Method for producing anti-pilling and antistatic cashmere sweaters

A production method and antistatic technology, applied in the field of cashmere sweaters, can solve the problems affecting the appearance quality and service life of cashmere sweaters, poor fiber cohesion, and poor strength, and achieve excellent antistatic effect, enhanced binding force, and firm combination. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The production method of anti-pilling and antistatic cashmere sweater comprises the steps:

[0017] The cashmere and milk protein fibers are blended according to the mass ratio of 5:1. In the twisting step, the single yarn twist of the cashmere blended yarn is 520 twists / m, and the twist direction is Z twist; in the two-for-one twisting step, the cashmere blended yarn is made Line ply twist: 360 twist / m, twist direction is S twist; the twist ratio of ply to single yarn is 0.32; then the anti-pilling cashmere sweater is obtained through the steps of knitting, clothing, and antistatic finishing;

[0018] The fineness of the cashmere is 18 μm, and the length is 22mm;

[0019] The milk protein fiber has a fineness of 25 μm and a length of 33 mm;

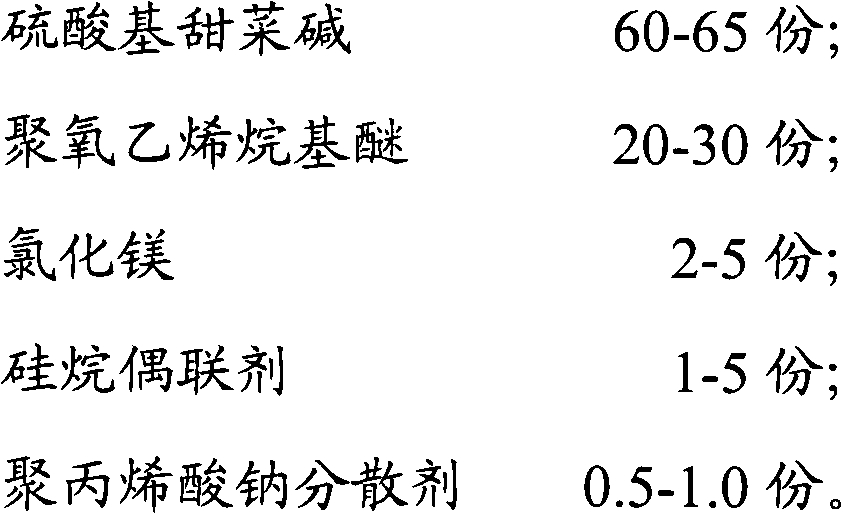

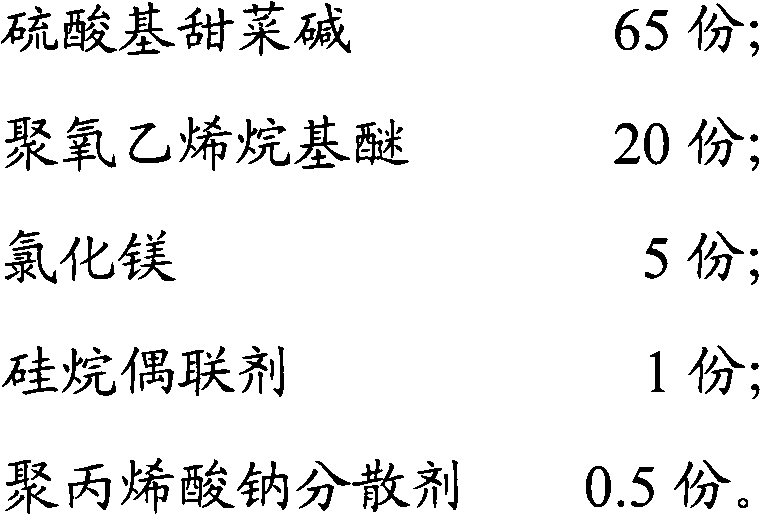

[0020] The antistatic finishing step includes padding treatment in the immersion solution containing antistatic finishing agent, the pressure is 2.5kg / cm 2 , with a liquid-carrying rate of 80%; drying treatment, and then constan...

Embodiment 2

[0025] The production method of anti-pilling and antistatic cashmere sweater comprises the steps:

[0026] The cashmere and milk protein fibers are blended according to the mass ratio of 5:2. In the twisting step, the single yarn twist of the cashmere blended yarn is 550 twists / m, and the twist direction is Z twist; in the two-for-one twisting step, the cashmere blended yarn is made Line ply twist: 380 twist / m, twist direction is S twist; the twist ratio of ply and single yarn is 0.47; then the anti-pilling cashmere sweater is obtained through the steps of knitting, garment and antistatic finishing;

[0027] The fineness of the cashmere is 22 μm, and the length is 25mm;

[0028] The milk protein fiber has a fineness of 32 μm and a length of 38 mm;

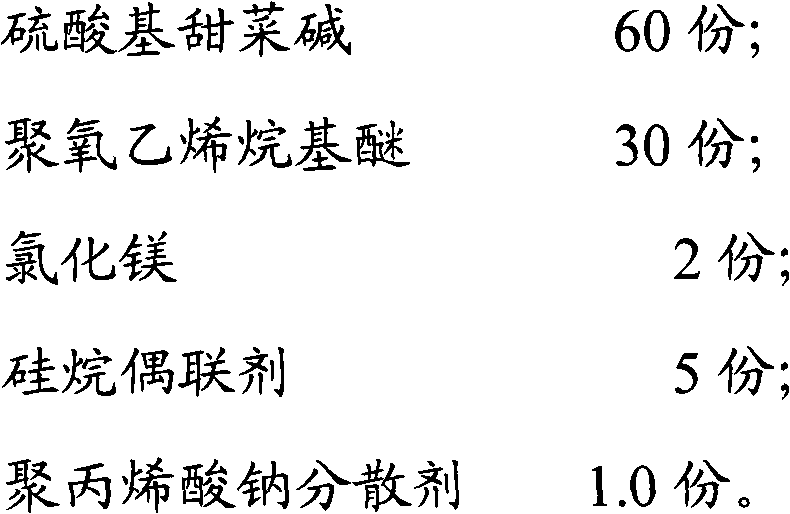

[0029] The antistatic finishing step includes padding treatment in the immersion solution containing antistatic finishing agent, the pressure is 2kg / cm 2 , liquid-carrying rate of 75%; drying treatment, and then constant temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com