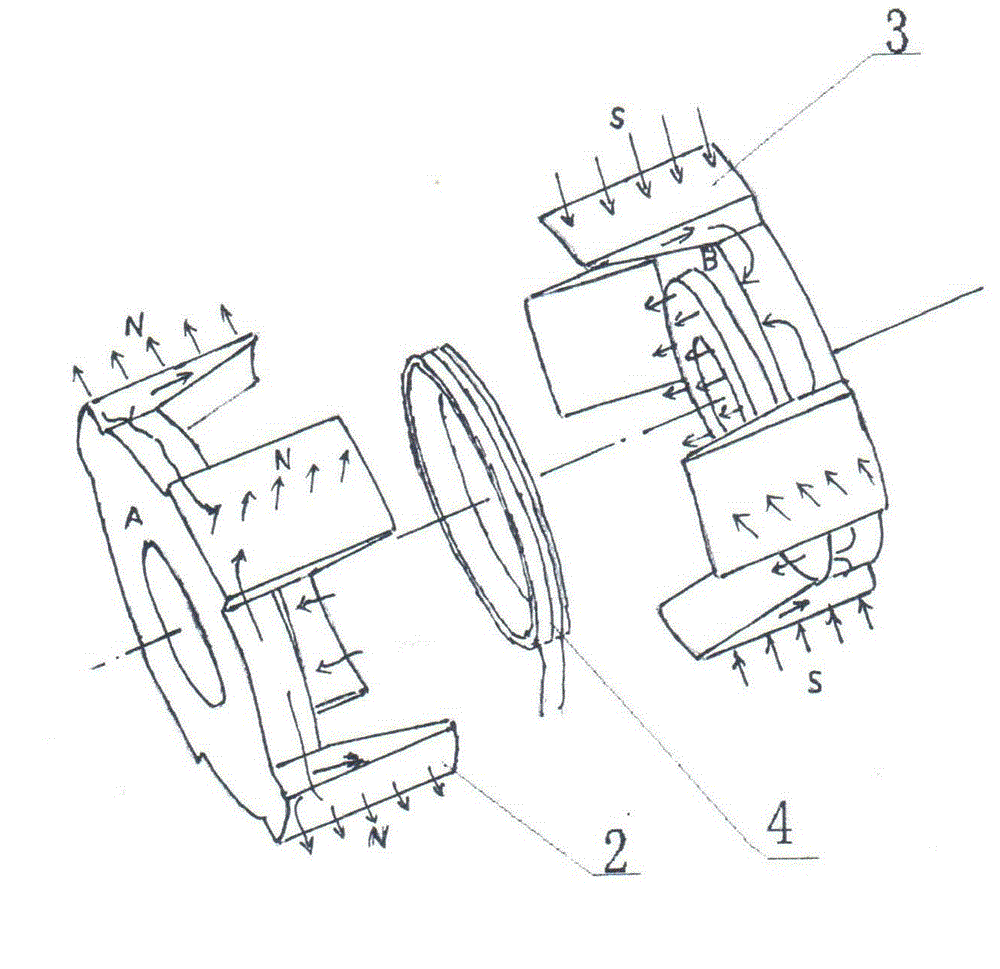

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. Because the article is written non-exhaustively, the described implementation, the number of claw pole pairs, the position of N and S poles, the material and forming method of the rotor yoke, the number of stator armatures and yokes, whether used for motors or Generators, neither limit similar variants of the embodiment of the invention.

[0023] The invention provides a new design method of a superconducting motor. The superconducting strip or wire is looped around the axis on a fixed support, the support is installed on the hollow support shaft, and the superconducting winding A refrigerant circulation space and a Dewar structure are formed around it to form a superconducting excitation part. Two corresponding magnetic yoke claw poles are buckled on both sides of the superconducting excitation winding. When the superconducting excitat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com