Movable guide rod type reciprocating wing lifting force generation device

A technology for generating devices and guide rods, which can be used in helicopters, motor vehicles, transportation and packaging, etc., and can solve problems such as inability to take off and land vertically, low maneuverability and safety in operation, and complex structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

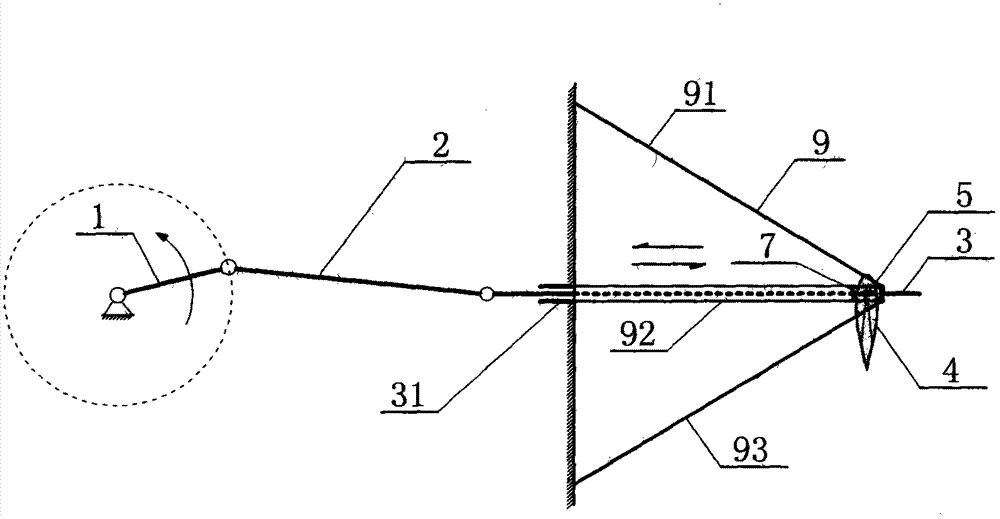

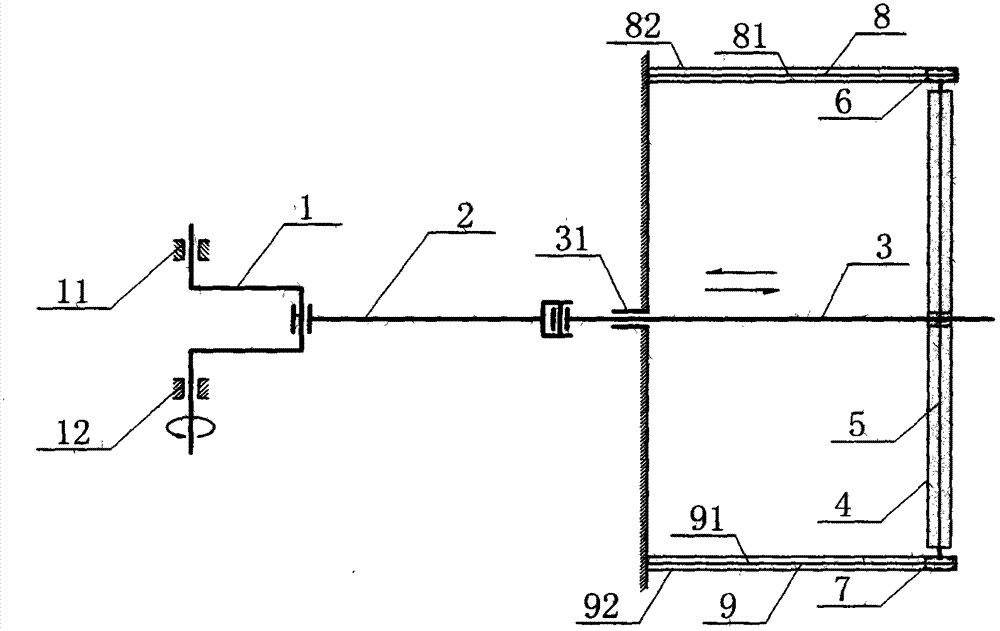

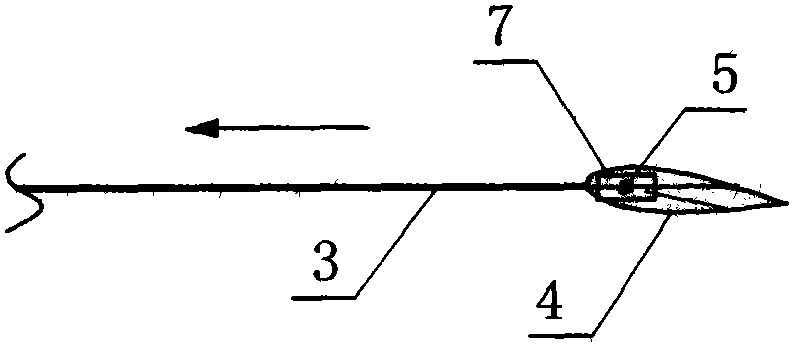

[0018] Provide the implementation example of the present invention below, and in conjunction with appendix Figure 1-7 To illustrate.

[0019] As shown in the figure, a moving guide rod type reciprocating wing lift generating device of the present invention includes a crankshaft 1, a crankshaft front bearing 11, a crankshaft rear bearing 12, a connecting rod 2, a moving guide rod 3, a guide rod linear bearing 31, and a reciprocating wing 4 and the reciprocating wing drive shaft 5; the crankshaft 1 is installed on the fuselage through the crankshaft front bearing 11 and the crankshaft rear bearing 12, the crankshaft front bearing 11 and the crankshaft rear bearing 12 are arranged on the same horizontal plane, and the left end of the connecting rod 2 is connected with the crankshaft 1 , the right end of the connecting rod 2 is connected with the left end of the moving guide rod 3, the moving guide rod 3 passes through the guide rod linear bearing 31 fixedly installed on the side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com