COB (chip on board)-LED module and production process

A COB-LED and module technology, which is applied in the field of COB-LED modules and production technology, can solve problems such as maintenance, inconvenient installation, complex structure, etc., to achieve convenient installation and operation, reduce invisible damage, and reduce defective rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with accompanying drawing:

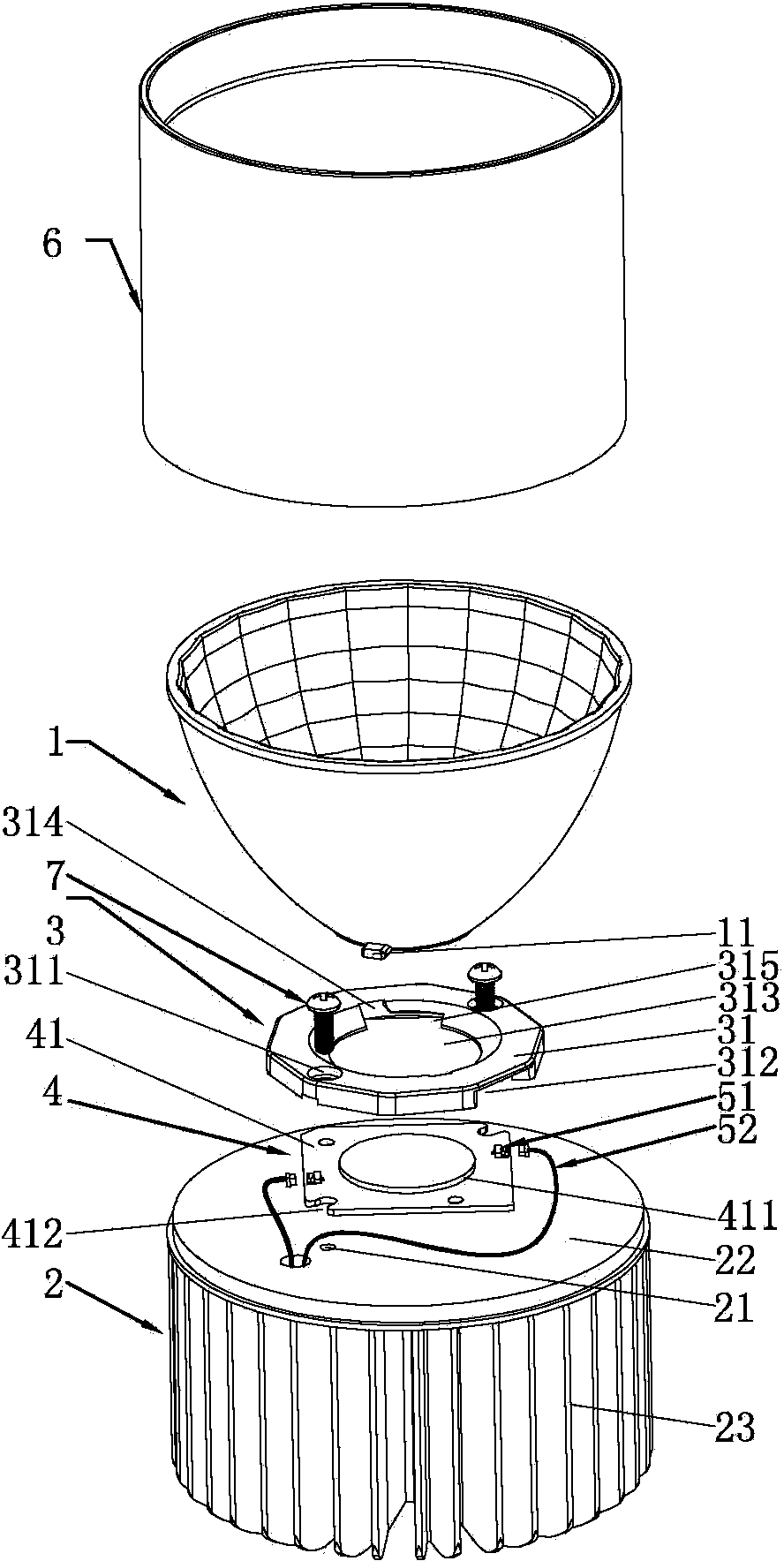

[0032] see figure 1 As shown, the COB-LED module is composed of an electrical interface bracket 3 between the conical reflector 1 and the radiator 2 and a COB-LED module 4 fixed by the electrical interface bracket 3 .

[0033] In this embodiment, the electrical interface bracket 3 is symmetrically opened by the ring frame 31, the screw holes 311 symmetrically opened on the ring frame 31, and the bottom of the ring frame perpendicular to the ring frame screw holes 311 for the COB-LED module 4 to pass through. The groove 312 of the ring frame inner hole 313 is composed of a slot 314 recessed radially symmetrically along the hole and a positioning groove 315 communicated with the slot 314 along one side of the slot 314 in a ring shape.

[0034] In this embodiment, the edges of the bottom opening of the conical reflective cup 1 protrude outward symmetrically along th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com