Preparation method for wood adhesive with starch as raw material

A technology of wood adhesives and raw materials, applied in the direction of starch adhesives, adhesive types, chitin adhesives, etc., can solve the problem of excessive use of organic solvents, inability to fully utilize resources, and non-approval of genetically modified foods, etc. problem, to achieve the effect of strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

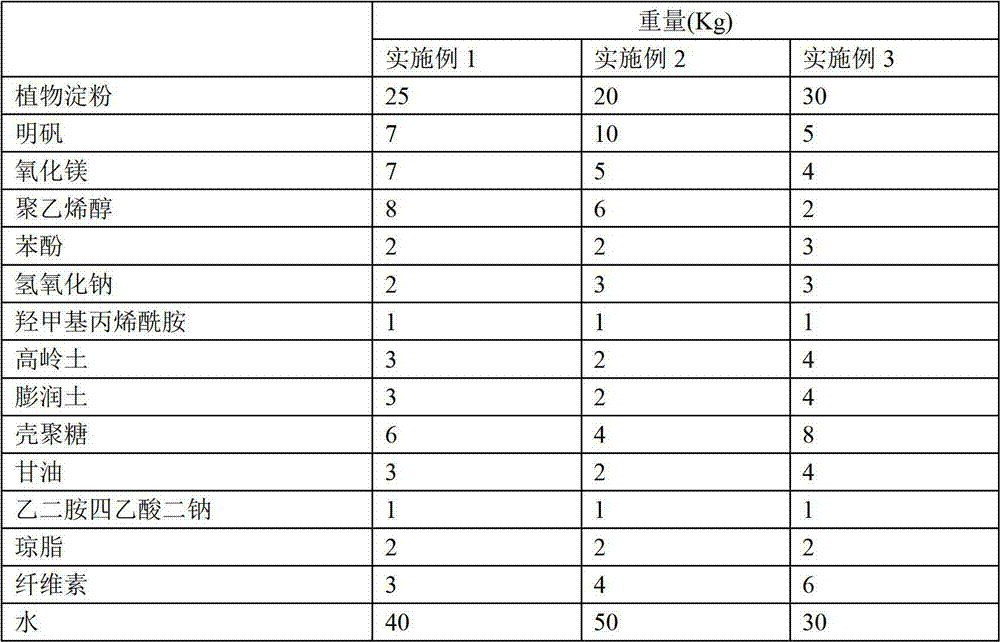

Embodiment 1

[0022] S1: Add water into the reaction window and raise the temperature to 30°C;

[0023] S2: Add vegetable starch, alum, magnesium oxide, polyvinyl alcohol, phenol, and sodium hydroxide under the condition of starting stirring, and react for 60 minutes at a reaction temperature of 30°C;

[0024] S3: Add methylolacrylamide, chitosan, glycerin, disodium edetate, agar, and cellulose, start stirring, the reaction temperature is 30°C, and the reaction time is 60 minutes;

[0025] S4: Cool down to 20°C, hold for 60 minutes;

[0026] S5: Heat up to 30°C, add kaolin and bentonite, and stir evenly.

Embodiment 2

[0028] The difference with Example 1 is: the temperature in S1 is 40°C; the reaction temperature in S2 is 40°C, and the reaction time is 120 minutes; the reaction temperature in S3 is 35°C, and the reaction time is 100 minutes; 25°C in S4, the holding time 100 minutes; temperature in S5 was 35°C.

Embodiment 3

[0030] The difference with Example 1 is: the temperature in S1 is 50°C; the reaction temperature in S2 is 50°C, and the reaction time is 240 minutes; the reaction temperature in S3 is 40°C, and the reaction time is 120 minutes; 30°C in S4, the holding time 120 minutes; temperature in S5 was 40°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com