Improved method for converting plant pollen tube

A plant pollen and plant technology, applied in the field of improved plant pollen tube transformation, can solve the problems of low transformation efficiency, easy degradation of exogenous plasmid DNA and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

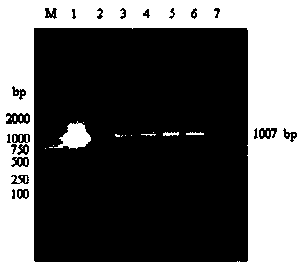

[0031] Example 1 Extraction of Plant Expression Vector pCAMBIA1301 Plasmid DNA

[0032] The plasmid DNA was extracted from Escherichia coli containing the plant expression vector pCAMBIA1301 according to the conventional plasmid DNA extraction method-alkaline lysis method.

Embodiment 2

[0033] Embodiment 2 Preparation of Aluminum Hydroxide Sol Protective Agent

[0034] (1) Add 2-4mL 1% aluminum chloride solution to a glass test tube, then add 0.05-2 mL 10% ammonia water to form a precipitate;

[0035] (2) Discard the supernatant, wash the precipitate with distilled water for 3-5 times, remove the water by decantation, and separate the lotion from the precipitate by filtration for the last time;

[0036] (3) Transfer the precipitate into a 150 mL beaker, add 20-80 mL of distilled water, stir and heat to boil. During this period, add 0.1-0.2 mL 0.1 mol / L HCl solution and keep stirring to obtain aluminum hydroxide sol;

[0037] (4) Take a little aluminum hydroxide sol and resuspend the pCAMBIA1301 plasmid DNA precipitate extracted in Example 1, and the obtained mixture is aluminum hydroxide sol-pCAMBIA1301, and the concentration of the plasmid DNA of pCAMBIA1301 is 0.8-1.2 μg / μL.

Embodiment 3

[0038] Embodiment 3 Preparation of calcium phosphate protective agent

[0039] (1) Resuspend the plasmid DNA precipitate of pCAMBI1301 extracted in Example 1 with 5-15 μL of sterilized distilled water to make the concentration 1 μg / μL, then add 50-60 μL of 2 mol / L CaCl2 solution and mix well. Occasionally, a small amount of turbid substance will appear.

[0040] (2) Centrifuge at 12000 r / min for 10 min, take out the supernatant, and add it to 400-450 μL sterilized distilled water, which is called pCAMBIA1301-CaCl2 solution.

[0041] (3) Take a 2 mL sterilized centrifuge tube, add 500 μL 2×HEPES buffer solution (pH6.95-7.05) into it, and add pCAMBIA1301-CaCl2 solution drop by drop into the HEPES buffer solution by blowing air.

[0042] (4) Place the test tube in a 37°C water bath and incubate for 3-5 minutes, milky white turbidity can be seen.

[0043] (5) Centrifuge at 10000 r / min for 3 min, discard the supernatant. The resulting mixture was calcium phosphate-pCAMBIA1301, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com