Fireproof hydraulic control device

A control device and hydraulic technology, applied in the direction of valve device, valve operation/release device, functional valve type, etc., can solve the problems of aggravating accidents, easy to generate electric sparks, hidden safety hazards, etc. Force limit, stable and reliable installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

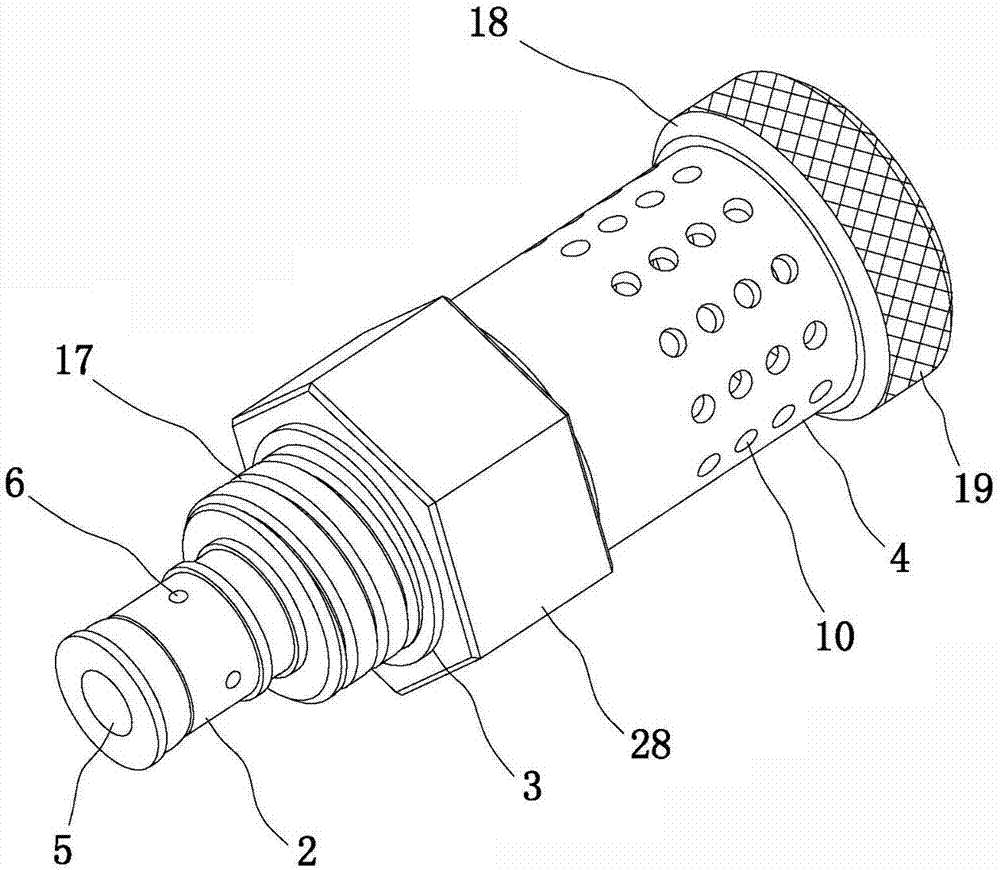

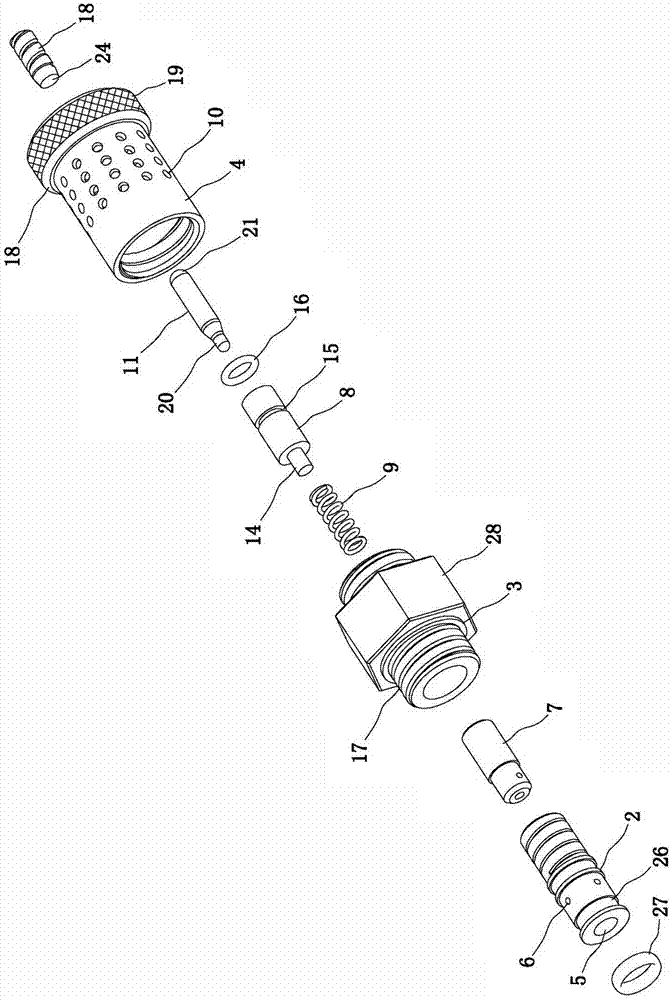

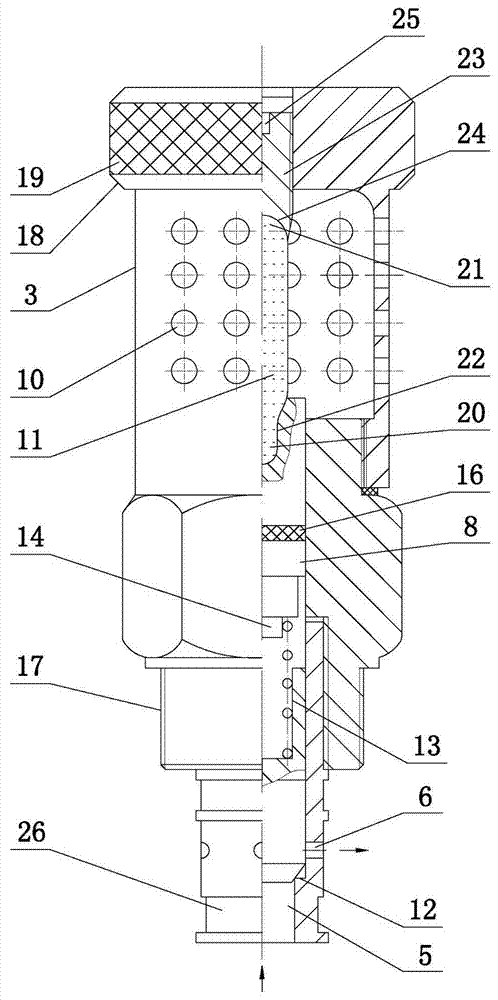

[0021] The present invention will be further described below in conjunction with accompanying drawing:

[0022] Referring to the accompanying drawings: the fire prevention hydraulic control device in this embodiment includes a hollow cylinder 2 connected to the oil circuit 1 of the hydraulic valve. There is a cover 4; the hollow cylinder 2 is provided with a liquid inlet 5 and a liquid outlet 6, and the inner cavity of the hollow cylinder 2 is provided with a spool 7 for closing the liquid inlet 5 and the liquid outlet 6; the mounting seat 3 There is a movable guide rod 8 inside, and a spring 9 is supported between the movable guide rod 8 and the valve core 7; a group of through holes 10 are arranged on the wall of the casing 4, and a temperature-sensitive glass ball 11 is arranged inside the casing 4, and the sensor One end of the warm glass ball 11 is against the movable guide rod 8, and the other end is against the inner end surface of the casing 4.

[0023] The inner wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com