Automatic plasma welding device for welding of stainless hollow cutter bar

A plasma welding and automatic welding technology, used in plasma welding equipment, auxiliary devices, welding equipment, etc., can solve the problems of unsuitable stainless steel hollow shank welding, unable to use stainless steel hollow shank, unstable welding seam of the machine, etc., to achieve savings The effect of human capital, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

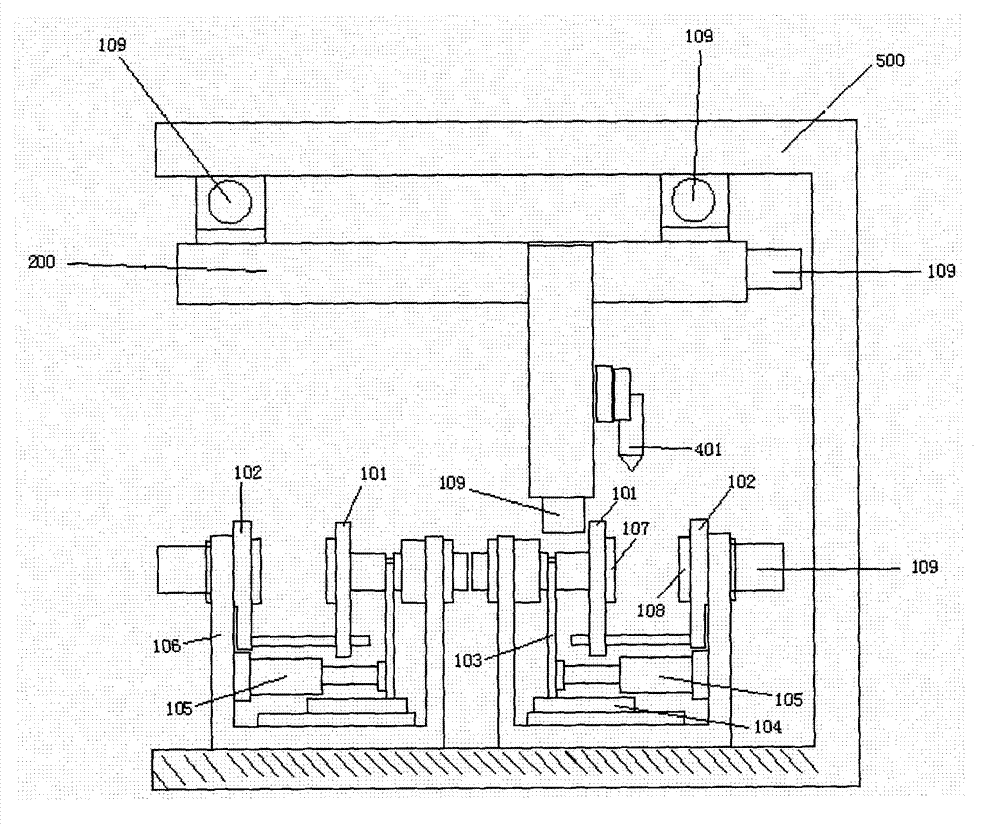

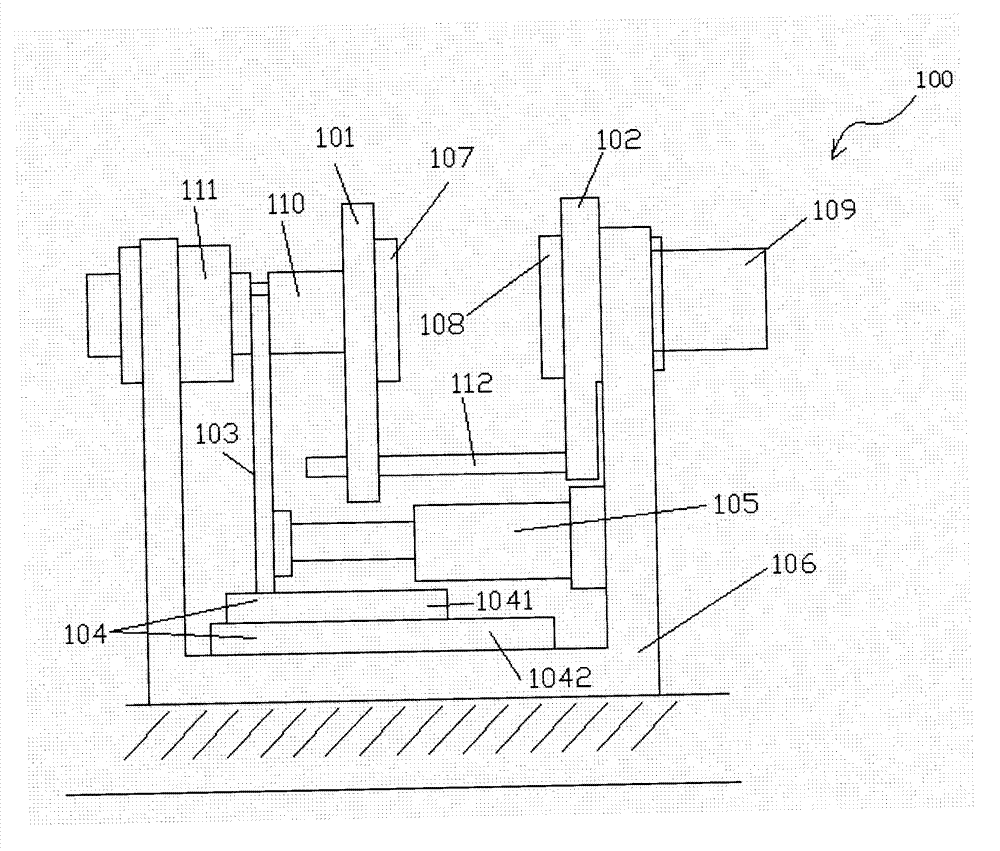

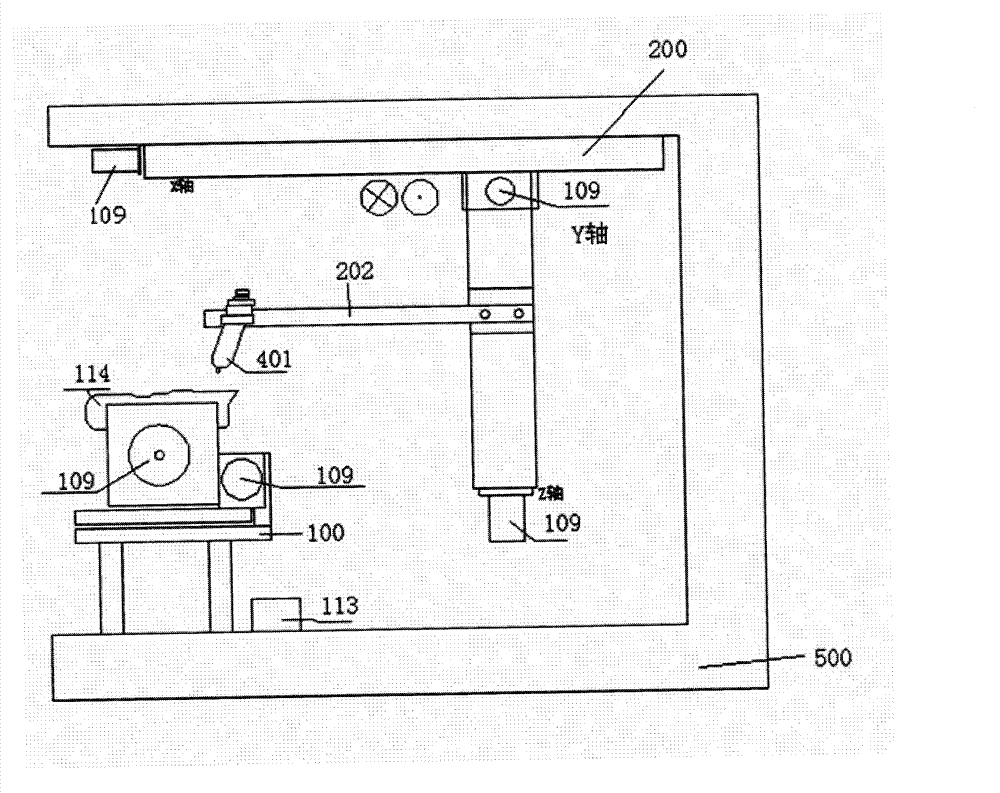

[0022] refer to figure 1 According to one embodiment of the present invention, a plasma automatic welding device for welding stainless steel hollow handles is provided. The plasma automatic welding device is installed on a support frame 500 of a steel structure, including a handle clamping mechanism 100, a handle The rotating mechanism 300, the plasma torch traveling mechanism 200 and the plasma welding mechanism 400 (not shown); wherein, the knife handle clamping mechanism 100 is used to clamp and fix the two-lobed knife handle shell; the knife handle rotating mechanism 300 is installed in the tool handle clamping mechanism 100, and is used for rotary welding when welding the tool handle; the plasma torch traveling mechanism 200 is used for welding when the plasma beam follows the weld seam for three-dimensional trajectory walking w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com