Method for preparing graphene/metal phthalocyanine compound composite material through electrostatic assembly

A metal phthalocyanine and graphene technology, which is applied in the field of electrostatic assembly to prepare graphene/metal phthalocyanine compound composite materials, can solve the problems of easy agglomeration of graphene and uneven distribution of metal phthalocyanine, and can prevent self-agglomeration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

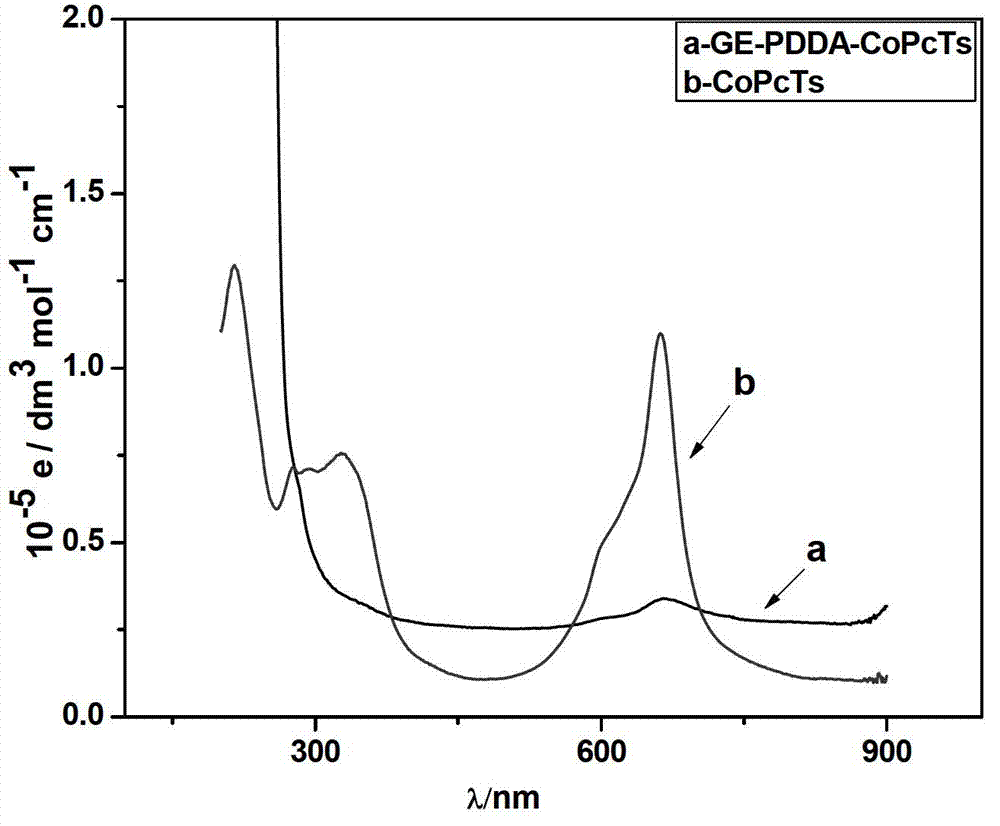

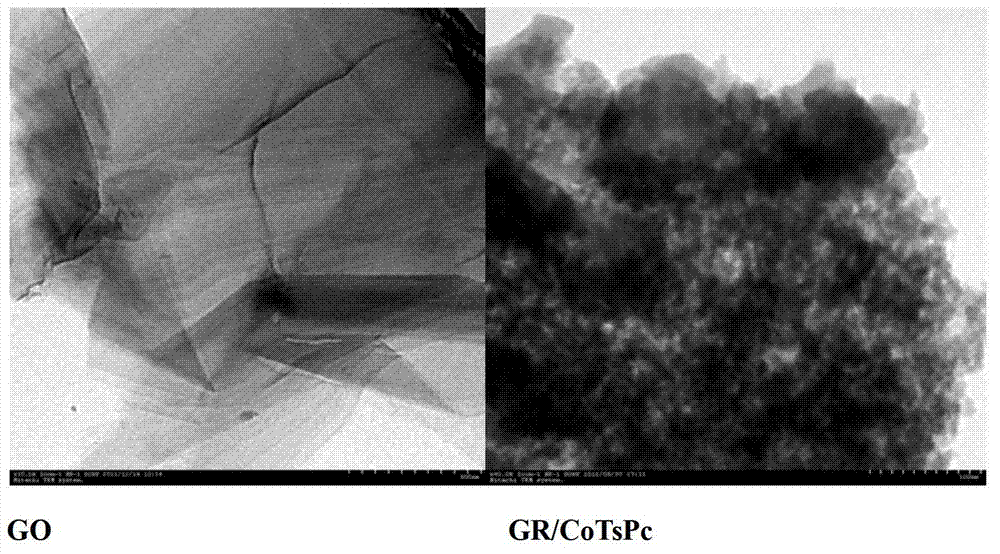

[0020] 20mL graphene oxide (GO) aqueous solution (1mg / mL), 10ml PDDA (dispersed in 0.5M NaCl solution, mass concentration 1%) NaCl solution, stirred overnight, the solution was brown, and the above Adjust the pH of the mixture to 10-12, add 8 μL of hydrazine hydrate (85%), continue to stir, and react in a water bath at 95°C for 24 hours. The product was centrifuged, washed with water, and vacuum-dried at 60°C for 24 hours to obtain black powder GR / PDDA. 20 mg of GR / PDDA was dispersed in 20 mL of deionized water, and sonicated for 1 hour. Continue to add 20 mg sulfonated cobalt phthalocyanine (CoTsPc), stir for 24 hours, centrifuge, wash with water, and vacuum dry at 60 °C for 24 hours to obtain a black powder GR / CoTsPc composite material.

Embodiment 2

[0022] 20mL graphene oxide (GO) aqueous solution (1mg / mL), 10ml PDDA (dispersed in 0.5M NaCl solution, mass concentration is 1%), stirred overnight, the solution was brown, and the above mixture was dissolved with NaOH (0.2M) Adjust the pH to 10-12, add 20mg NaBH4, continue to stir, and react in a water bath at 95°C for 24h. The product was centrifuged, washed with water, and vacuum-dried at 60°C for 24 hours to obtain black powder GR / PDDA. 20 mg of GR / PDDA was dispersed in 20 mL of deionized water, and sonicated for 1 hour. Add 20 mg sulfonated iron phthalocyanine (FeTsPc), stir for 24 hours, centrifuge, wash with water, and vacuum dry at 60°C for 24 hours to obtain black powder GR / FeTsPc composite material.

Embodiment 3

[0024] 10mL graphene oxide (GO) aqueous solution (1mg / mL), 5ml PDDA (dispersed in 0.5M NaCl solution, mass concentration 1%), stirred overnight, the solution was brown, and the above mixed solution was adjusted with ammonia water (28%) pH = 10-12, add 4 μL hydrazine hydrate (85%), continue to stir, and react in a water bath at 95°C for 24 hours. The product was centrifuged, washed with water, and dried under vacuum at 60°C for 24 hours to obtain a black powder of GR / PDDA. 10 mg of GR / PDDA was dispersed in 10 mL of deionized water and ultrasonicated for 1 hour. Add 10 mg tetracarboxy cobalt phthalocyanine (CoTcPc), stir for 24 hours, centrifuge, wash with water, and vacuum dry at 60°C for 24 hours to obtain a black powder GR / CoTcPc composite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com