Oil-water automatic control separation device

A technology for separation equipment and oil-water separation, which is applied in the fields of oil-water automatic control separation equipment, oil-water separation equipment, and petroleum purification equipment. It can solve problems such as waste of resources, pollution of the environment, and large waste of oil resources, and achieve the effect of avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

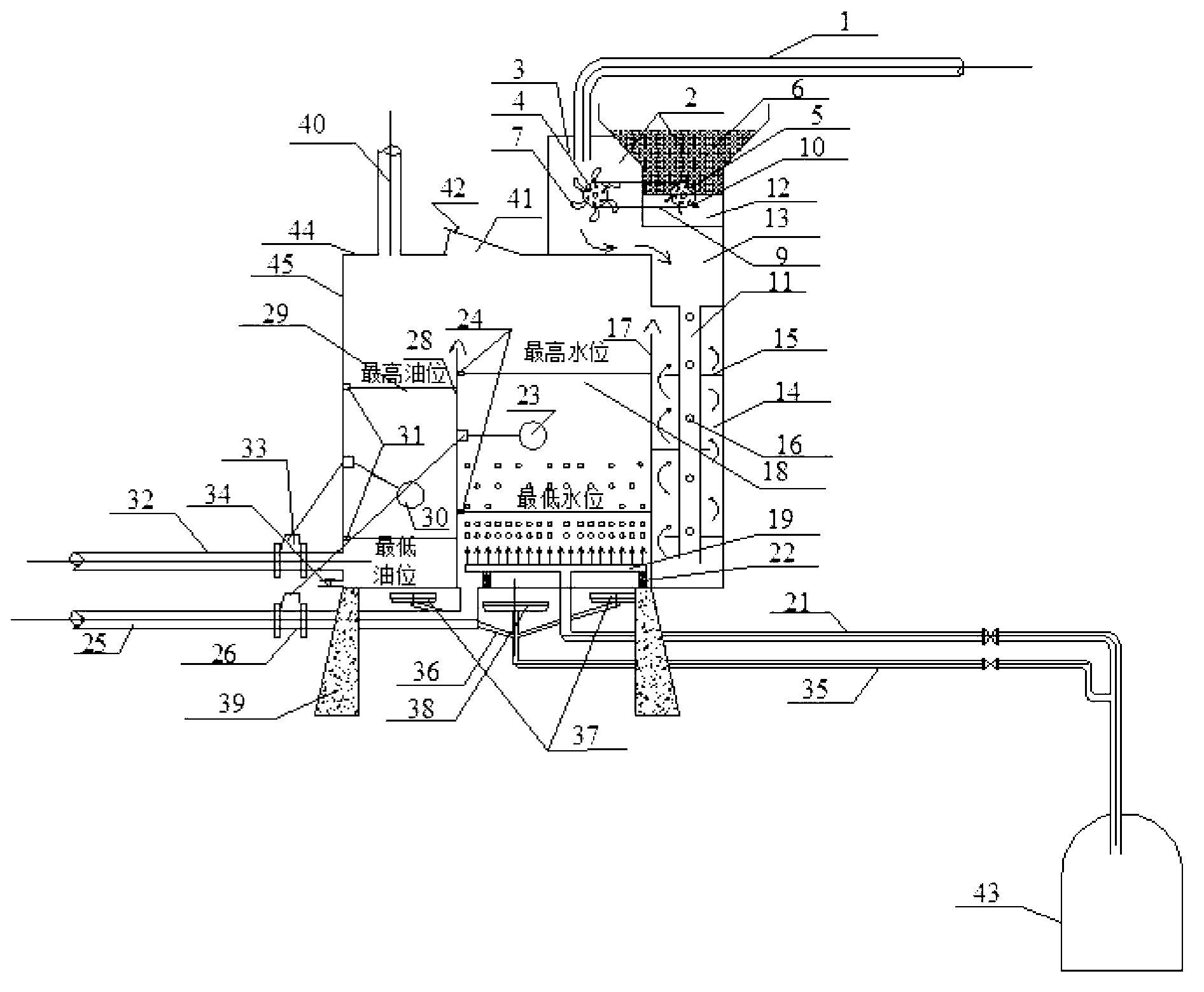

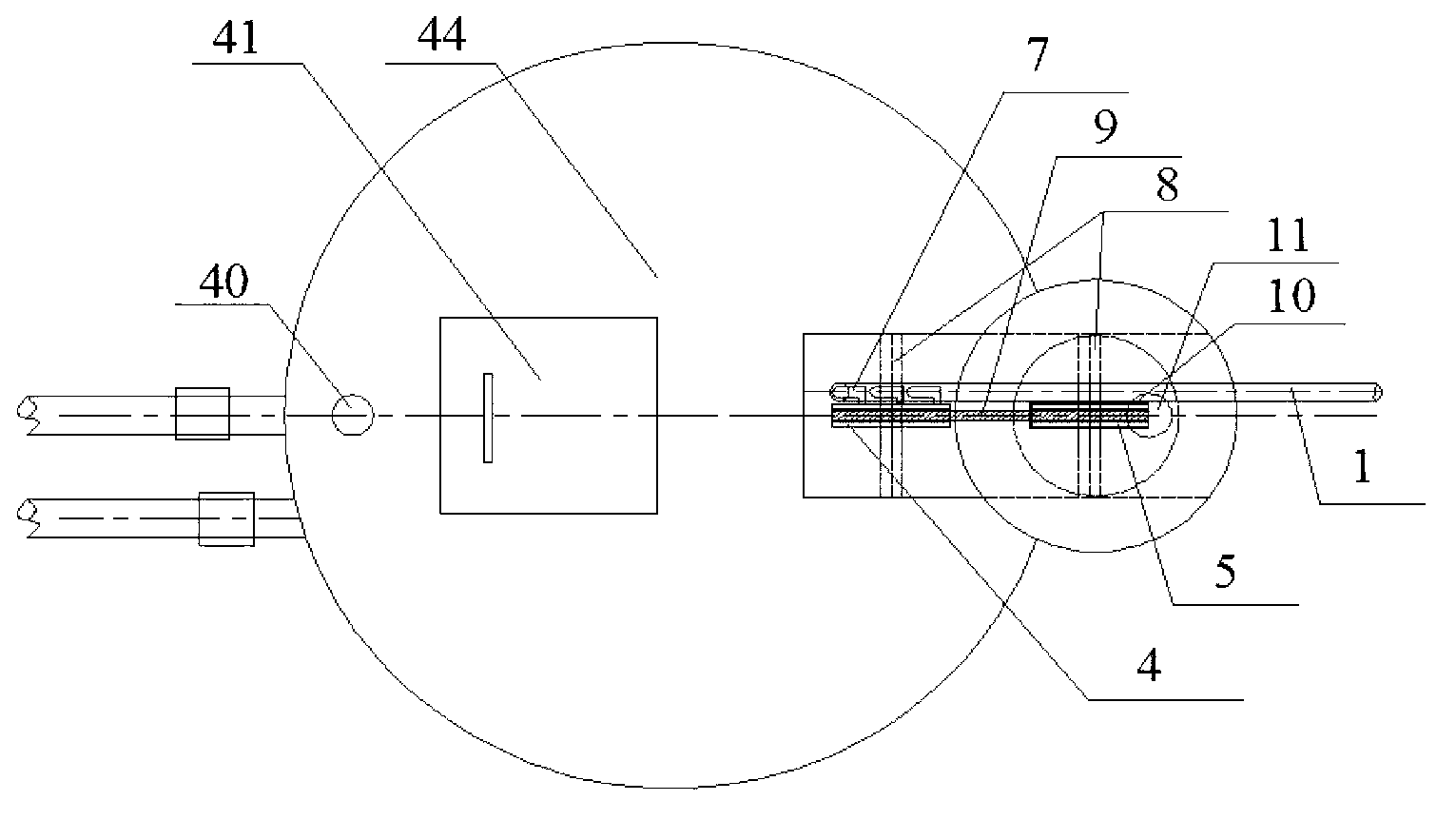

[0048] The main design concept of the oil-water automatic control equipment of the present invention is to organically combine the oil-water separation theory, uniform gas distribution theory, automatic control theory, mixing and energy dissipation theory, etc., and use the natural gas produced in the oil well exploitation process to make it fully utilized , and at the same time combine with the action of drugs to carry out efficient oil-water separation, and finally achieve the purpose of energy saving and emission reduction.

[0049] According to the theory of mutual incompatibility of oil and water under certain conditions, through the characteristics of air flotation and the basic properties of the added medicine, the oil and water can be separated efficiently, and then the separated oil and water will be discharged out of the equipment according to the automatic control system, so as to realize the maintenance of the equipment. cycle. The equipment has simple structure, c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com