A kind of shoe sole with elastic breathable function and its production process

A functional and elastic technology, which is applied in the field of elastic and breathable soles and its production technology, can solve the problems of not easy to discharge sweat in time, unsatisfactory sole design, and reduced elasticity, and achieve novel structural design, excellent elasticity, and excellent elastic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

[0026] Take the sole of a sneaker, for example.

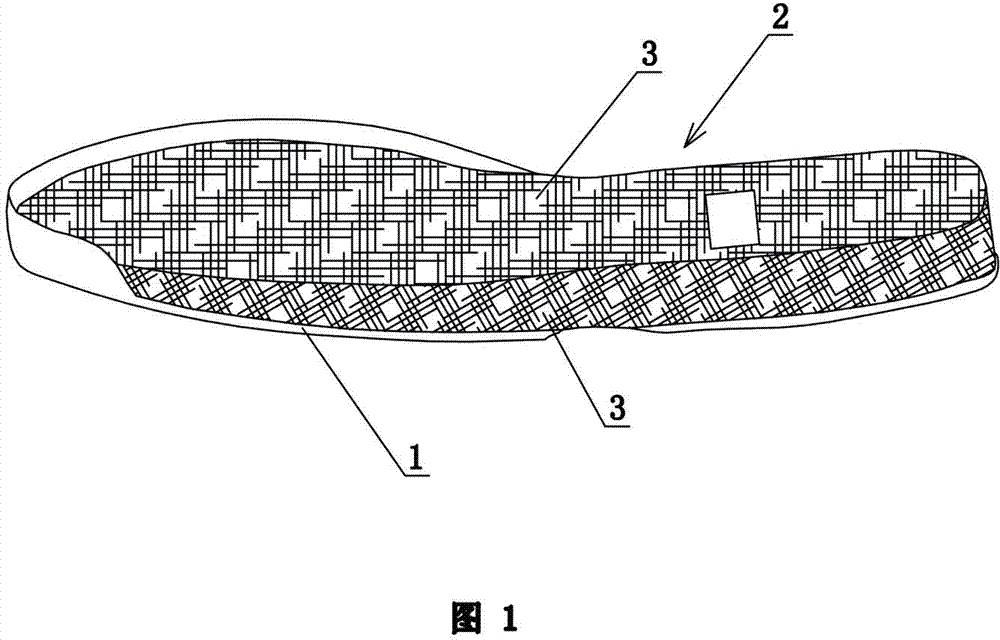

[0027] refer to figure 1 . A shoe sole with elastic and breathable functions, including a outsole 1 and a midsole 2 connected with the outsole 1 and formed by interweaving and pressing elastic threads. A certain gap 3 is formed between the elastic threads, and the midsole 2 and the outsole 1 are arranged up and down . The outsole 1 is a rubber outsole, the elastic thread is a TPU thread, and the TPU thread is made of TPU material.

[0028] TPU is the English abbreviation of "Thermoplastic polyurethane". Its Chinese name is thermoplastic polyurethane elastomer. The TPU material has excellent tensile strength, compressibility, impact resistance, resilience and other properties.

[0029] refer to figure 1 . The midsole 2 formed by interweaving and pressing the above TPU threads has excellent elastic...

Embodiment 2

[0034] Take the sole of a sneaker, for example.

