Control method of high-temperature material conveying system

A control method and conveying system technology, applied in the direction of conveyor control device, conveyor objects, transportation and packaging, etc., can solve the problem of explosion-proof, flame-retardant, automatic loading, automatic unloading and automatic metering of high-temperature flammable materials and other problems to achieve the effect of preventing incomplete unloading and preventing material overflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

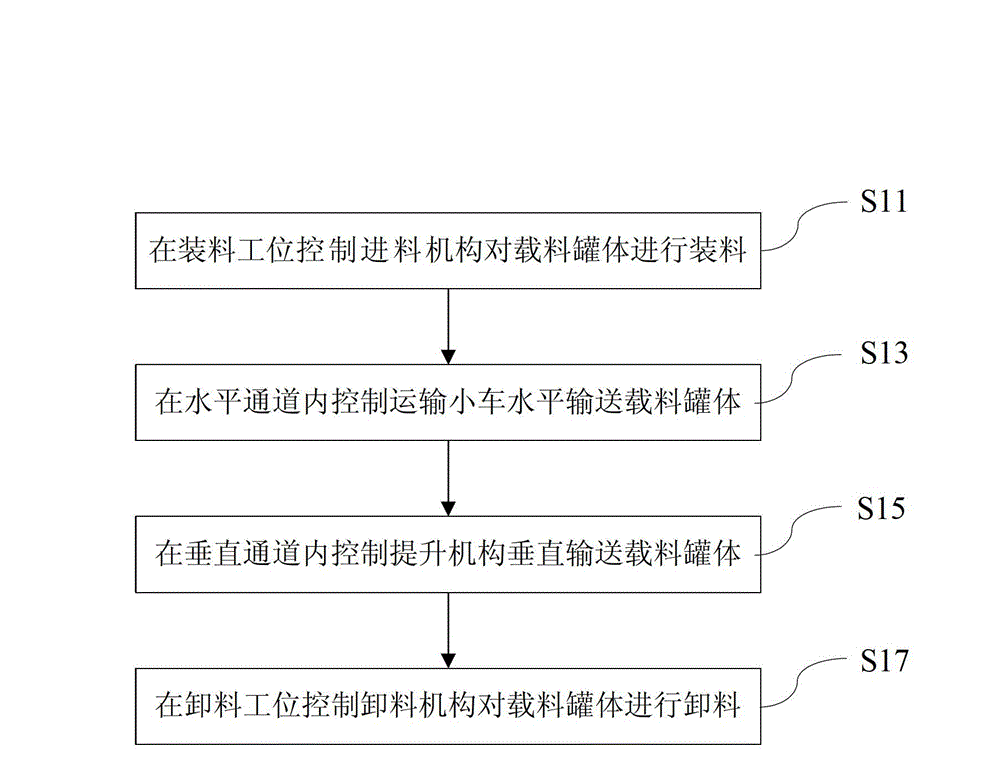

[0036] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

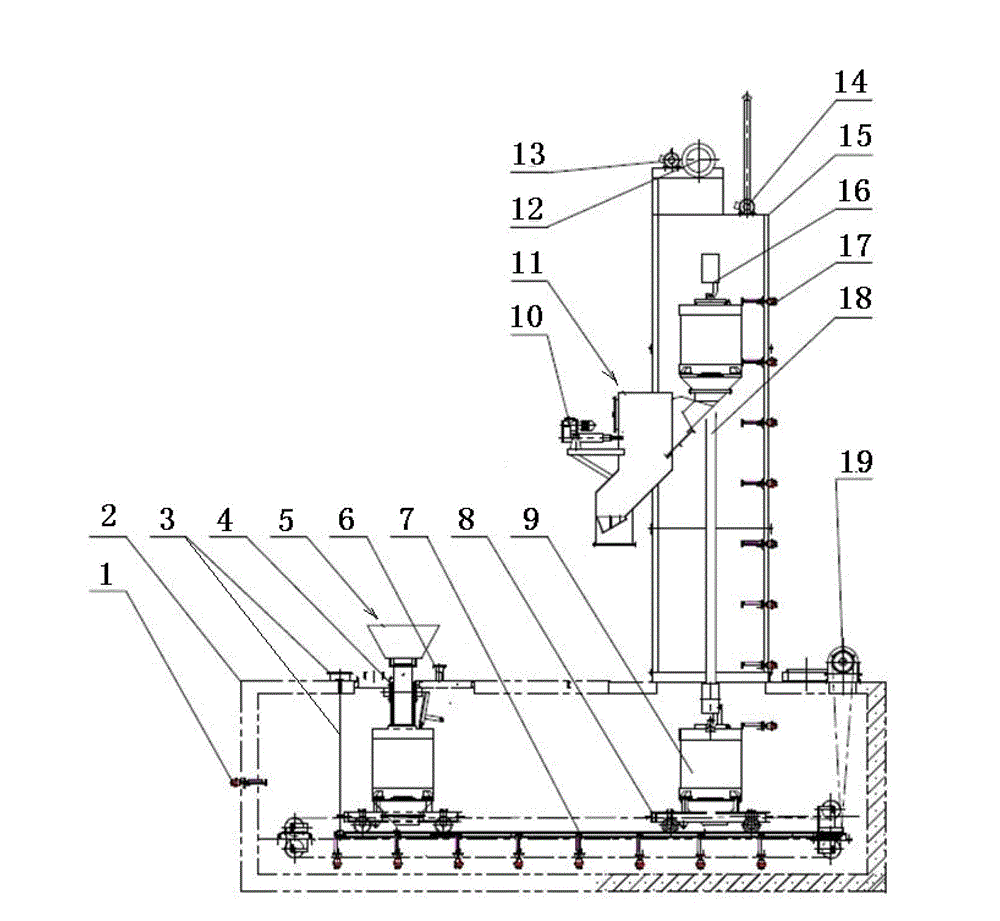

[0037] figure 1 It is a structural schematic diagram of the high-temperature material conveying system according to the present invention. Such as figure 1 As shown, the high-temperature material conveying system includes a horizontal channel 2 with a charging station 5, a vertical channel 15 with a discharge station 11, a transport trolley 8 set in the horizontal channel 2, and a The lifting mechanism, and the transport trolley 8 in the horizontal channel 2 is used to transport horizontally and the vertical channel 15 is transported vertically by the lifting mechanism, and the loading tank 9 is kept airtight during each delivery process.

[0038] Wherein, the horizontal passage 2 is provided with a horizontal guide rail 7 and a horizontal tractio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com