Vacuum arc extinguishing chamber positioning and sealing ring

A vacuum interrupter and sealing ring technology, which is applied to high-voltage air circuit breakers, electrical components, electric switches, etc., can solve the problem that the sealing ring cannot be adapted to the mass production of vacuum interrupters, the production efficiency of vacuum interrupters is low, Vacuum interrupter scrapping and other problems, to achieve the effect of easy control, improve production yield, and reduce the amount of solder used

Inactive Publication Date: 2013-01-09

湖北大禹汉光真空电器有限公司

View PDF2 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The disadvantages of this structure are: the production efficiency of the vacuum interrupter is low, the positioning accuracy is poor and unreliable, the yield rate is low, and it is difficult to guarantee the quality

Therefore, the sealing ring of the traditional vacuum interrupter cannot adapt to the mass production of the vacuum interrupter and ensure the assembly accuracy requirements, and welding deviation often leads to the scrapping of the vacuum interrupter

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

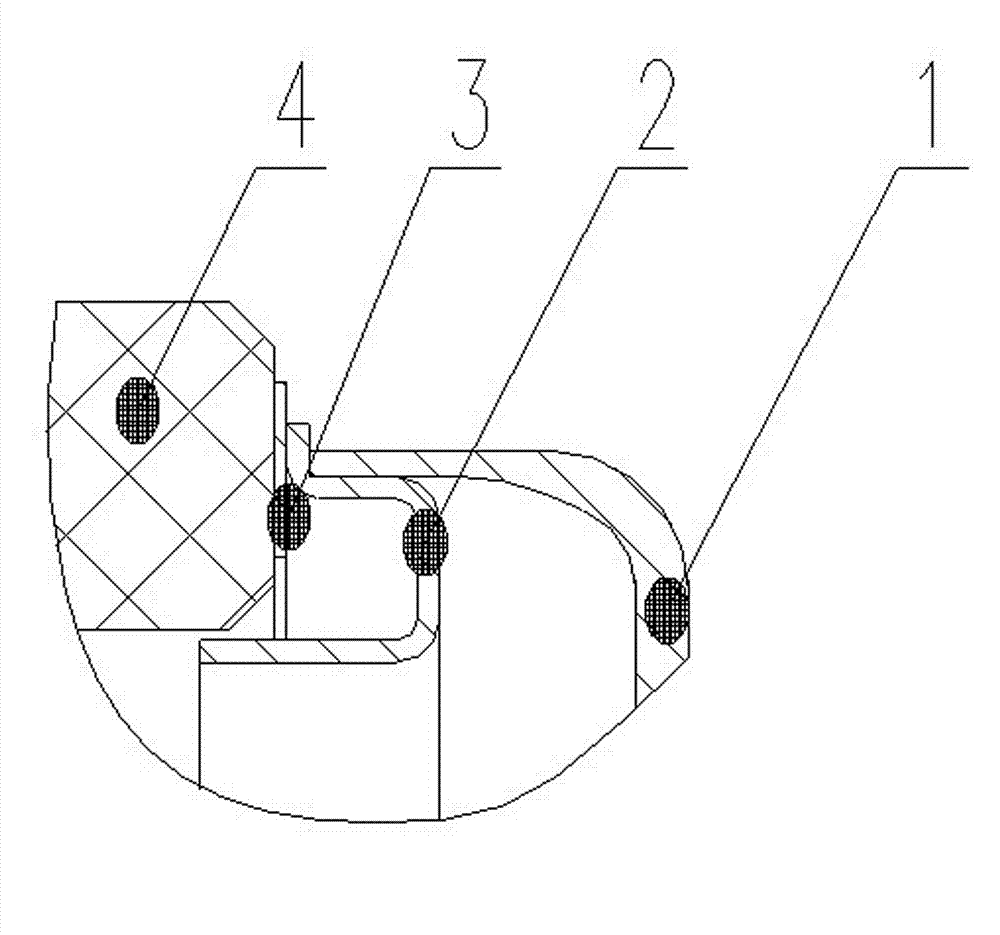

[0009] Such as figure 1 As shown, the static and dynamic end caps (1) and the sealing ring (2) are positioned through inner and outer steps, and the sealing ring (2) ensures the positioning between the solder sheet (3) and the porcelain cylinder (4).

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The patent of the invention relates to a vacuum arc extinguishing chamber positioning and sealing ring which is a brazing positioning for a vacuum arc extinguishing chamber, and mainly aims to solve the problems that conventional vacuum arc extinguishing chambers are low in production efficiency, poor and unreliable in positioning accuracy and low in yield, the quality of the vacuum arc extinguishing chambers are hard to ensure, and the requirement on batch production of vacuum arc extinguishing chambers can not be satisfied. The vacuum arc extinguishing chamber positioning and sealing ring comprises movable and stationary end caps, a sealing ring, a solder piece and a ceramic cylinder, and is mainly characterized in that the movable and stationary end caps and the sealing ring are positioned through internal and external steps; the sealing ring ensures the positioning between the ceramic cylinder and the solder piece; and in such a way, the positioning between the ceramic cylinder and the sealing ring, the movable and the stationary end caps. The vacuum arc extinguishing chamber positioning and sealing ring is simpler in operation, more accurate and reliable in positioning, higher in production efficiency, and the requirement on batch production of the vacuum arc extinguishing chambers is effectively satisfied.

Description

technical field [0001] The patent of the invention belongs to the technical structure design field of electric vacuum devices, and relates to a brazing positioning device for a vacuum interrupter. ring. Background technique [0002] As we all know, the production of vacuum interrupter is to use brazing process to weld the porcelain cylinders and dynamic and static end covers of different materials. Its structure is composed of dynamic and static end caps, sealing rings, solder sheets, and porcelain cylinders. The dynamic and static end caps and sealing rings are positioned through inner and outer steps, and the solder sheets can be fixed on the sealing rings through solder clips, and then ensured by the operator's observation. The positioning accuracy of the sealing ring and the ceramic cylinder. The disadvantages of this structure are: the production efficiency of the vacuum interrupter is low, the positioning accuracy is poor and unreliable, the yield rate is low, and it...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01H33/664

Inventor 王清华周倜

Owner 湖北大禹汉光真空电器有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com