A large-size solid optical fiber preform and its preparation method and equipment

An optical fiber preform and preform technology, which is applied in the field of optical fiber processing, can solve the problems of high cleanliness and operational details, the process is easily affected by operation, increased processing costs and processing risks, etc., to achieve easy control and adjustment , large size, size range and the effect of increased wire drawing length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

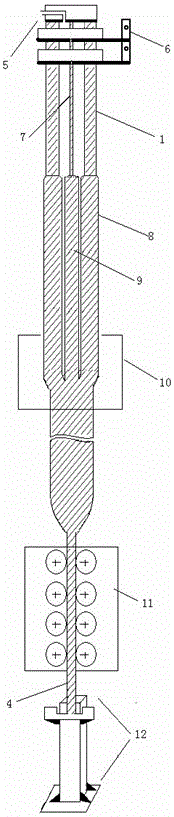

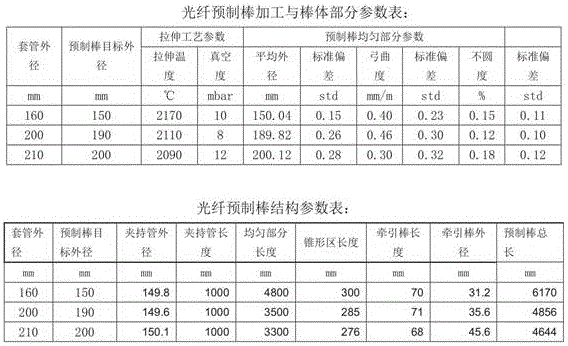

[0032] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0033] The preparation process is as follows: select a pure silica glass sleeve 8 and an optical fiber core rod 9 with matching parameters, make the aperture and length of the pure silica glass sleeve match the outer diameter and length of the optical fiber core rod, and pre-process the pure silica glass sleeve. For processing, a glass clamping tube 1 with a smaller diameter is welded on the upper end of the pure quartz glass sleeve as the clamping end, and a section of ordinary glass rod is welded on the lower end of the pure quartz glass sleeve. Extension rod 7; clean and dry the pure silica glass sleeve and optical fiber core rod; combine the cleaned and dried pure silica glass sleeve and optical fiber core rod to form a combined rod, vertically install it on the preform rod melting and shrinking equipment, and assemble the rod The clamping end is cla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com