High-strength three-dimensional support system of yielding type restriction concrete lagging jack

A technology of concrete arch frame and yielding type, which is applied in the field of deep underground roadway support system, can solve the problems that affect the production and safety of deep rock mass engineering, large deformation of deep soft rock caverns, and unsatisfactory effects, and achieve anti-corrosion The effect of strong deformation capacity, high support strength and high bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

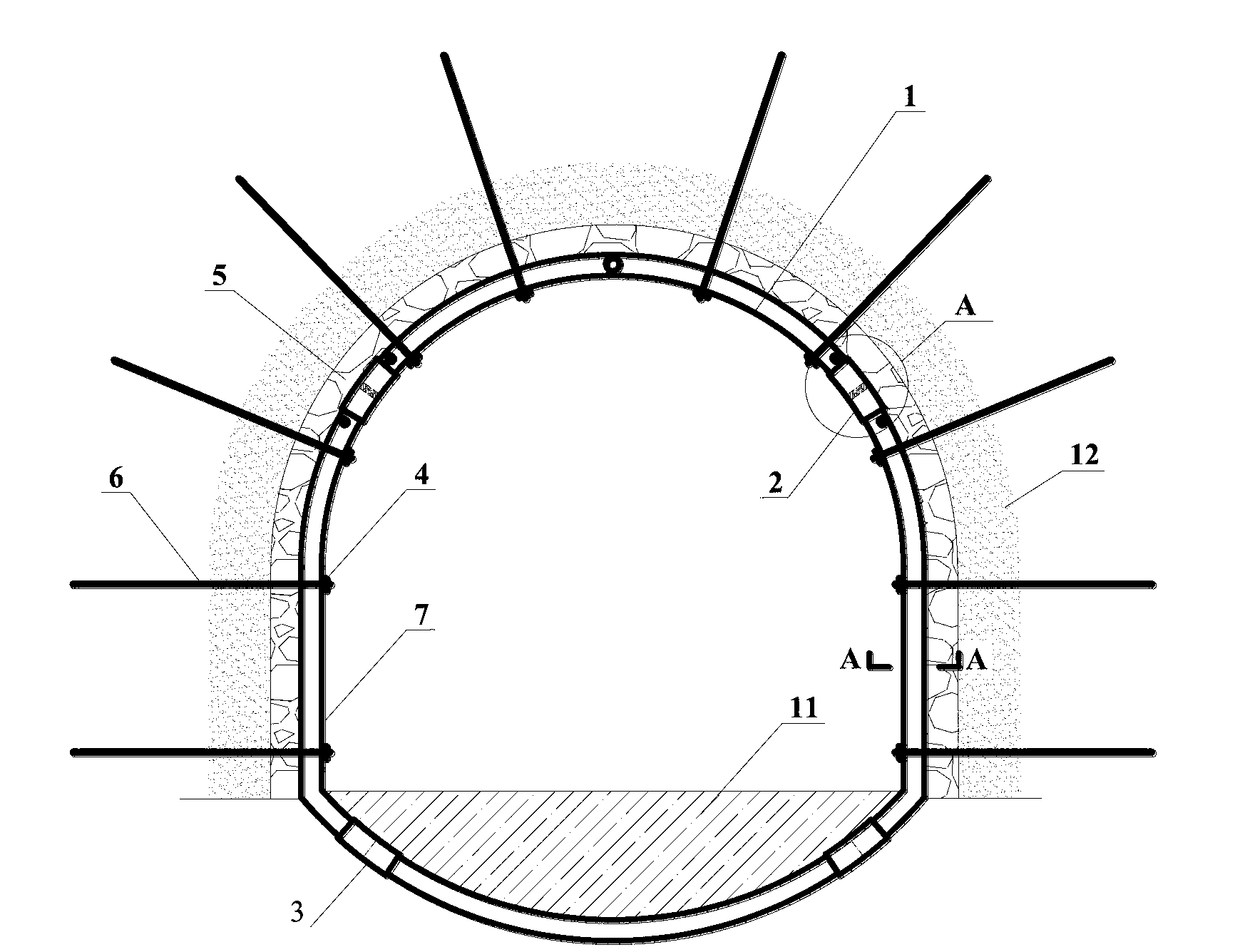

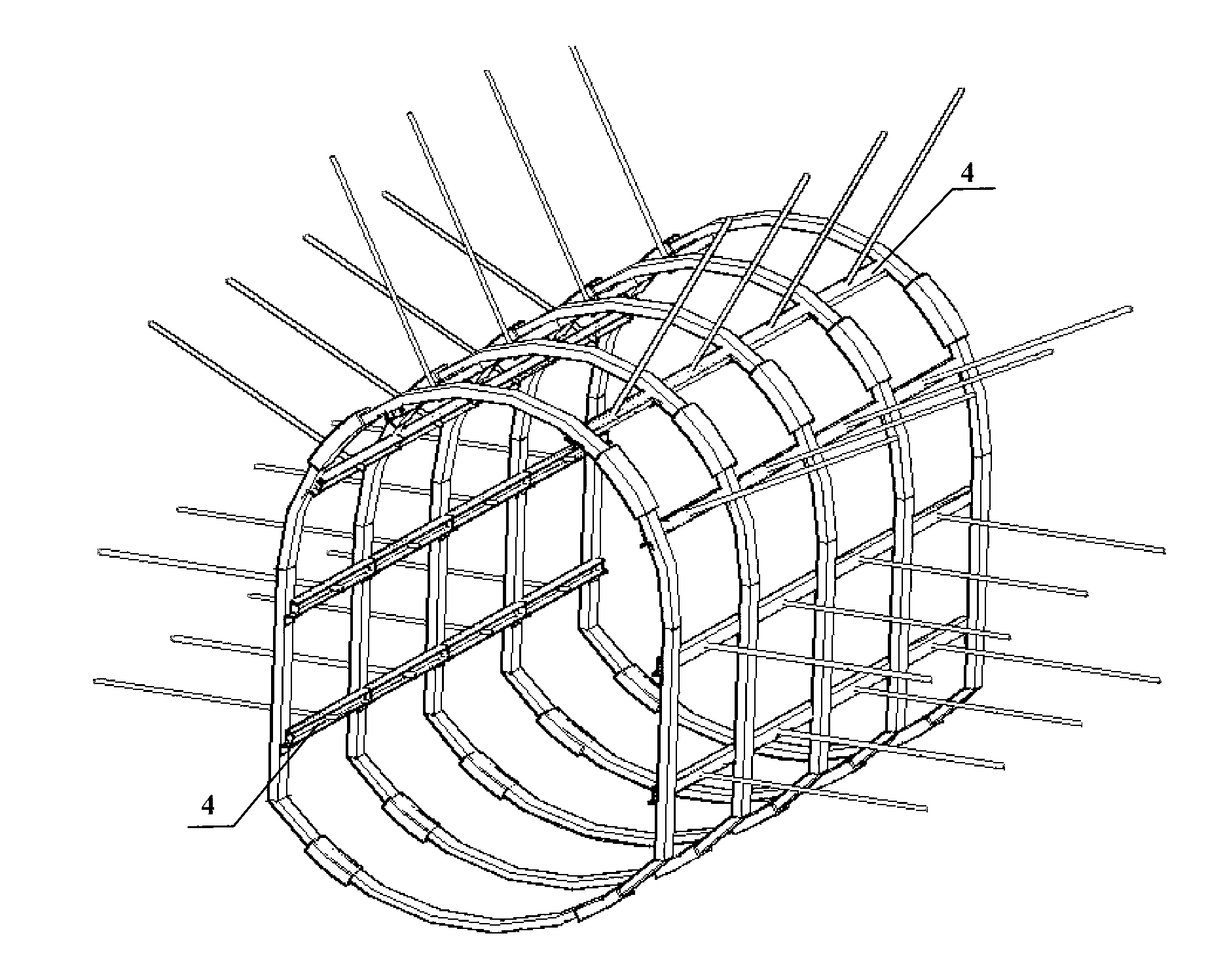

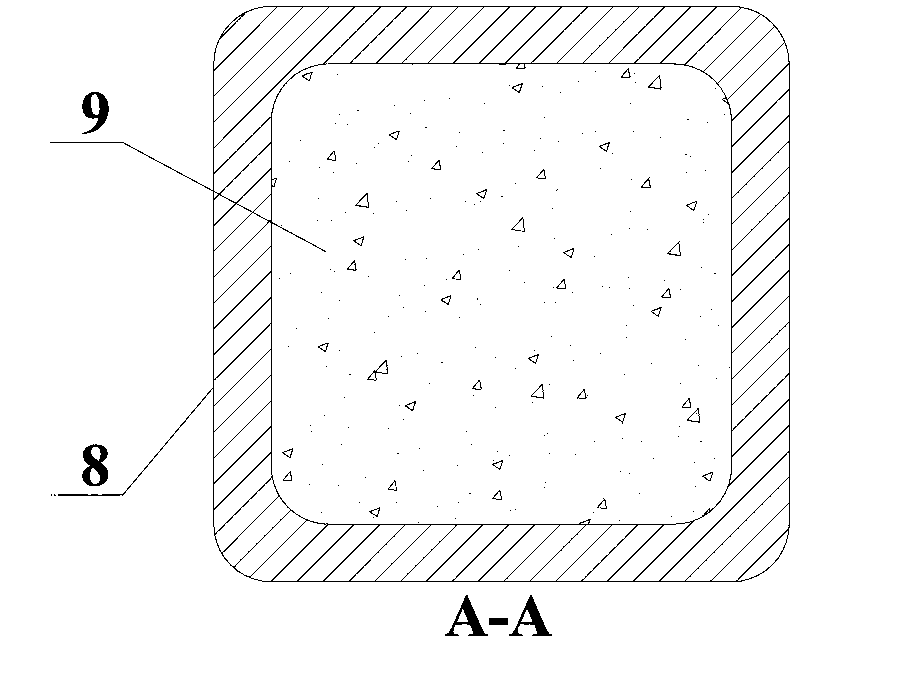

[0023] refer to Figure 1~2 , the specific embodiment of the present invention is that the high-strength three-dimensional support system of the pressure-constrained concrete arch is mainly composed of a constrained concrete arch 1, a pressure node 2, a longitudinal beam 4, and an anchor rod 6. The constrained concrete arch 1 is The closed straight wall arch and inverted bottom arch structure consistent with the shape of the roadway are arranged at a certain distance. 6 passes through the longitudinal beam 4 and then anchors into the surrounding rock 12, and applies prestress to form a squeezing effect on the surrounding rock 12. The anchor rod 6 forms a three-dimensional support system through the longitudinal beam 4 and the constrained concrete arch 1. A leveling and energy-releasing layer 5 is arranged between the constrained concrete arch 1 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com