Biological carbon organic fertilizer and preparation method thereof

A technology of biochar and organic fertilizer, applied in the direction of fertilization device, fertilizer mixture, application, etc., can solve the problems of ineffective comprehensive utilization technology, achieve the effect of enhancing yield and quality, improving fertilizer utilization rate, and improving absorption and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

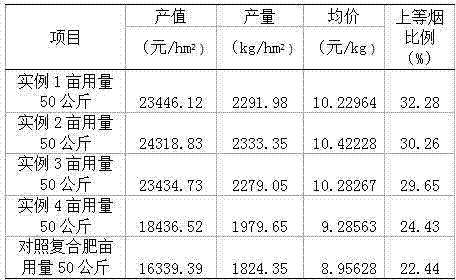

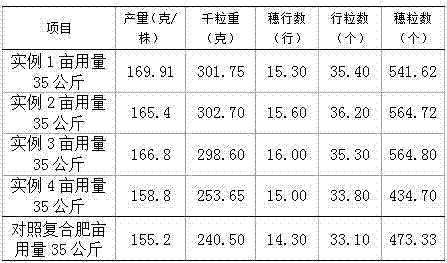

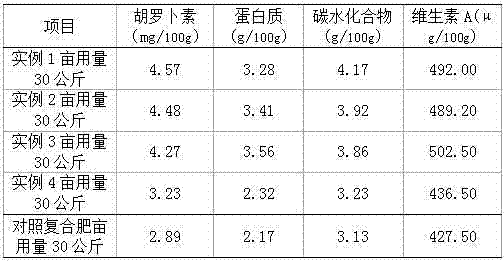

Examples

Embodiment 1

[0027] Put the flue-cured tobacco stalks into the vacuum carbonization kiln, heat up, carbonize and calcinate (carbonization temperature is 600°C, carbonization time is 5h, cool after calcining, and then dry and pulverize (particle diameter 0.5mm), so that the nutrients in it According to the mass ratio, N:P2O5:K2O=4:1:15, a total of 32.12kg, through the screw conveyor, together with the fermented organic matter (livestock manure or oil dryness) and trace elements are sent to the mixer in the negative pressure Blending at -45 kPa, where the organic matter fermentation uses a biological decomposing agent (HM decomposing agent produced by Henan Henglongtai Biological Engineering Co., Ltd.) for decomposing fermentation, the fermentation temperature is 70 ° C, the time is 4 days, and then dried Grinding (particle size 0.3mm), the nutrients in the organic matter, by mass ratio, N:P2O5:K2O=10:8:6, a total of 64.12kg added; trace elements are borax, magnesium sulfate, zinc sulfate and...

Embodiment 2

[0029] Put the flue-cured tobacco stalks into the vacuum carbonization kiln, heat up, carbonize and calcinate (carbonization temperature is 600°C, carbonization time is 5h, cool after calcining, and then dry and pulverize (particle size 0.8mm), so that the Nutrients are calculated by mass ratio, N:P2O5:K2O=5:2:16, a total of 34.60kg, through the screw conveyor, together with the fermented organic matter (livestock manure or oil dry) and trace elements are sent to the mixer under negative pressure Blending under the condition of (-48 kPa), in which, the organic matter fermentation uses biological decomposing agent (HM decomposing agent produced by Henan Henglongtai Biological Engineering Co., Ltd.) for decomposing fermentation, the fermentation temperature is 70 ℃, and the time is 4 days , and then dried and crushed (particle size 0.3mm), the nutrients in the organic matter, by mass ratio, N:P2O5:K2O=9:7:5, a total of 62.83kg added; trace elements are borax, magnesium sulfate, s...

Embodiment 3

[0031] Put the flue-cured tobacco straw into the vacuum carbonization kiln, heat up, carbonize and calcinate (carbonization temperature is 600°C, carbonization time is 5h, cool after calcining, and then dry and pulverize (particle size 0.6mm), so that the Nutrients are calculated by mass ratio, N:P2O5:K2O=4.5:1.5:15.5, a total of 33.46kg, through the screw conveyor, together with the fermented organic matter (livestock manure or oil dry) and trace elements are sent to the mixer negative pressure ( Blending under the condition of -50 kPa), in which, the organic matter fermentation uses biological decomposing agent (HM decomposing agent produced by Henan Henglongtai Biological Engineering Co., Ltd.) for decomposing fermentation, the fermentation temperature is 70 ° C, and the time is 4 days , and then dried and crushed (particle size 0.3mm), the nutrients in the organic matter, by mass ratio, N:P2O5:K2O=9.5:7.5:5.5, a total of 63.41kg added; trace elements are borax, magnesium sulf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com