Photochromic resin for chemical leather and preparation method of the photochromic resin

A technology of photosensitive discoloration and synthetic leather, which is applied in fiber treatment, textiles and papermaking, etc. It can solve the problems of poor comprehensive treatment effect, failure to meet environmental protection standards, and poor hand feeling of synthetic leather, achieving bright color, good comprehensive effect, and high production efficiency. The effect of the equipment increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The photochromic resin for synthetic leather consists of 10 parts by weight polyurethane resin, 15 parts by weight acrylic resin, 25 parts by weight butyl acetate, 25 parts by weight xylene, 3 parts by weight photochromic powder, 1 part by weight castor oil and 1 part by weight xylene Composition of base silicone oil.

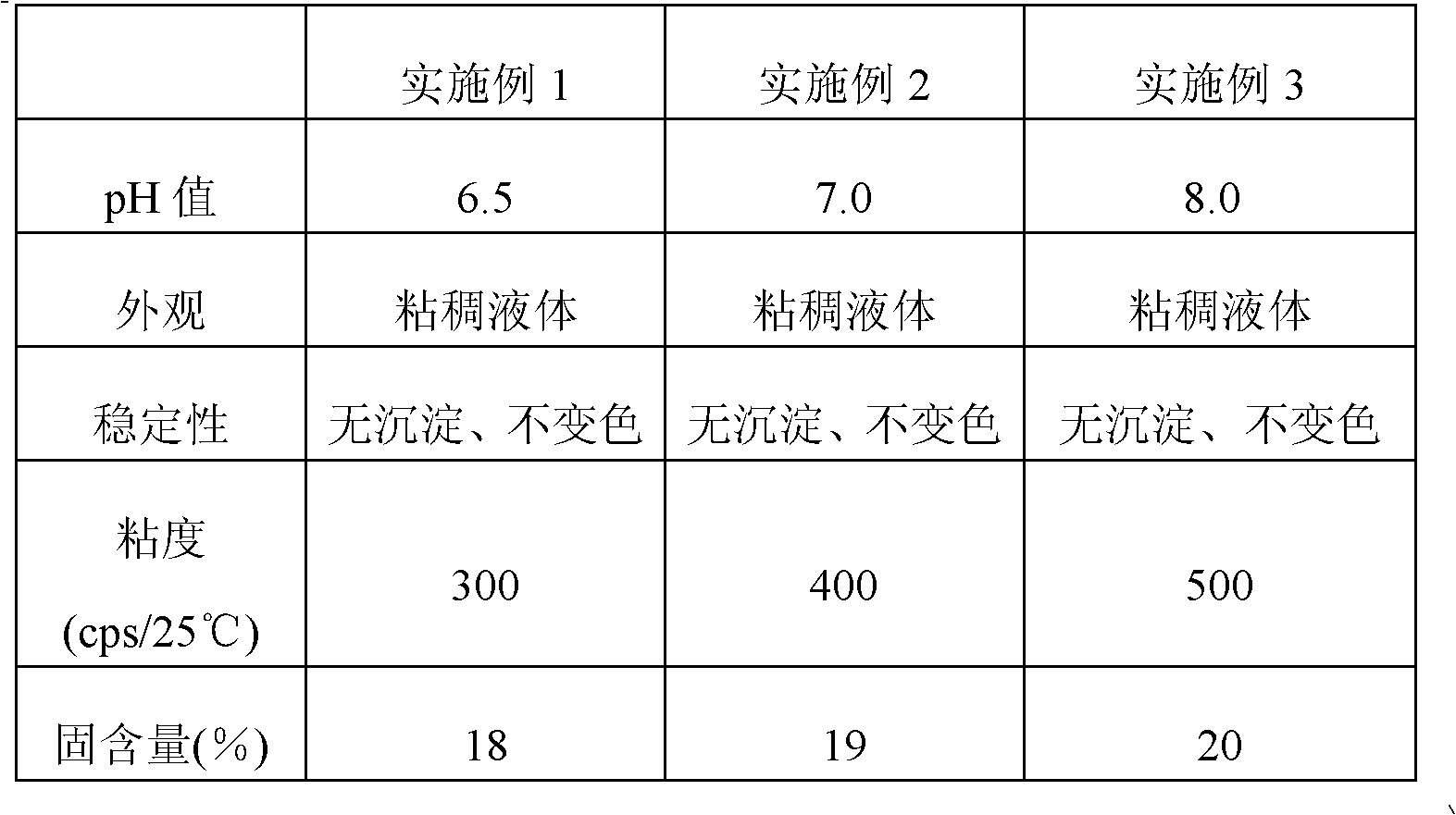

[0023] The preparation method of the above-mentioned photochromic resin for synthetic leather is: mix 10 parts by weight of polyurethane resin, 3 parts by weight of photochromic powder, 25 parts by weight of butyl acetate and 25 parts by weight of xylene, and stir evenly; add 15 parts by weight to the resulting mixture. The weight part of acrylic resin is stirred evenly; 1 weight part of simethicone and 1 weight part of castor oil are added to the obtained mixture, stirred evenly, and filtered to obtain the photochromic resin for synthetic leather of the present invention. The performance indexes of the obtained photochromic resin for synthetic leather a...

Embodiment 2

[0026] The preparation method of this embodiment is the same as that of Example 1. The performance indexes of the obtained photochromic resin for synthetic leather are shown in Table 1.

[0027] The ratio of each component of the photochromic resin for synthetic leather disclosed in this embodiment is as follows: 15 parts by weight of polyurethane resin, 20 parts by weight of acrylic resin, 30 parts by weight of butyl acetate, 30 parts by weight of xylene, photochromic powder 4 parts by weight, 1.5 parts by weight of castor oil and 1.5 parts by weight of simethicone oil.

Embodiment 3

[0029] The preparation method of this embodiment is the same as that of Example 1. The performance indexes of the obtained photochromic resin for synthetic leather are shown in Table 1.

[0030] The ratio of each component of the photochromic resin for synthetic leather disclosed in this embodiment is as follows: 20 parts by weight of polyurethane resin, 25 parts by weight of acrylic resin, 35 parts by weight of butyl acetate, 35 parts by weight of xylene, photochromic powder 5 parts by weight, 2 parts by weight of castor oil and 2 parts by weight of simethicone.

[0031] Table 1

[0032]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com