Resilient sheet type green peel stripping machine of sigillate walnut

A technology of soaking walnuts and green skin machines, which is applied in the fields of shelling, pod removal, food science, etc. It can solve the problems of water ingress in the fruit, economic benefits outweigh the benefits, and no way to deal with it, and achieve the effect of increasing adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

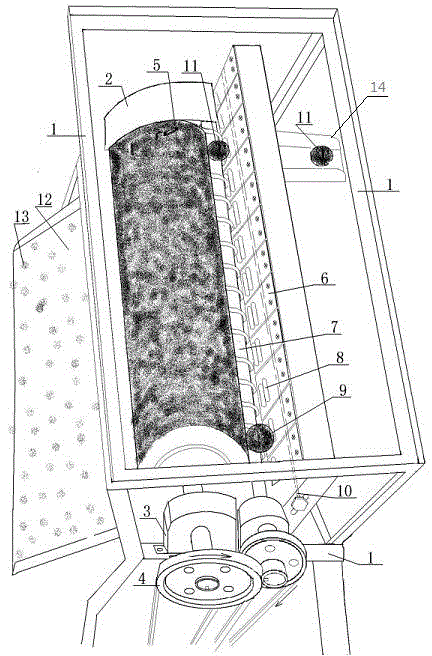

[0015] Such as figure 1 Shown is the structural representation of the present invention, and principle of work is: according to the average size and maturity of green walnut fruit, move the position of pressure regulating lever 10 to regulate the elastic pressure of each spring sheet of spring pressure sheet assembly 6, then unpeeled The green walnut fruit 9 is sent into the long groove-shaped processing cavity in the middle of the frame. When the machine is working normally, the green peel is peeled off under the extrusion of the rotating wire wheel shaft 5, the spring pressure plate assembly 6 and the rotating screw shaft 7. A plurality of parallel resistance strips are arranged on the side of each spring pressure piece facing the walnut fruit, which can effectively increase the efficiency of peeling off the green skin; Block; the walnut fruit 11 peeled off the green peel comes out from the fruit outlet 14, and the peeled walnut green peel 13 is discharged from the slag outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com