Automatic soft rock disintegration screening instrument and testing method thereof

An automatic sieving and soft rock technology, which is applied in the direction of removing certain components, weighing, and preparing samples for testing, can solve the problem of inability to make timely judgments when the disintegration basically stops, the overall stability of the roadbed is reduced, and the Problems such as large loss of sample mass, to achieve the effect of small error, improved efficiency, and reasonable device structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation of a new type of practical carbonaceous soft rock disintegration automatic sieving instrument will be described in detail below in conjunction with the accompanying drawings.

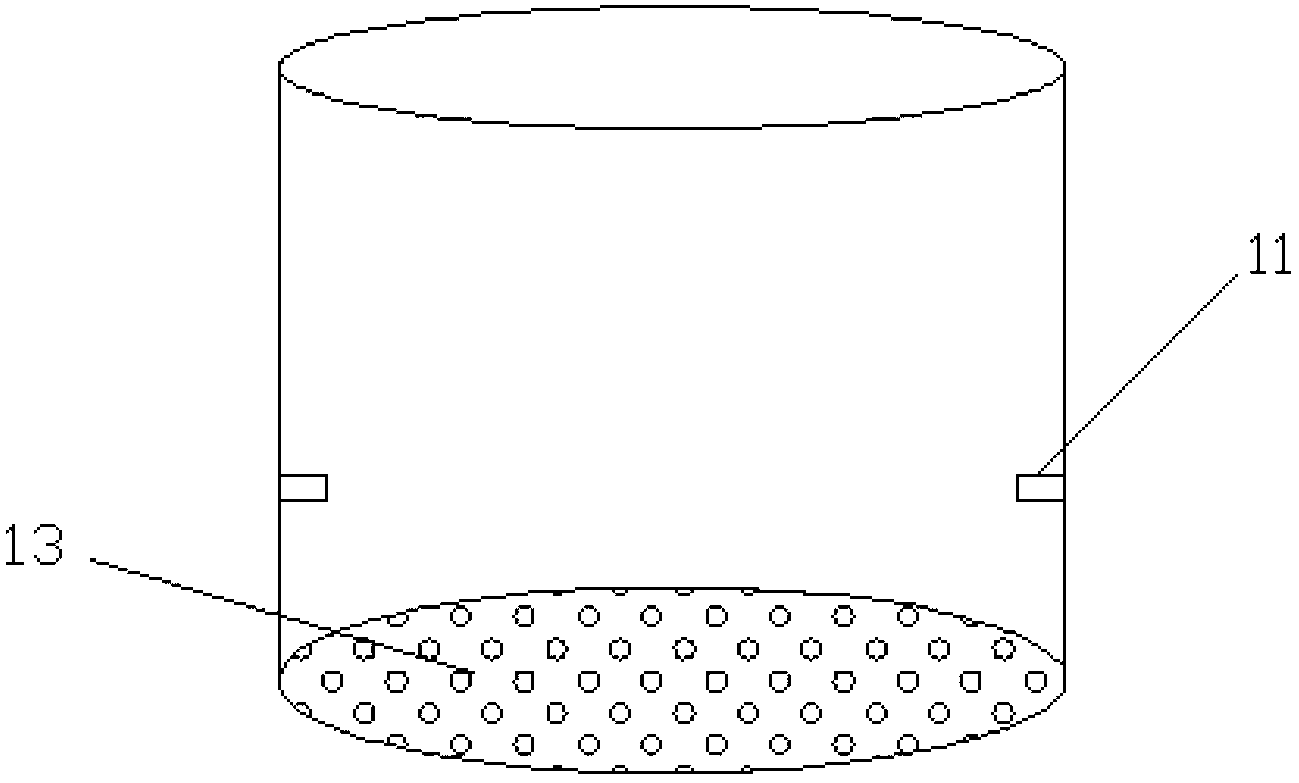

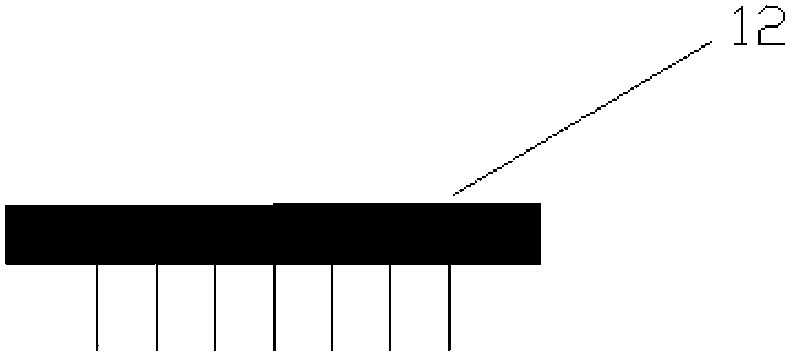

