Visual field eliminating rotation mechanism of horizontal telescope

A technology for rotating mechanisms and telescopes, applied in telescopes, optics, instruments, etc., can solve problems such as time delay, signal-to-noise ratio drop, complex structural design and adjustment, and achieve high rotation accuracy and high rotation positioning accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

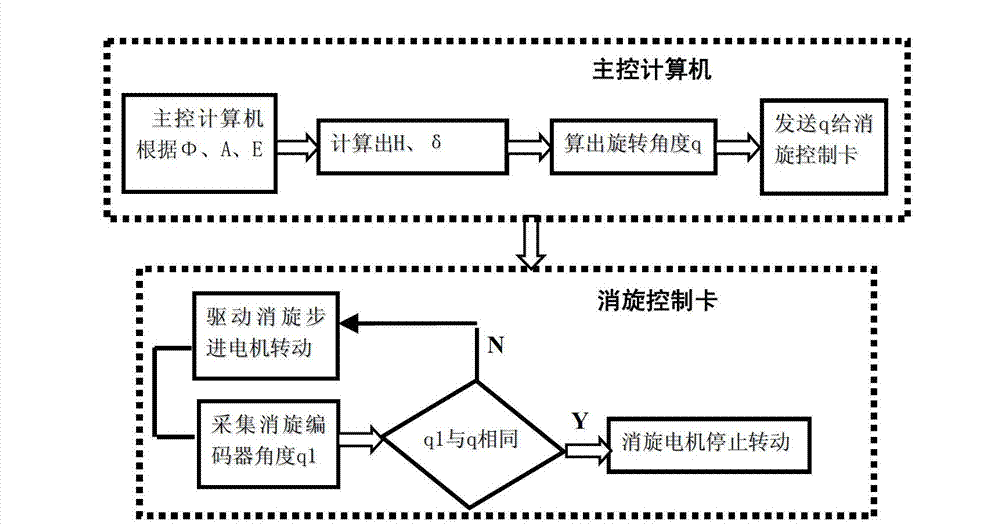

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

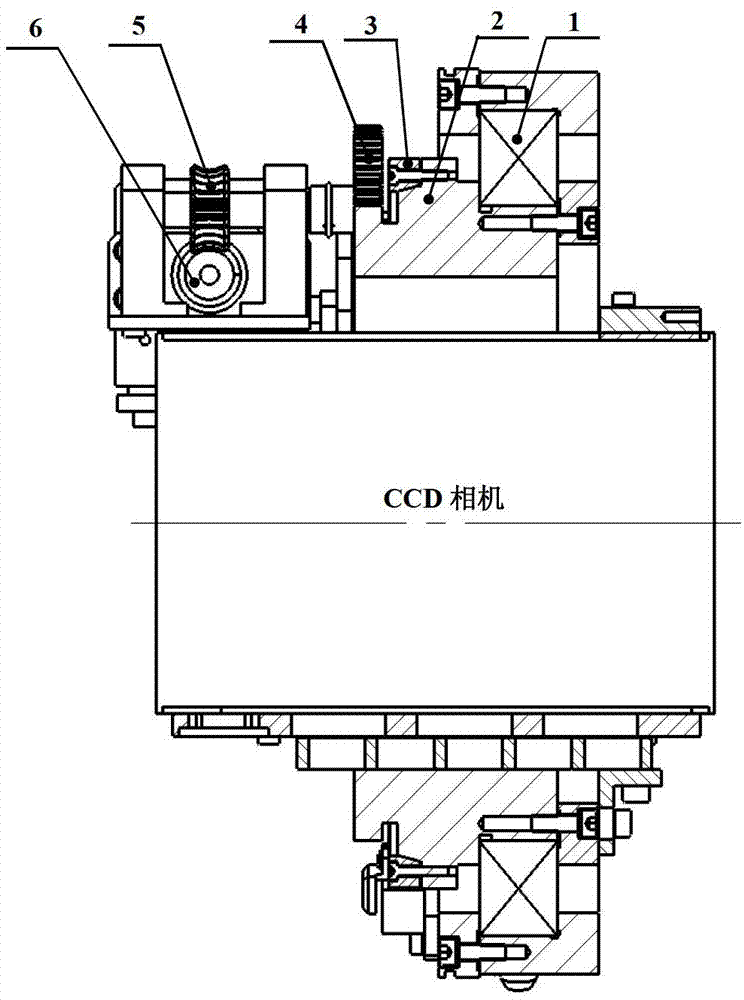

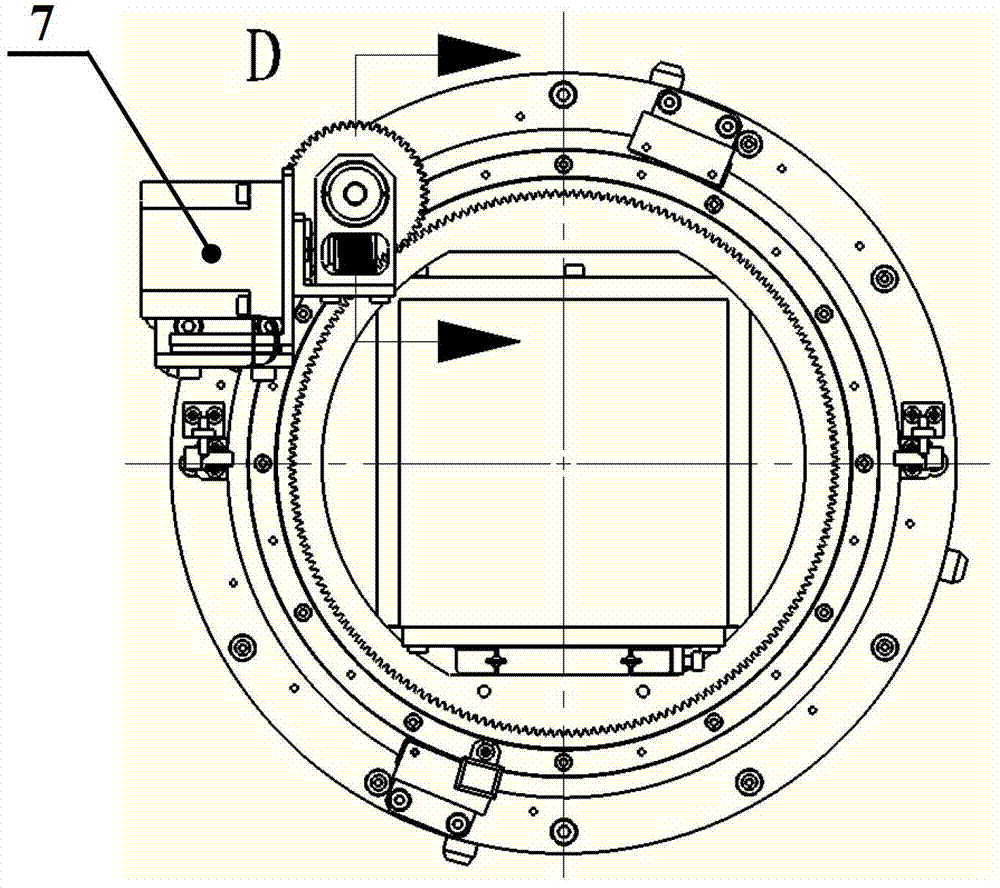

[0019] The invention provides a horizon-type telescope disappearing field rotating mechanism, which includes a cross roller bearing 1, a driven spur gear 2, a driving spur gear 4, a metal reflective circular grating encoder 3, a turbine 5, Worm screw 6, stepping motor 7 and CCD camera;

[0020] The stepper motor 7 is used to drive the worm 6, the worm 6 drives the turbine 5, the turbine 5 drives the driving spur gear 4, and the driving spur gear 4 drives the driven spur gear 2 to rotate to drive the CCD camera to rotate ; The drive and driven spur gears, the worm gear and the worm adopt two-stage transmission to achieve a larger transmission ratio;

[0021] The metal reflective circular grating encoder 3 is used for the measurement of the rotation angle during the rotation of the CCD camera;

[0022] The metal reflective circular grating enco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com