Drum Rotary Spiral Vibrating Screening Machine

A technology of drum screen and vibrating screen, which is applied in the direction of filter screen, solid separation, grid, etc. It can solve the problems of low screening energy, easy to stick to the screen, and small screening weight, so as to achieve high energy utilization rate and high screening efficiency. Obvious effects and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

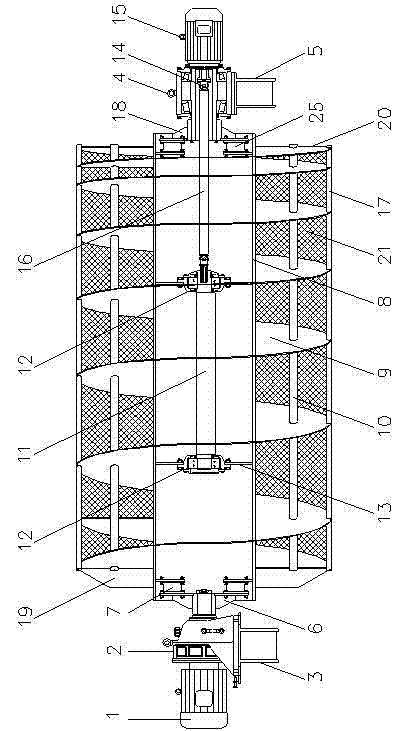

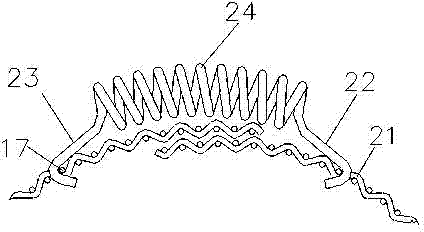

[0020] Such as figure 1 , 2 As shown, the drum-type rotating spiral vibrating screen machine includes a feed inlet 19, an outlet 20 for the screen material on the drum screen, a drum screen rotating motor 1, and a drum screen with a drum screen rotating bracket 3 connected to the drum screen rotating motor 1 The rotary speed reducer 2 and the rotary shaft connection plate 6 connected with the rotary screen rotary speed reducer 2, the rotary shaft connection plate 6 is connected with the rotary vibration collecting shaft tube 8 of the trommel screen through the first rubber shock absorber 7. An eccentric vibration collecting shaft 11 is installed inside the rotating vibration collecting shaft tube 8 of the trommel screen. 8-phase connection, the drum sieve rotating vibration-collecting shaft tube 8 is provided with a spiral blade 9 outside, and the screen horizontal support beam 17 connected with the screen 21 is fixedly installed on the outside of the spiral blade 9, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com