Method for manufacturing customized shoe pads

A manufacturing method and technology of insoles, which are applied to footwear, other household appliances, household appliances, etc., can solve the problems of time-consuming, complicated production and sampling process, and high cost of customized insoles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

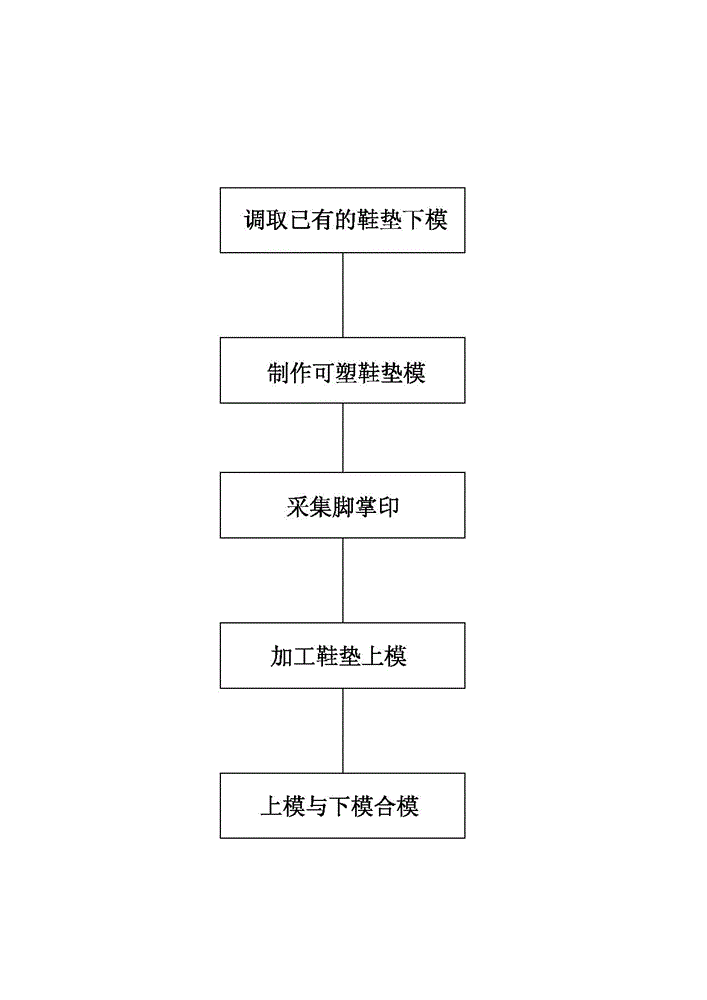

[0028] Please refer to Figure 1 to Figure 8 Shown, it has shown the specific production process of the preferred embodiment of the present invention, including the following steps:

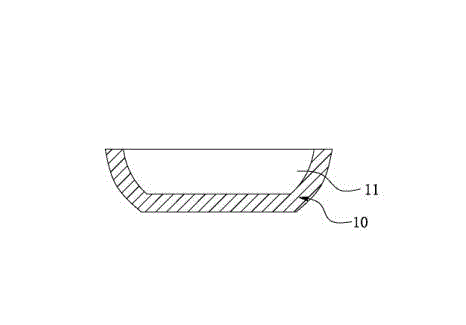

[0029] (1) Call the existing lower mold for insoles: such as figure 2 As shown, the customer has purchased the shoes with pre-stored files, that is, the lower insole mold 10 of the original insole, and the lower insole mold 10 is taken out for later use, because the internal and external shapes and sizes of the customer's shoes are recorded in the pre-stored files. data, so this data can be used to adjust the customized insole according to the customer’s response or the judgment of medical theory. The insole made with the original insole lower mold 10 has been confirmed to make the insole match the customer’s existing shoes, solving the problem of waiting to be made Accurate positioning of insoles, shoe cavities, and midsoles.

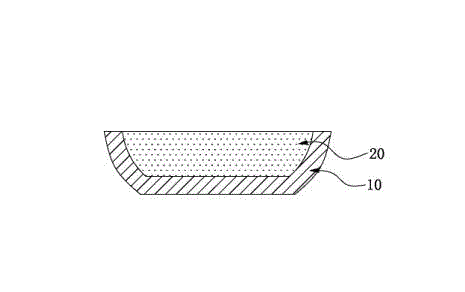

[0030] (2) Making plastic insole molds: such as image 3 and F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com