Drum-type coal cutter rocker arm

A shearer and drum-type technology, applied in the field of drum-type shearer components, can solve problems such as unreasonable structural design and unsatisfactory internal lubrication, and achieve the effect of novel structure, compact structure and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

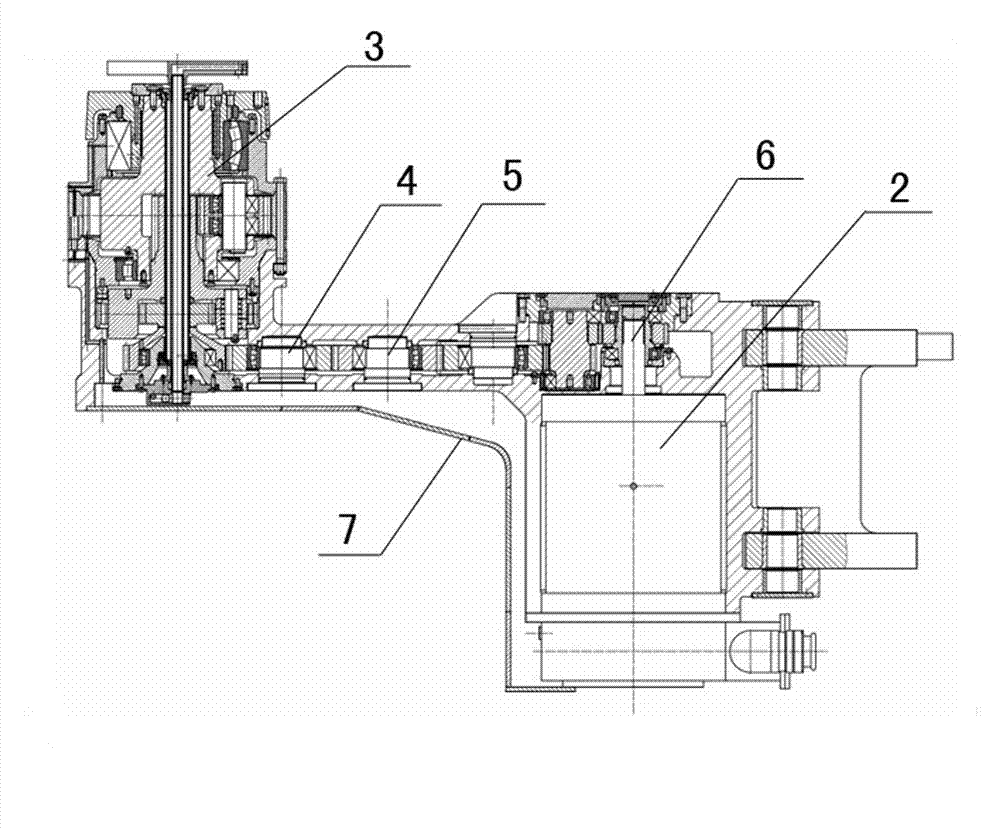

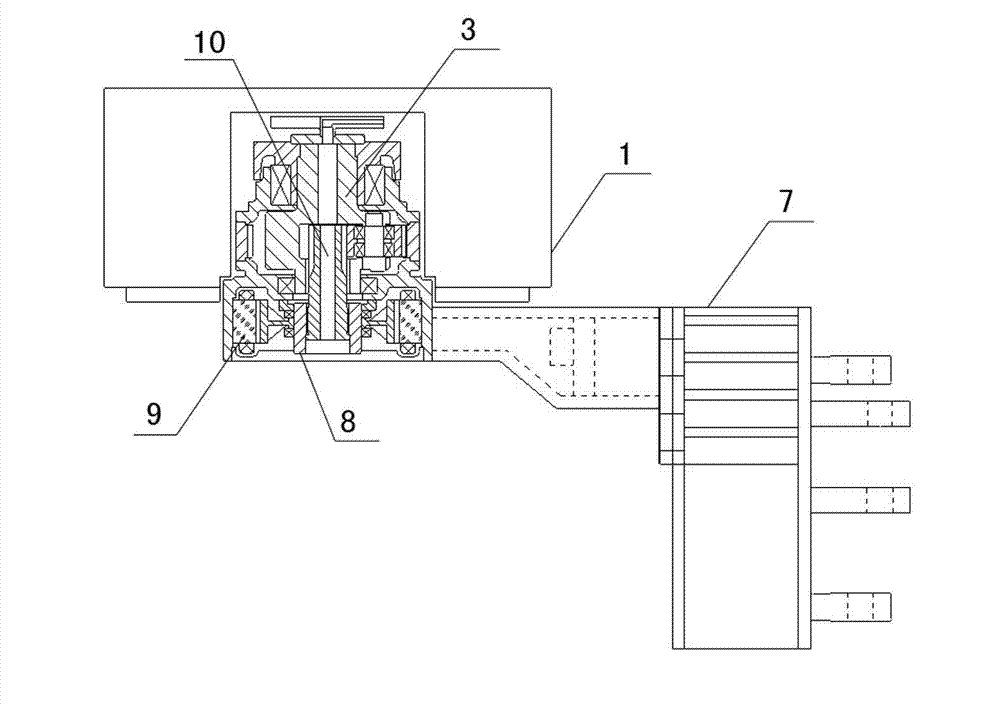

[0012] The rocker arm of the drum shearer includes a rocker housing 7 and a reduction transmission system. The reduction transmission system is composed of a planetary reducer 3 located at the inner head of the rocker housing 7. The coal mining The rocker arm also includes a low-speed high-torque permanent magnet motor longitudinally arranged below the planetary reducer 3 in the rocker arm housing 7. The permanent magnet motor includes an inner rotor 8 and an outer stator 9. The permanent magnet motor is fixed on the The spline shaft 10 at the center of the inner rotor 8 is drivingly connected with the planetary reducer 3 .

[0013] During specific implementation, the spline shaft 10 includes a shaft with a longitudinal groove on the outside and a rotating member sleeved on the shaft and rotating synchronously with the shaft. The output shaft of the permanent magnet motor is the shaft of the spline shaft 10 , and the input shaft of the planetary reducer 3 is the rotating p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com