Easily assembled capillary tube

A technology of capillary and body, applied in the field of easy-to-install capillary, can solve the problems of port blockage, low success rate, cumbersome assembly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

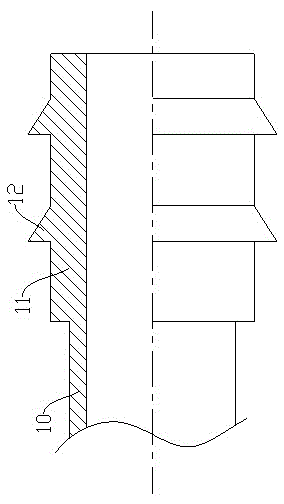

[0012] Examples, see figure 1 As shown: an easy-to-install capillary tube, including a tubular body 10 , and an anti-falling step 12 is provided on the outer surface of the port portion of the body 10 . Of course, the anti-off step 12 can be multi-turn. In this way, it is possible to avoid the necessary welding connection during assembly, so that the assembly is simple and the success rate is high.

[0013] Optimally, the anti-off step 12 is in the shape of inverted teeth. The so-called inverted tooth shape means that the cross section of the anti-escape step 12 can be a right triangle with the vertical side inside the body 10 . In this way, smooth assembly is beneficial, and after the assembly is completed, it is not easy to disengage between the capillary tubes connected together or between the capillary tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com