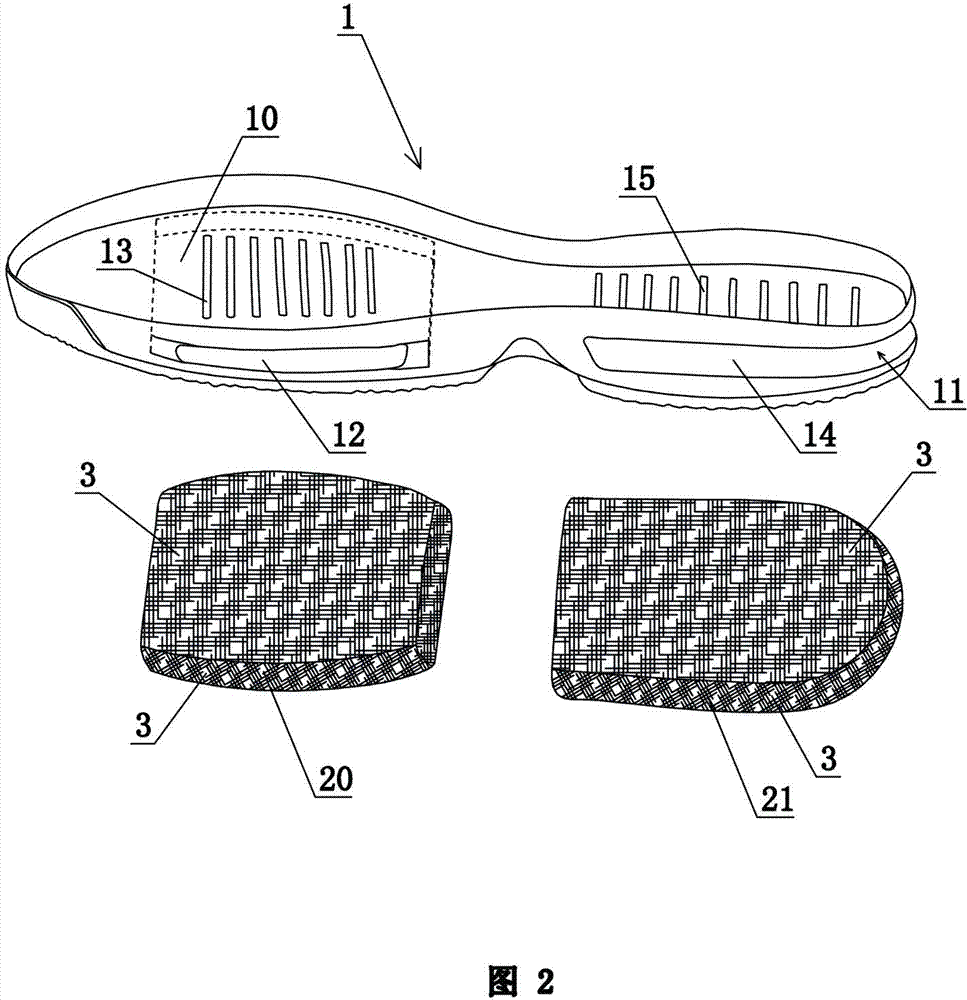

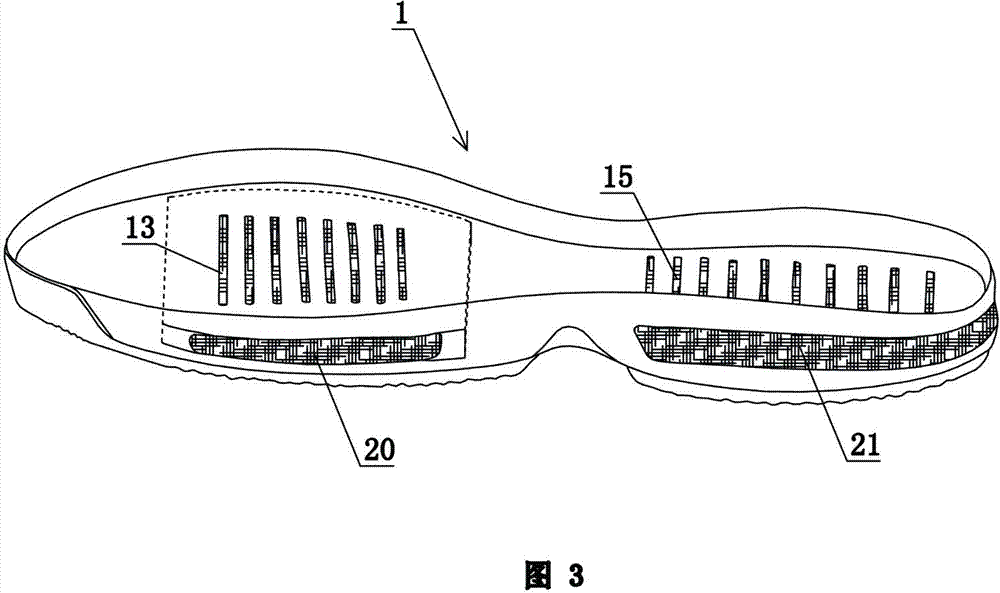

[0035] refer to figure 2 and image 3 . A shoe sole with elastic and breathable functions, comprising a large bottom 1 and a midsole connected with the large bottom 1 and formed by interweaving and pressing elastic threads. The elastic threads are metal threads, and a certain gap 3 is formed between the metal threads. The large bottom 1 There are forefoot accommodation chambers 10 and heel accommodation chambers 11 arranged front and back, and the left and right side walls of the front palm of the outsole are provided with forefoot bar-shaped openings 12 communicating with the front accommodation chamber 10. The outsole The top surface of the front palm part is provided with the front palm exhaust port 13 communicating with the front accommodation chamber 10, and the heel bar opening 14 communicating with the heel accommodation chamber 11 is provided on the heel part side wall of the big bottom. The top surface of the u...

Embodiment 3

[0040] The implementation of this example and Example 1 is basically the same, the difference is that the production process of the sole is different. The production process of the sole includes: 1) interweaving a plurality of TPU silk threads together to form a fluffy composition ; 2) Then compress the composition to form a half-finished midsole plate through a plate pressing machine; 3) Place the midsole plate on the cutting table, and cut the midsole plate with a cutting knife to cut out the midsole; 4 ) and then connect the midsole to the outsole by gluing, that is, the sole is completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com