Nonalcoholic carbonated beverage with typical beer flavor and production method thereof

A technology of carbonated beverages and beer flavors, applied in food science and other fields, can solve the problems of drivers' distraction, decreased tactile ability, and decreased response ability, and achieve the effects of increasing nutritional value, improving bubble retention, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Preparation of raw material syrup: Based on the total mass of non-alcoholic carbonated beverages, dissolve 0.15% soybean polysaccharide, 3.5% sucrose, and 2.0% fructose syrup (FE42 type) in water, stir evenly, and heat to 90°C for 30s to sterilize , cooled to 25°C and filtered to obtain a clear filtrate.

[0027] (2) Adding auxiliary materials: Add 0.015% potassium sorbate, acidity agent (sodium citrate: citric acid: lactic acid = 1:2:1), 0.03% beer essence, and 0.08% beer pigment to the syrup filtrate. The material is mixed evenly.

[0028] (3) Canned carbonated water: Tap water is purified by membrane filtration, sterilized by ultraviolet rays, cooled and carbonated. When canning, the prepared slurry is cooled to within 7°C and filled into carbonated water, the carbon dioxide gas content reaches 0.30%, and a carbonated beverage (1# sample) with a typical beer flavor is obtained.

Embodiment 2

[0030] (1) Preparation of raw material syrup: Based on the total mass of non-alcoholic carbonated beverages, dissolve 1.5% soybean polypeptide, 3.5% sucrose, and 2.0% fructose syrup (FE42 type) in water, stir evenly, and heat to 90°C for 30 seconds to sterilize , cooled to 25°C and filtered to obtain a clear filtrate.

[0031] (2) Adding auxiliary materials: Add 0.015% potassium sorbate, acidity agent (sodium citrate: citric acid: lactic acid = 1:1:2), 0.03% beer essence, and 0.08% beer pigment to the syrup filtrate. The material is mixed evenly.

[0032] (3) Canned carbonated water: Tap water is purified by membrane filtration, sterilized by ultraviolet rays, cooled and carbonated. When canning, the prepared slurry is cooled to within 7°C and filled into carbonated water, and the carbon dioxide gas content reaches 0.30%, and a carbonated beverage (2# sample) with a typical beer flavor is obtained.

Embodiment 3

[0034] (1) Preparation of raw material syrup: Based on the total mass of non-alcoholic carbonated beverages, dissolve 0.15% soybean polysaccharide, 1.5% soybean polypeptide, 3.5% sucrose, and 2.0% fructose syrup (FE42 type) in water, stir evenly, and heat Sterilize at 90°C for 30s, cool to 25°C and filter to obtain a clear filtrate.

[0035] (2) Add auxiliary materials: add 0.015% potassium sorbate, acidity agent (sodium citrate: citric acid: lactic acid mixed in a certain proportion), 0.03% beer essence, and 0.08% beer pigment to the syrup filtrate, and mix various materials uniform.

[0036] (3) Canned carbonated water: Tap water is purified by membrane filtration, sterilized by ultraviolet rays, cooled and carbonated. When canning, the prepared slurry is cooled to less than 7°C and filled with carbonated water, the carbon dioxide gas content reaches 0.30%, and a carbonated beverage (3# sample) with a typical beer flavor is obtained.

