Side-exhaust exhaust valve bonnet

A technology of exhaust valve and bonnet, which is applied in the field of pressure cooker, can solve problems such as burns, and achieve the effect of reducing pressure, low cost, and reducing the risk of burns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

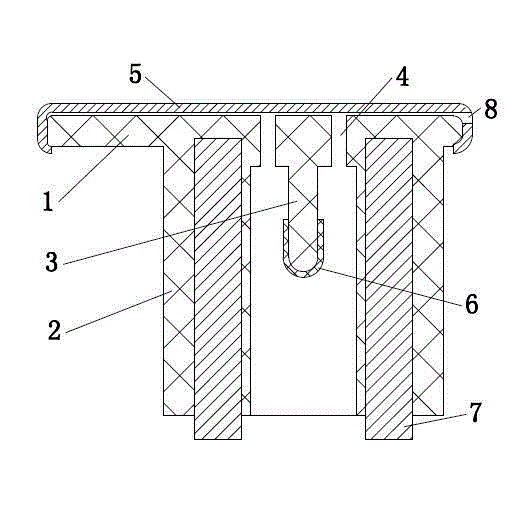

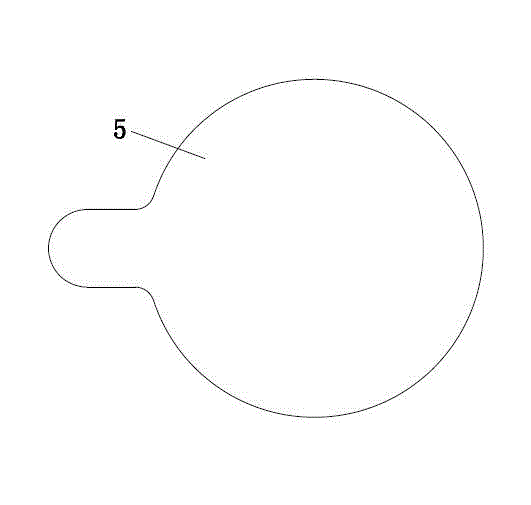

[0019] Such as figure 1 , figure 2 with image 3 The bonnet of an exhaust valve with side exhaust is shown, including a bonnet part 1, a valve body part 2, and a thimble part 3, wherein the bonnet part 1 is provided with an exhaust hole 4, and a gland is set on the bonnet part 1 5. A rectangular air outlet 8 is provided on the side of the gland 5 .

[0020] Wherein, the gland 5 is food-grade silica gel. The bonnet part 1, the valve body part 2, and the thimble part 3 are integrated, and the outside of the thimble part 3 is wrapped with a rubber sleeve 6. A counterweight steel core 7 is embedded in the valve body 2, which is convenient for production and assembly.

[0021] When this embodiment is in use, the gas is discharged from the exhaust hole 4, but due to the obstruction of the gland 5, the gas cannot be directly ejected upwards, but is ejected from the air outlet 8 on the side of the gland 5 to the side. Due to the increased flow distance of the gas, it can not onl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com