Locking nut

A technology for locking nuts and nut bodies, which is applied to nuts, threaded fasteners, connecting components, etc., can solve the problems of inconvenient disassembly and assembly of pipe wrenches, large physical effort, and heavy pipe wrenches.

Inactive Publication Date: 2013-01-02

WUXI YAQING MACHINERY

View PDF9 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] In some equipment and facilities, it is often necessary to fasten the parts. Generally speaking, the friction between the nut and the bolt is used for self-locking. However, the reliability of this self-locking in the event of external mechanical shocks such as vibration It will decrease, and the nut and the bolt will become loose, so in some important occasions, some anti-loosening measures will be taken to ensure the reliability of the nut locking. The lock nut is one of the anti-loosening measures. The original lock nut The flat square structure is adopted, and the size of the flat square is relatively large. Every time it is adjusted, a large-scale pipe wrench is required for disassembly and assembly. The pipe wrench is relatively heavy. It is not convenient to disassemble the pliers

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

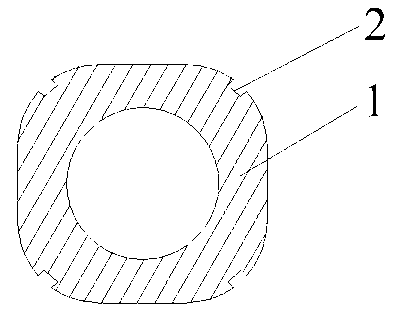

[0008] Such as figure 1 As shown, the present invention includes a nut body 1, the nut body 1 adopts a circular structure, and the outer circumference of the nut body 1 is provided with a rectangular notch 2; the rectangular notch 2 is provided with four; 2 Screwing can complete the disassembly and assembly of the nut body 1.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides a locking nut, which has the advantages of simple structure, convenience in adjustment and capability of greatly improving the reliability of a fastener. The locking nut comprises a nut body, wherein the nut body is in a circular structure; and four rectangular notches are arranged on the outer circumference of the nut body.

Description

technical field [0001] The invention relates to engineering nuts, in particular to locking nuts. Background technique [0002] In some equipment and facilities, it is often necessary to fasten the parts. Generally speaking, the friction between the nut and the bolt is used for self-locking. However, the reliability of this self-locking in the event of external mechanical shocks such as vibration It will decrease, and the nut and the bolt will become loose, so in some important occasions, some anti-loosening measures will be taken to ensure the reliability of the nut locking. The lock nut is one of the anti-loosening measures. The original lock nut The flat square structure is adopted, and the size of the flat square is relatively large. Every time it is adjusted, a large-scale pipe wrench is required for disassembly and assembly. The pipe wrench is relatively heavy. It is also inconvenient to disassemble and assemble the pliers. Contents of the invention [0003] In v...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F16B37/00

Inventor 黄漪

Owner WUXI YAQING MACHINERY

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com