Production management system and production management method, control program, readable storage medium

A production management system and production management technology, applied in the fields of production management systems and production management, control programs, and readable storage media, can solve problems such as insufficient invisibility, achieve pseudo-online management, realize operation error prevention, The effect of low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

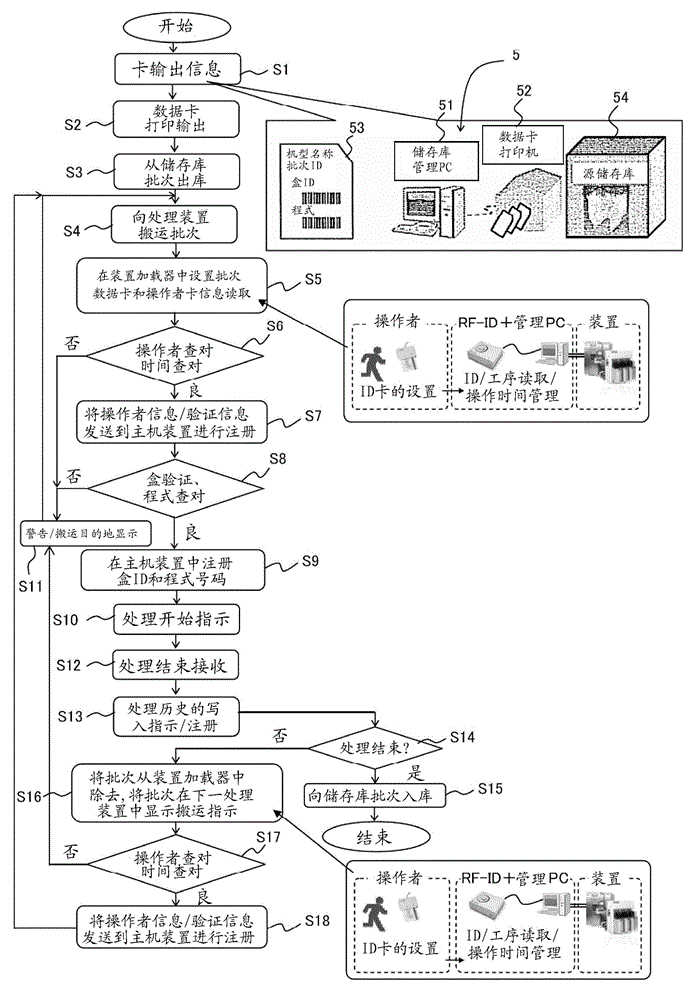

[0041] In the following, the production management system and the production management method using the same of the present invention, a control program for causing a computer to execute the processing procedures of the production management method, and a computer-readable storage medium storing the control program are described. implementation, while referring to the attached Figure 1 Explain in detail.

[0042] figure 1 It is a block diagram showing a configuration example of a main part of the production management system and its operation in the embodiment of the present invention.

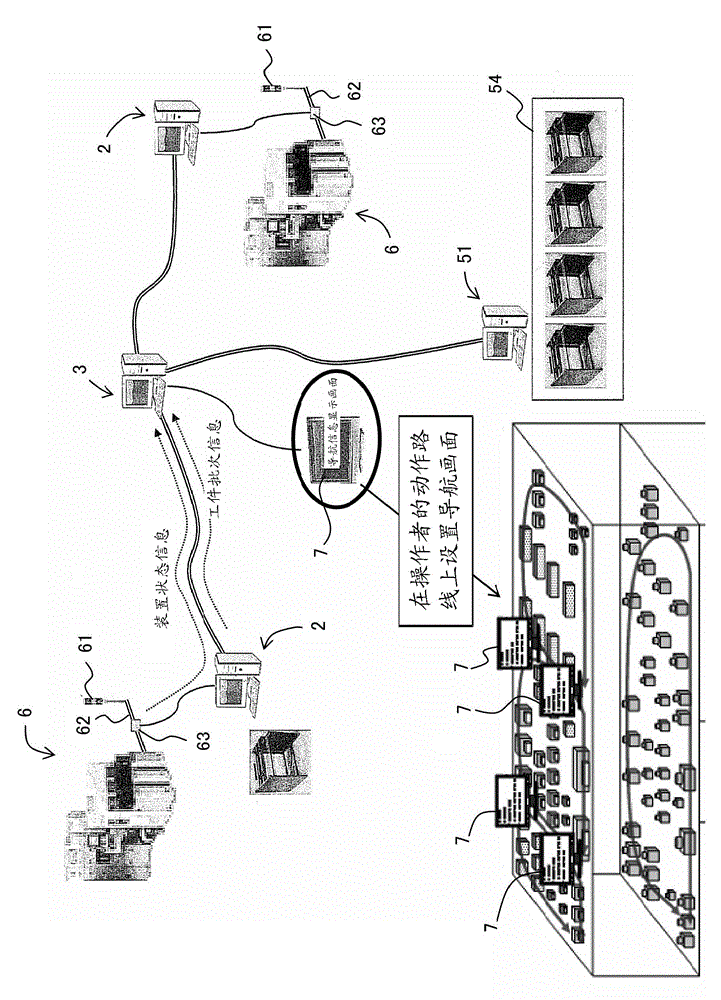

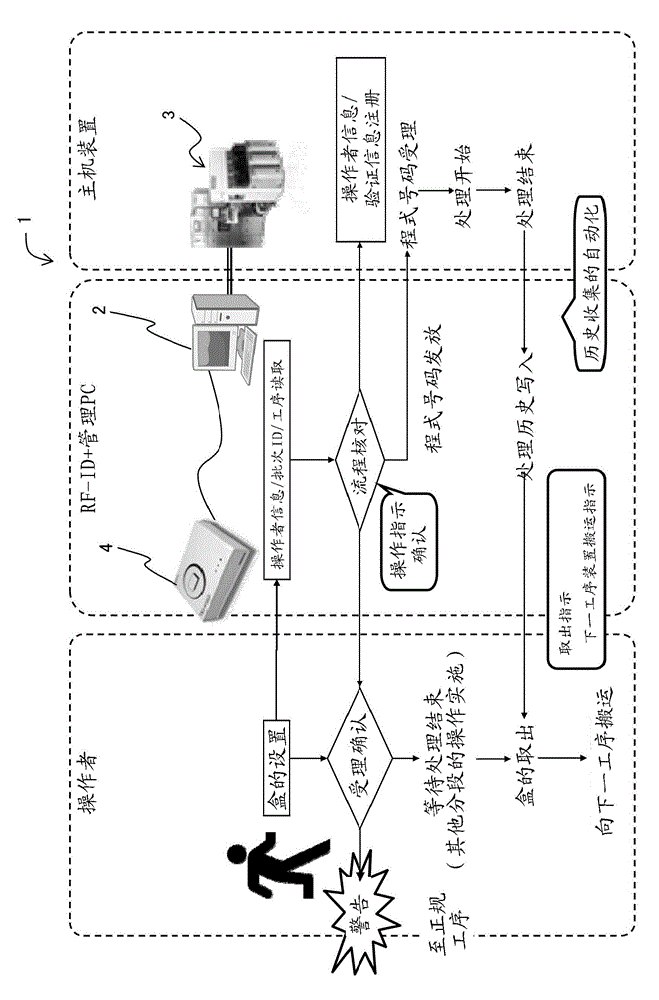

[0043] exist figure 1 Among them, the production management system 1 of the present embodiment has: each management personal computer 2, respectively attaches a unique ID to a plurality of processing devices including offline devices and a plurality of doors through which the operator enters and exits the room; The personal computers 2 carry out information exchange respectively; And the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com