Linear motor drive device of shifting door

A technology of linear motors and linear guide rails, applied in the direction of electromechanical devices, electric components, electrical components, etc., can solve the problems of large space occupation, hidden safety hazards, complex switching mechanisms, and high difficulty in assembly, achieving low maintenance costs and good operation safety , long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

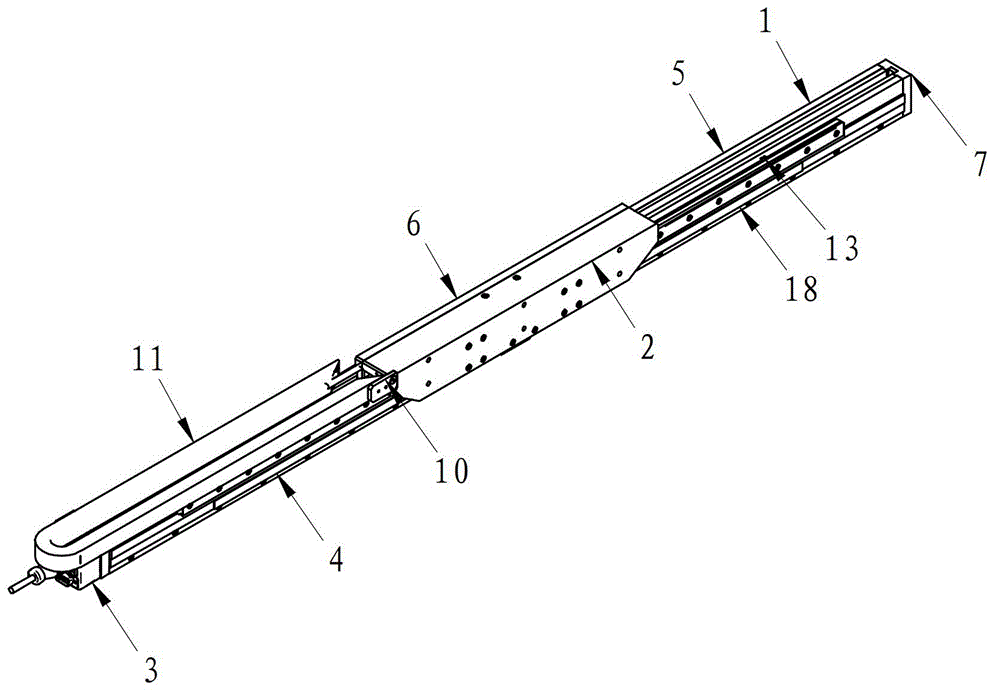

[0011] The main structure of this embodiment includes a linear motor assembly 1, a sliding assembly 2, an electrical assembly 3, a feedback assembly 4, a linear motor stator 5, a linear motor 6, a limit seat 7, a sliding seat 8, a linear guide rail assembly 9, and a drag chain plate 10. Drag chain 11, Hall assembly 12, Hall magnet 13, electrical box 14, aviation plug 15, DB connector 16, reading head 17 and magnetic scale 18; linear motor assembly 1 consists of linear motor stator 5, linear electric The motor 6 and the limit seat 7 are assembled together. There are two limit seats 7, which are made of cuboid polyurethane material, and are respectively fixed on the two ends of the linear motor stator 5 with bolts; the sliding assembly 2 is composed of a sliding seat 8 and a linear guide rail assembly 9 , towline plate 10, towline 11 and Hall assembly 12 are assembled together; the sliding seat 8 is made of L-shaped aluminum alloy material, and is respectively connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com