Device and method for measuring parallel core foam flooding gas-phase shunt volume

A technology of gas phase split flow and foam generating device, which is applied in the direction of measuring device, volume measuring instrument/method, measuring capacity, etc., and can solve the problem that the volume cannot be directly measured

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

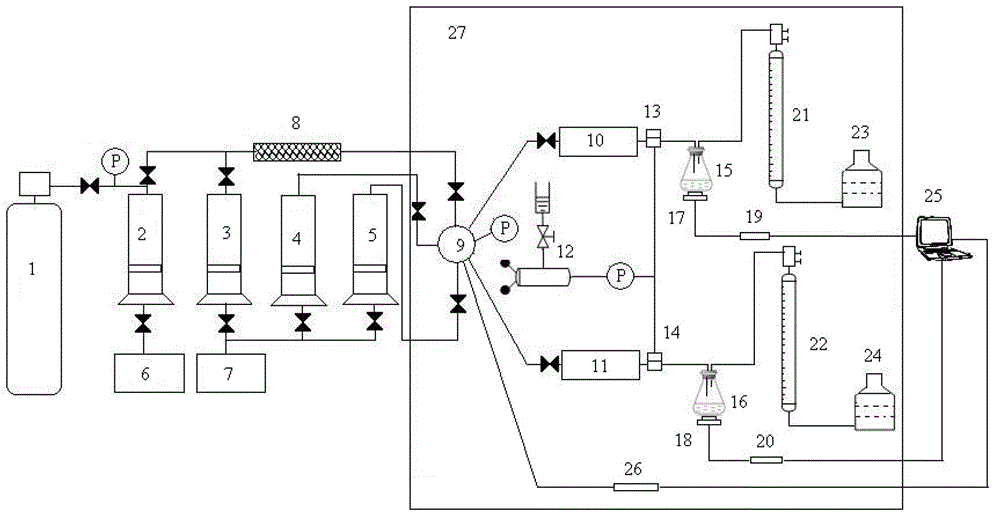

[0045] Such as figure 1 shown.

[0046] A device for measuring the fractional flow rate of the foam-driven gas phase in parallel rock cores, comprising a foam generating device, an intermediate container 4 for holding formation water, an intermediate container 5 for holding crude oil, a constant temperature box 27, a core tube 10, a core tube 11 and a data acquisition system The core tube 10 and the core tube 11 are installed in parallel in the thermostat 27; the foam generating device, the intermediate container 4 for holding formation water, and the intermediate container 5 for holding crude oil pass through the six-way valve respectively 9 is connected with the entrance of rock core pipe 10 and rock core pipe 11; Described data acquisition system comprises the pressure sensor 26 that links to each other with computer 25, load cell 19 and load cell 20, and described pressure sensor 26 is installed in six-way The valve 9 is the core pipe 10 and the inlet end of the core pipe...

Embodiment 2

[0049] A method for measuring the fractional flow rate of the foam-driven gas phase of parallel cores by using the above-mentioned device, comprising the following steps:

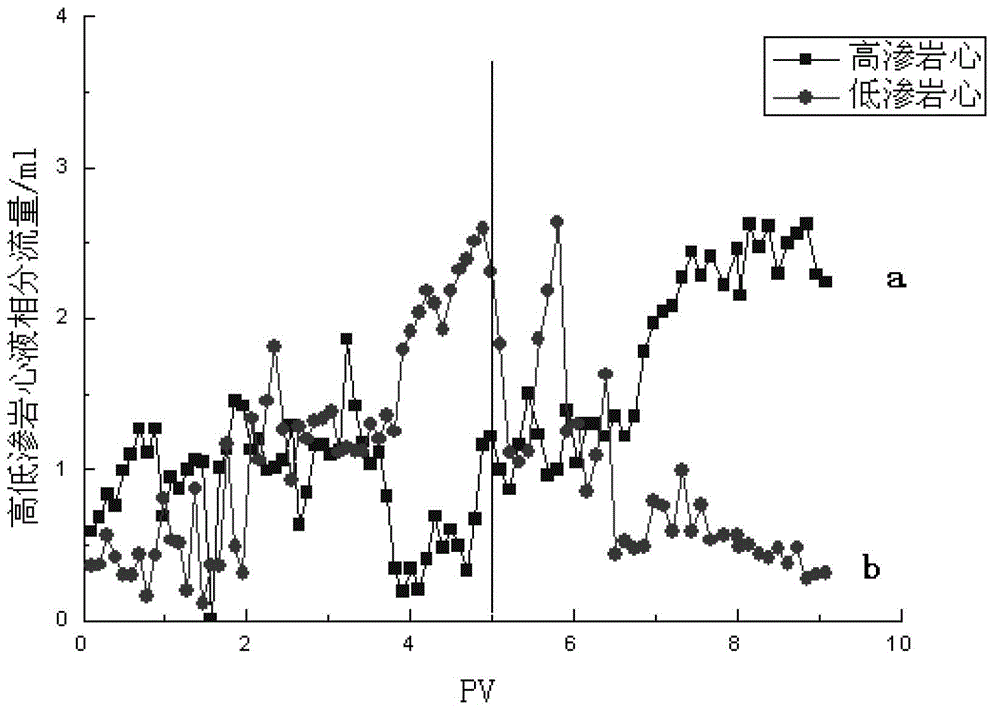

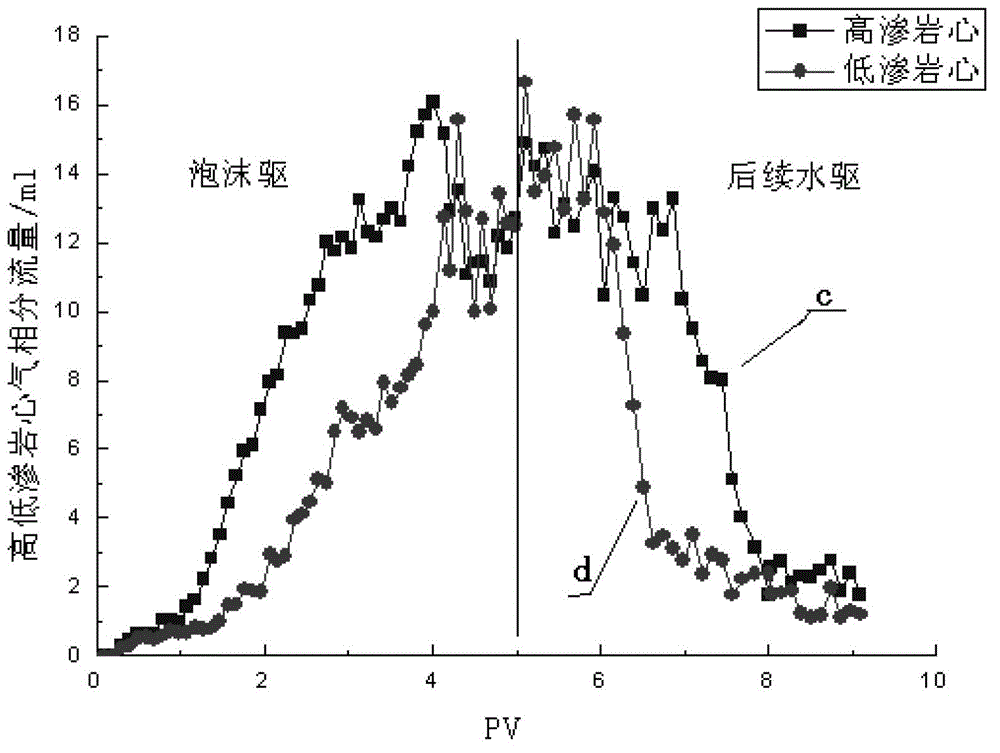

[0050] The required conditions of the method for measuring the gas phase saturation of the parallel core foam flooding are: the density of the foaming agent solution is equal to the density of the formation water; the partial flow rate of the gas phase at the outlet end of the parallel core is the flow rate under the standard atmospheric pressure of 0.1 MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com