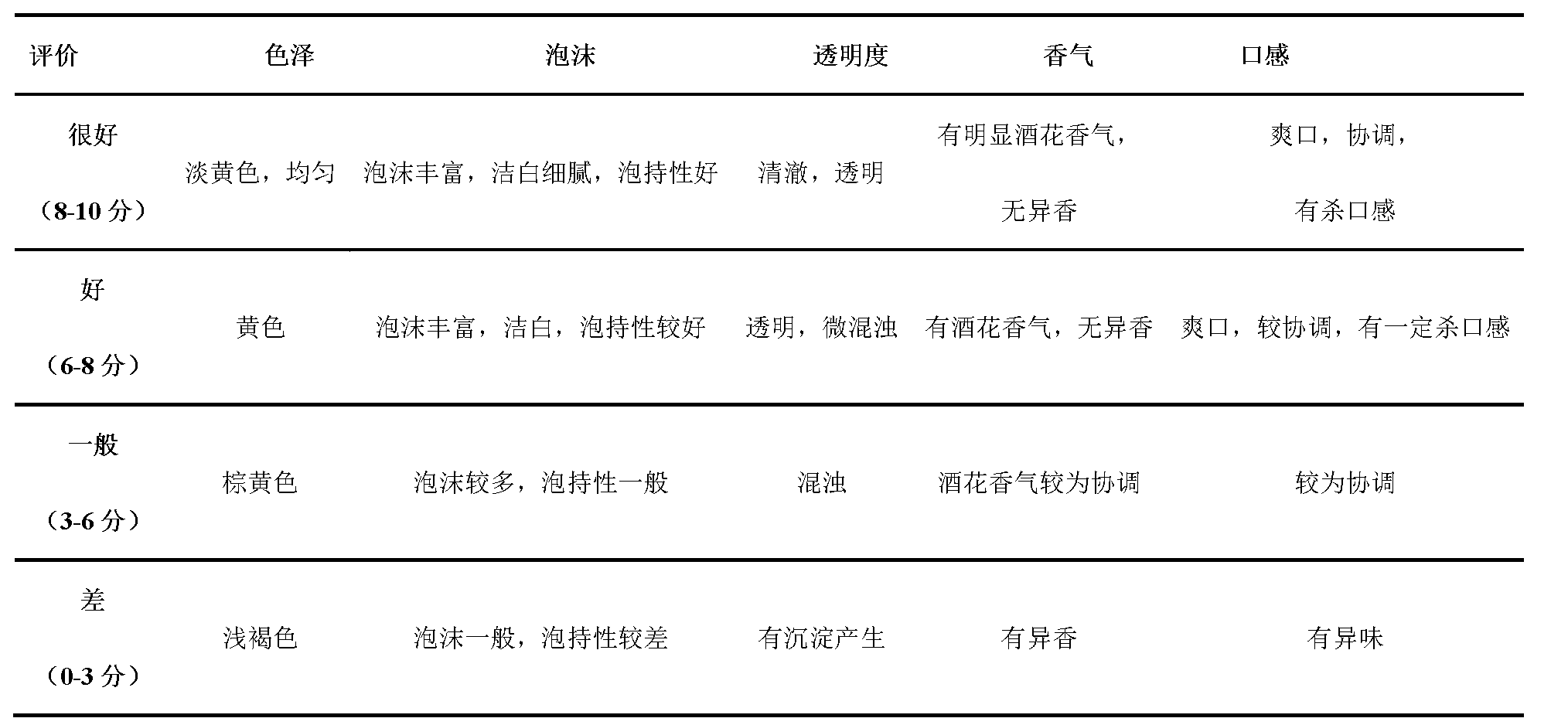

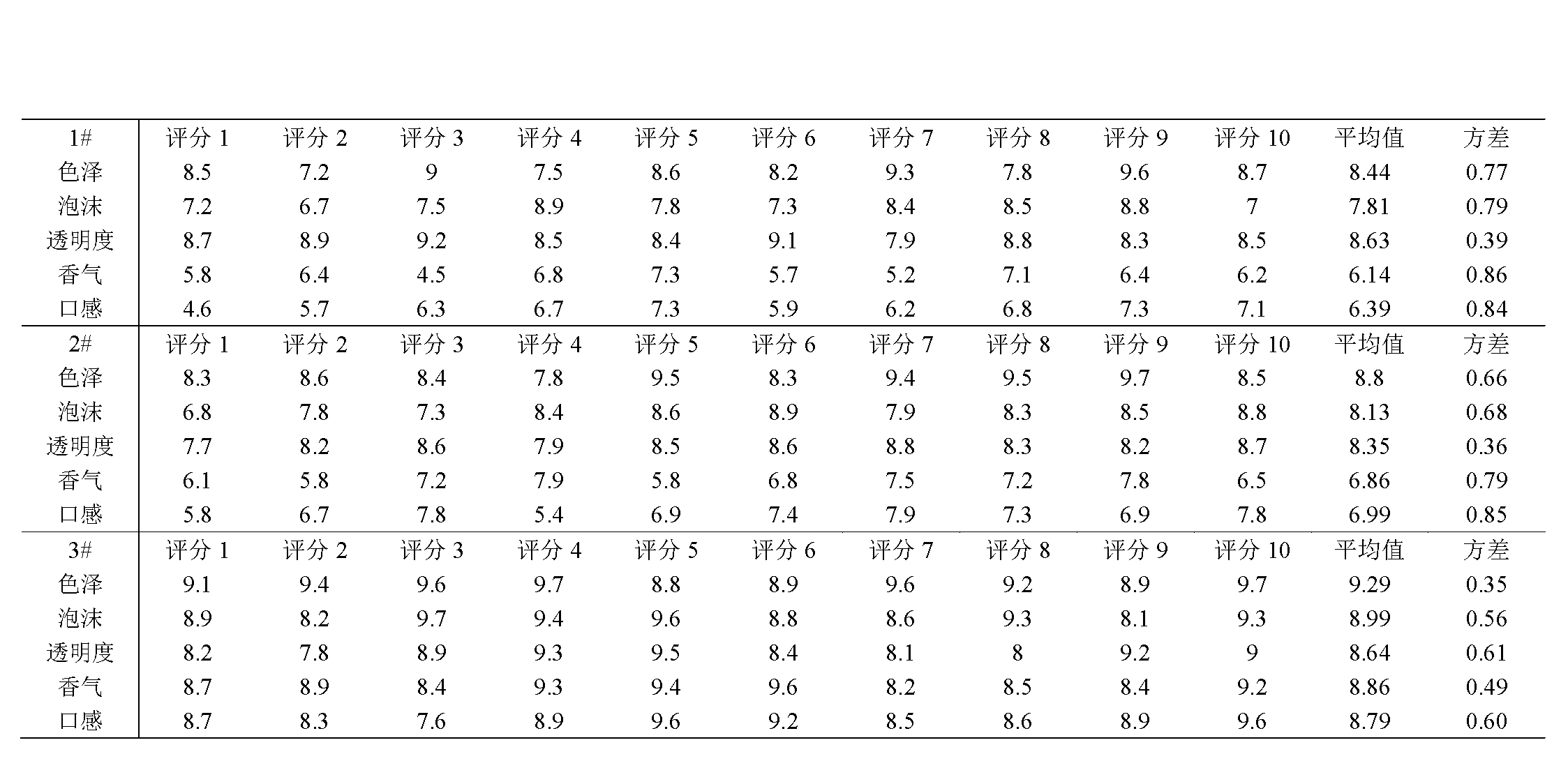

[0037] The 1#, 2# and 3# samples in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com