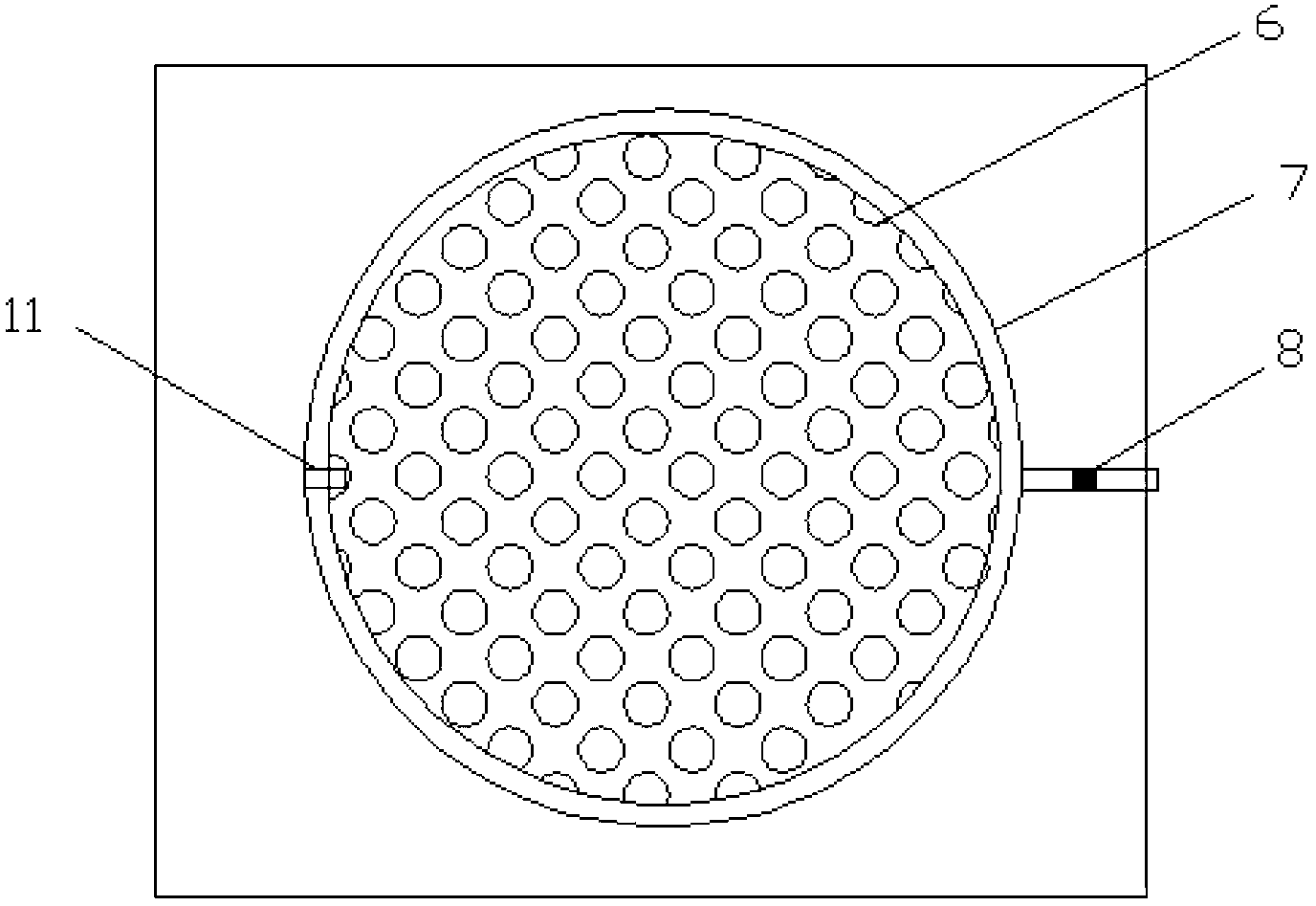

[0026] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a transparent outer cylinder 7 is provided on the frequency-adjustable vibrating table 9, a water inlet pipe 10 is provided at the height of the transparent outer cylinder 7, and a water outlet pipe 8 is provided at the low position of the transparent outer cylinder 7, and the transparent outer cylinder 7 The first transparent inner cylinder 1, the second transparent inner cylinder 2, the third transparent inner cylinder 3, the fourth transparent inner cylinder 4, the fifth transparent inner cylinder 5 and the sixth transparent inner cylinder 6 are placed in order from top to bottom. The first transparent inner cylinder 1, the second transparent inner cylinder 2, the third transparent inner cylin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com