Method of manufacturing cushion for front passenger seat air bag device

A technology of airbag device and passenger seat, which is applied in the field of cushioning parts manufacturing, which can solve the problems of gas leakage, failure to form protrusions, breakage, etc., and achieve the effect of small capacity and stable expansion and deployment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Before describing the manufacturing method of the present invention, first, an airbag device for a passenger's seat provided with a cushioning material that can be manufactured by applying the sewing method of the present invention will be described, that is, reducing the capacity of the cushioning material while simultaneously An airbag device for a passenger's seat that stabilizes the behavior during inflation and deployment and has sufficient shock absorption performance will be described.

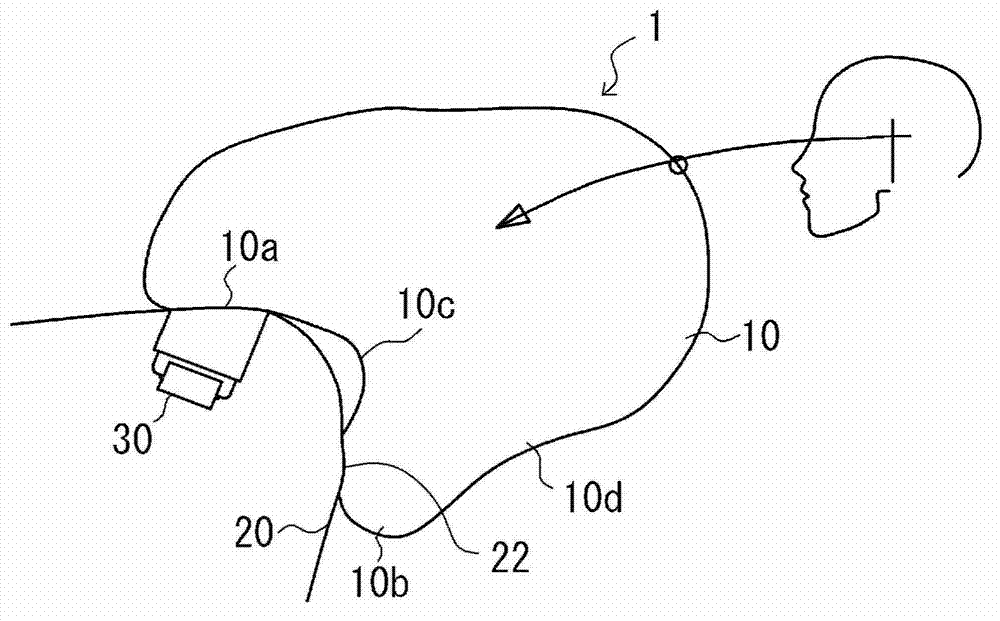

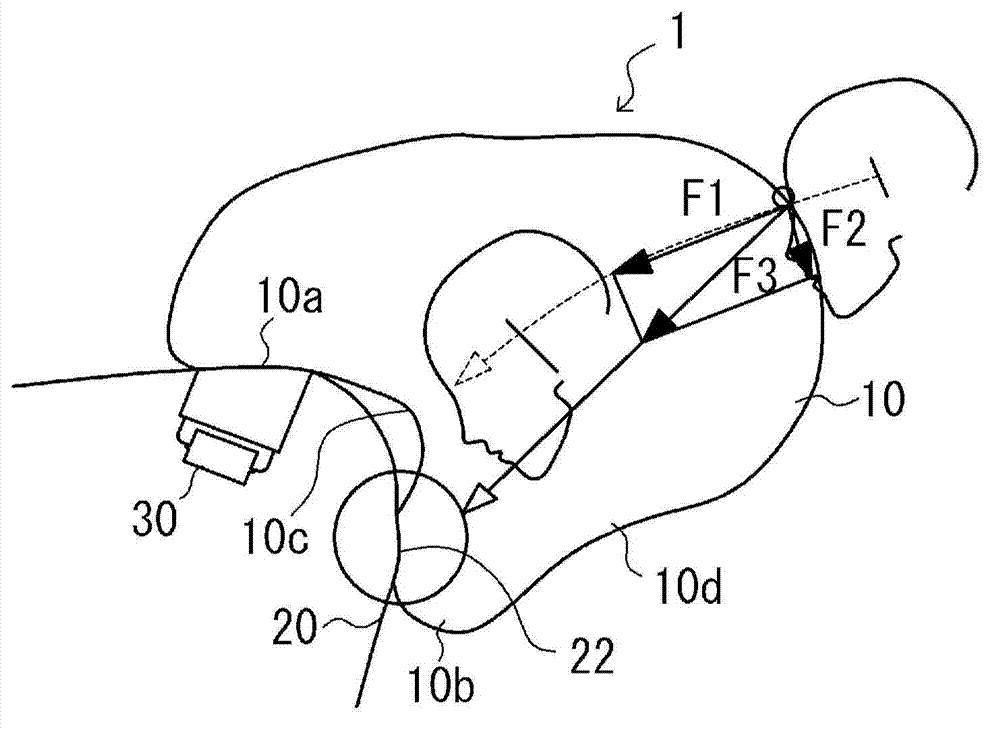

[0037] figure 1 It is a perspective view at the time of inflation of the shock absorber 10 of the airbag device for a passenger's seat described above.

[0038] figure 2 It is a side view of the above-mentioned cushioning material 10 when inflated, and shows the state before a passenger enters.

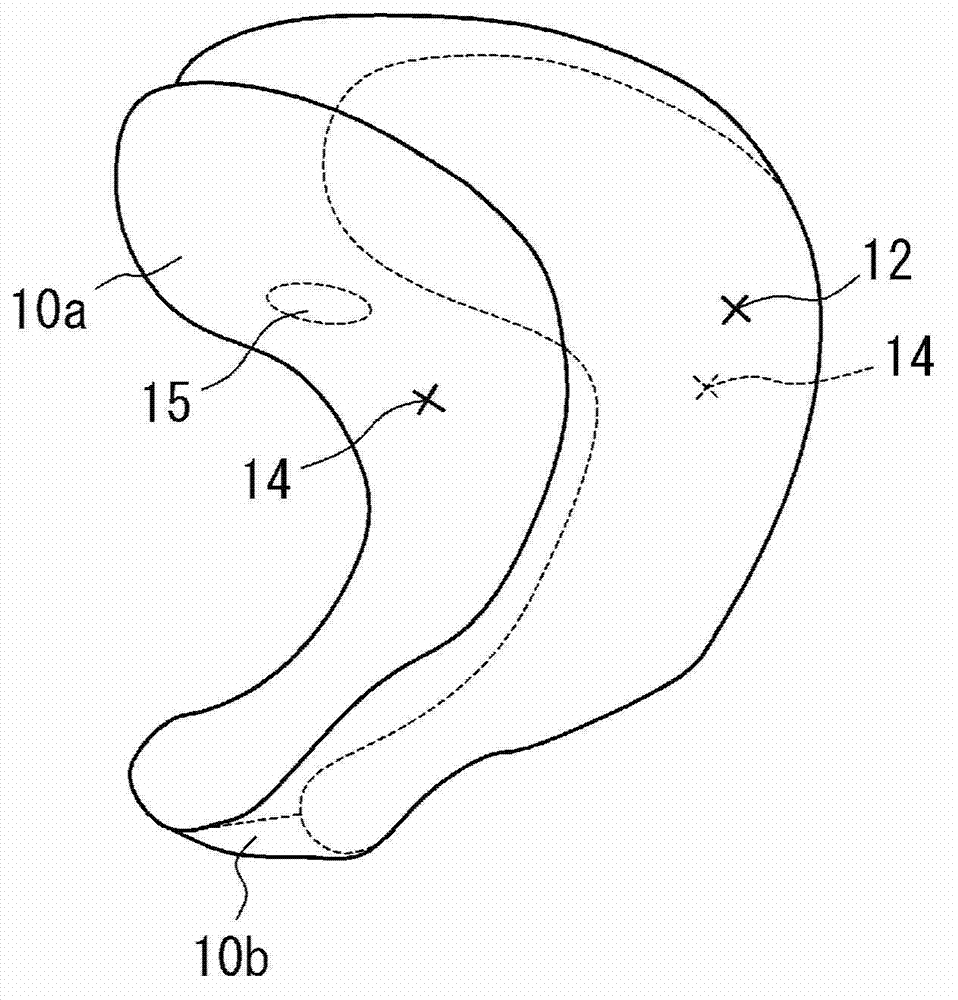

[0039]The cushioning member 10 of the airbag device 1 for the passenger's seat is composed of three parts, namely a main panel 12 and side panels 14 , and is integrally formed by att...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com