Offset type solar orienting line light-condensing desert surface hardening system and hardening method

A solar energy and directional wire technology, which is applied in the field of solar energy utilization to achieve the effects of facilitating manufacturing, reducing costs, and preventing damage and destruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

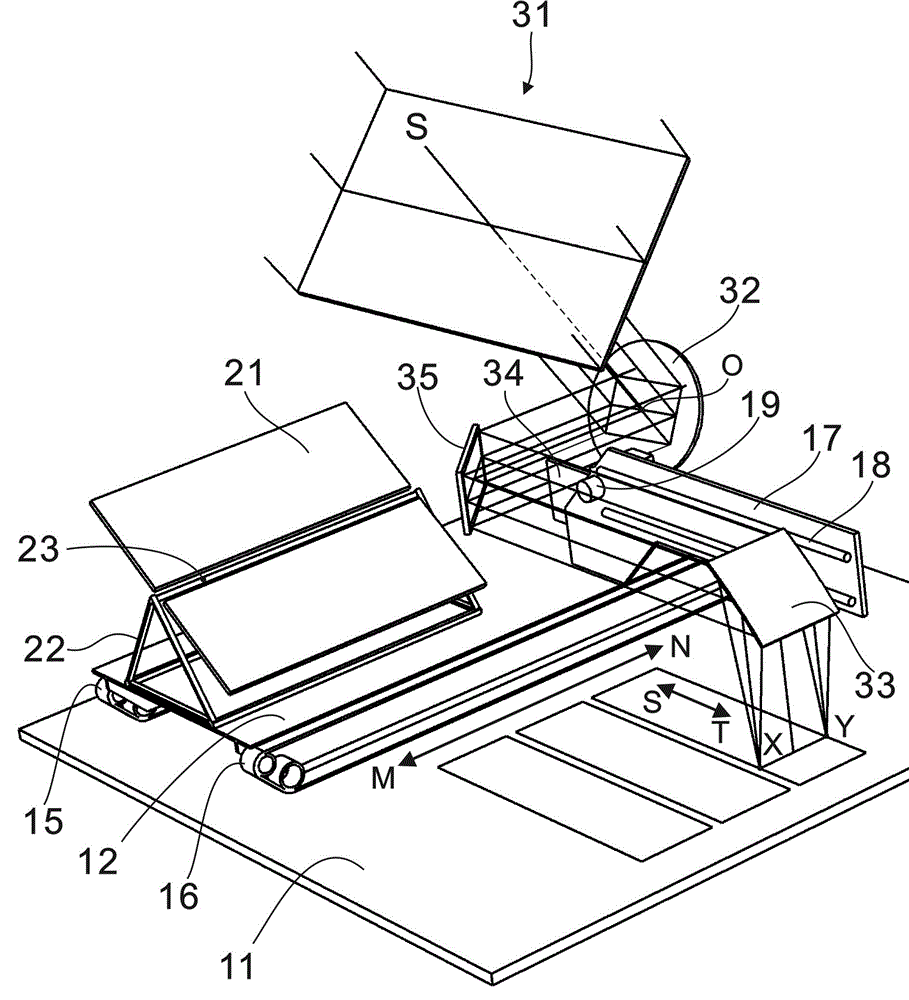

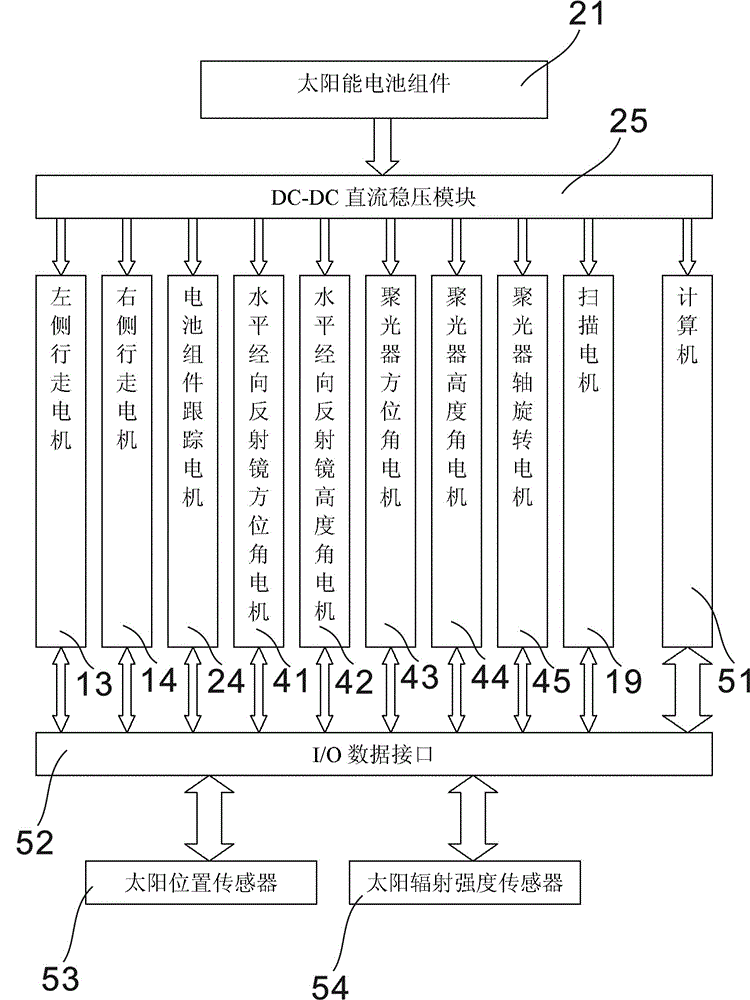

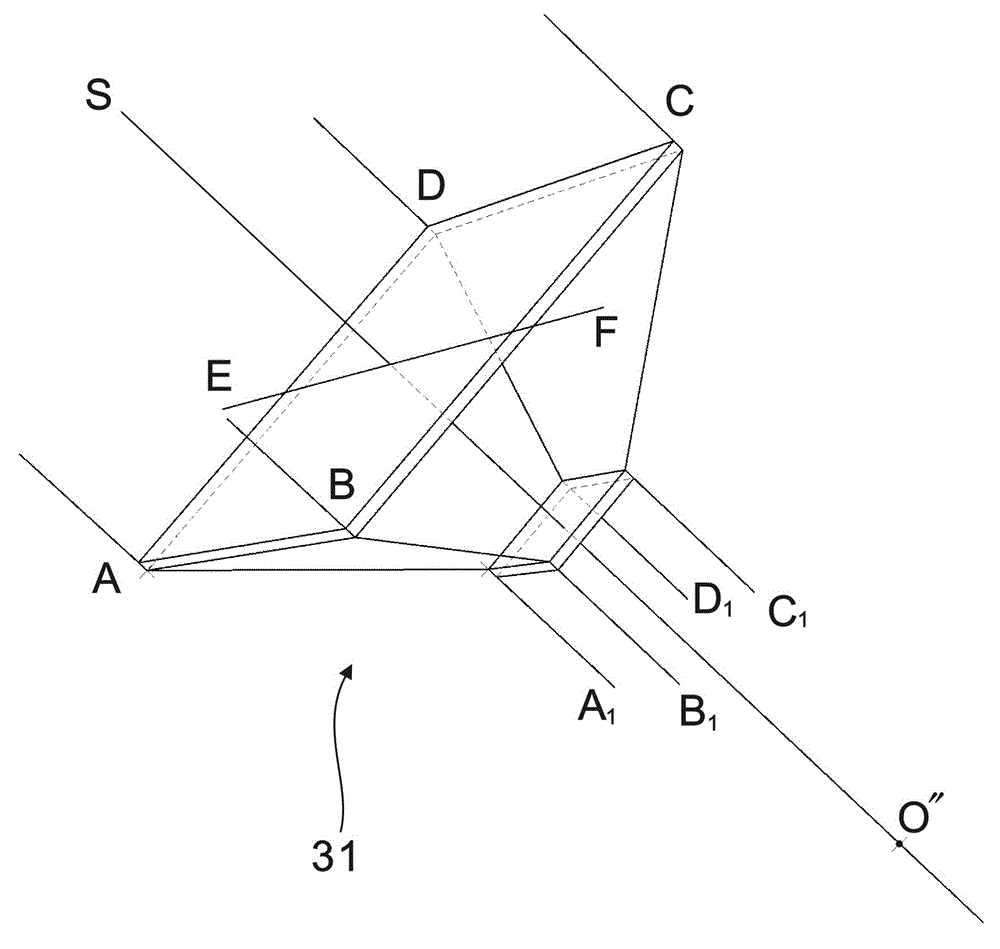

[0036] like figure 1 , figure 2 As shown, the present invention provides a kind of offset solar directional line concentrating desert surface hardening system, comprising horizontal sand surface 11, traveling mechanism 12, left side traveling motor 13, right side traveling motor 14, side traveling wheel belt 15, right Side travel wheel belt 16, offset bracket 17, scanning rail 18, scanning motor 19, solar battery module 21, battery module tracking bracket 22, tracking bracket rotation shaft 23, battery module tracking motor 24, DC-DC DC voltage stabilization module 25 , concentrator 31, horizontal longitude reflector 32, horizontal latitudinal reflector 35, parabolic cylindrical reflector 33, light-shielding reflector 34, horizontal longitude reflector azimuth motor 41, horizontal longitude reflector elevation angle motor 42. Concentrator azimuth motor 43, concentrator elevation angle motor 44, concentrator shaft rotation motor 45, computer 51, I / O data interface 52, sun pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com