26/35kV or 27.5kV silicon rubber cold contraction type through joint

A straight-through joint, silicone rubber technology, applied in the direction of electrical components, cable accessories, cable installation, etc., can solve the problems that the silicone rubber cold-shrink straight-through joint cannot be performed, cannot guarantee long-term operation, and is not suitable for intermediate joints, etc. The effect of small partial discharge, optimized electric field distribution, and improved electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

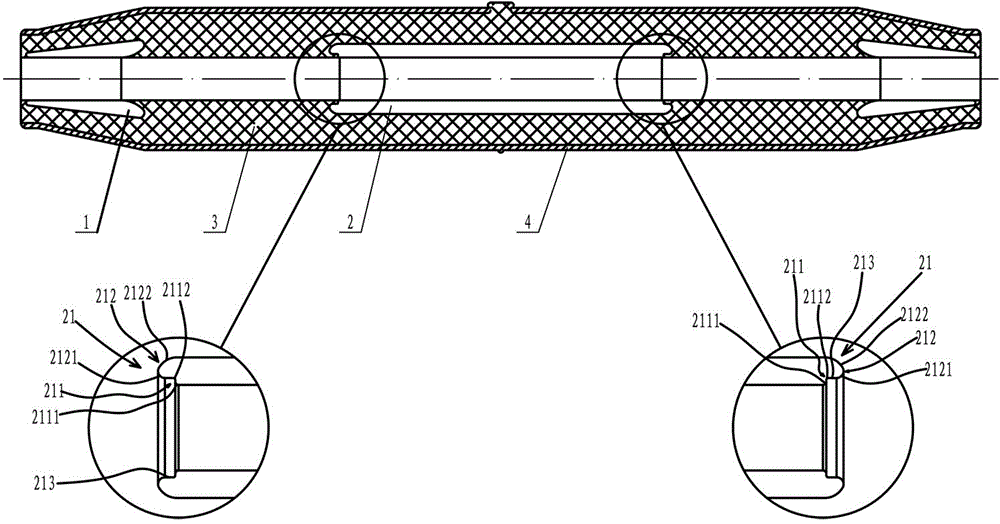

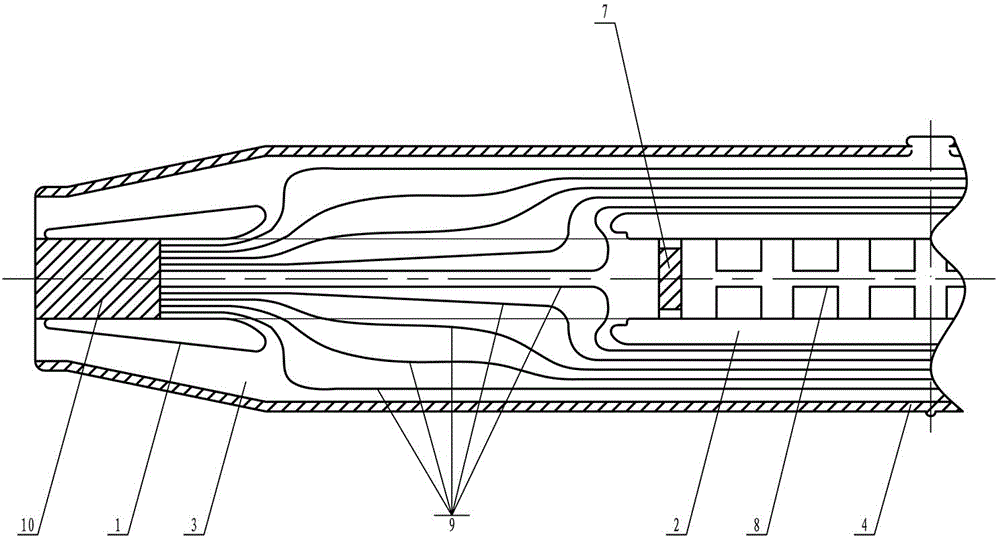

[0018] See Figure 1 to Figure 3 , Figure 1 to Figure 3 Disclosed is a 26 / 35kV or 27.5kV silicone rubber cold-shrinkable straight-through joint, including an insulating layer 3, an outer shielding layer 4 is provided on the outer surface of the insulating layer 3, and an outer shielding layer 4 is provided on the inner wall of the middle part of the insulating layer 3. Composite with a pressure equalizing tube 2, a stress cone 1 is provided on the inner wall at both ends of the insulating layer 3, and a double cone structure 21 is respectively provided at both ends of the pressure equalizing tube 2, each of the double cones The structure 21 includes an outwardly expanding inner cone 211 and an outer cone 212 , the inner cone 211 and the outer cone 212 are transitionally connected by a circular tube 213 whose diameter is larger than the inner diameter of the pressure equalizing tube 2 . The length of the equalizing tube 2 can be selected between 180-250mm, and the thickness o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com