Vibration nipper for heavy machinery

A technology for heavy equipment and vibrating tongs, which is applied in mechanically driven excavators/dredgers, earthmoving machines/shovels, construction, etc., and can solve the problems of obstructing longitudinal vibration, easy damage and tearing of the vibrating tongs 1 , to achieve the effect of improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Hereinafter, exemplary embodiments of the present invention will be described in detail. Wherein, the same reference numerals denote the same elements.

[0032] The vibratory tongs 100 according to an embodiment of the present invention are installed on the arms of heavy equipment such as excavators, bulldozers, and loaders to simultaneously perform crushing and excavation work in civil engineering and demolishing fields.

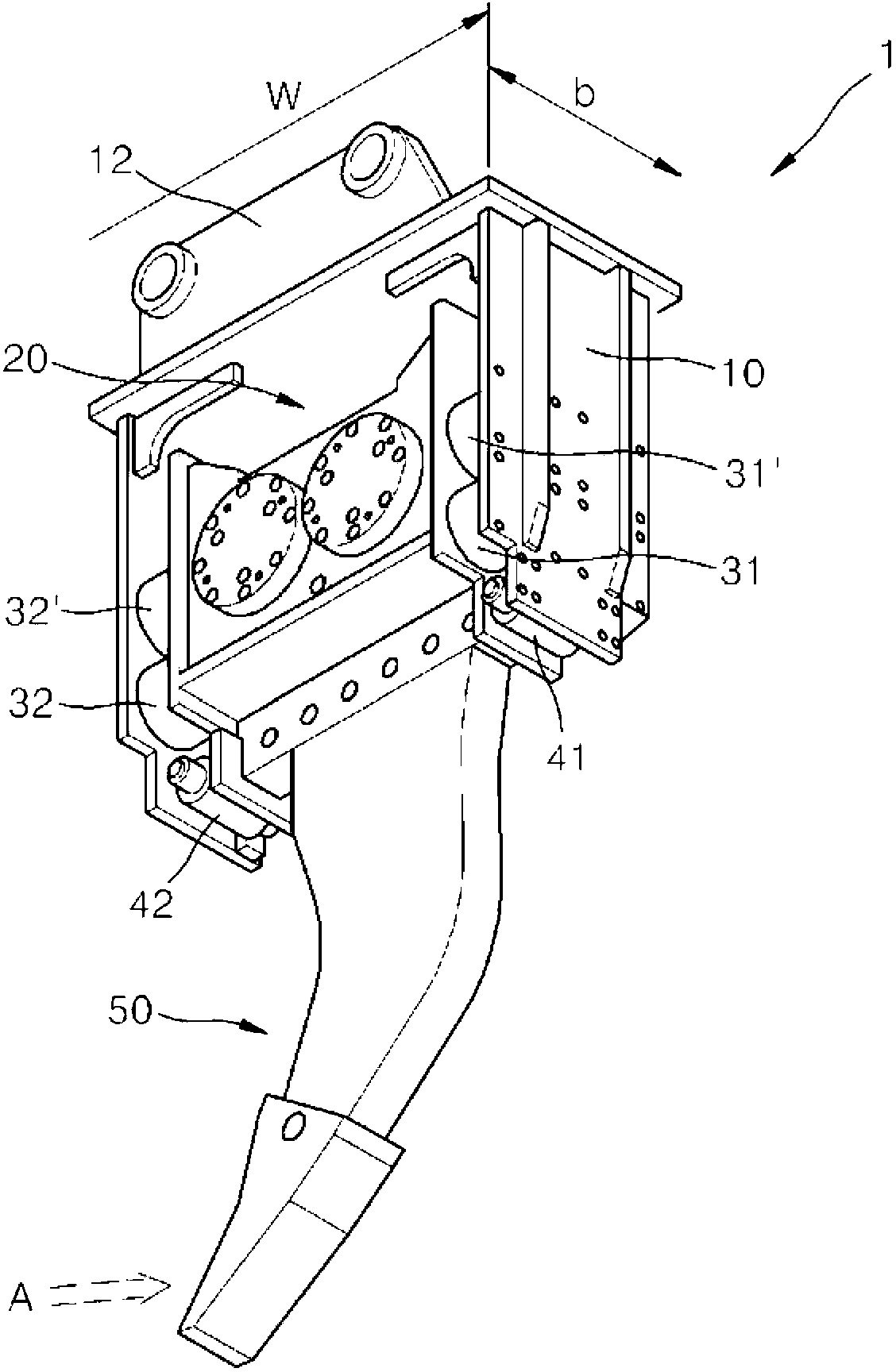

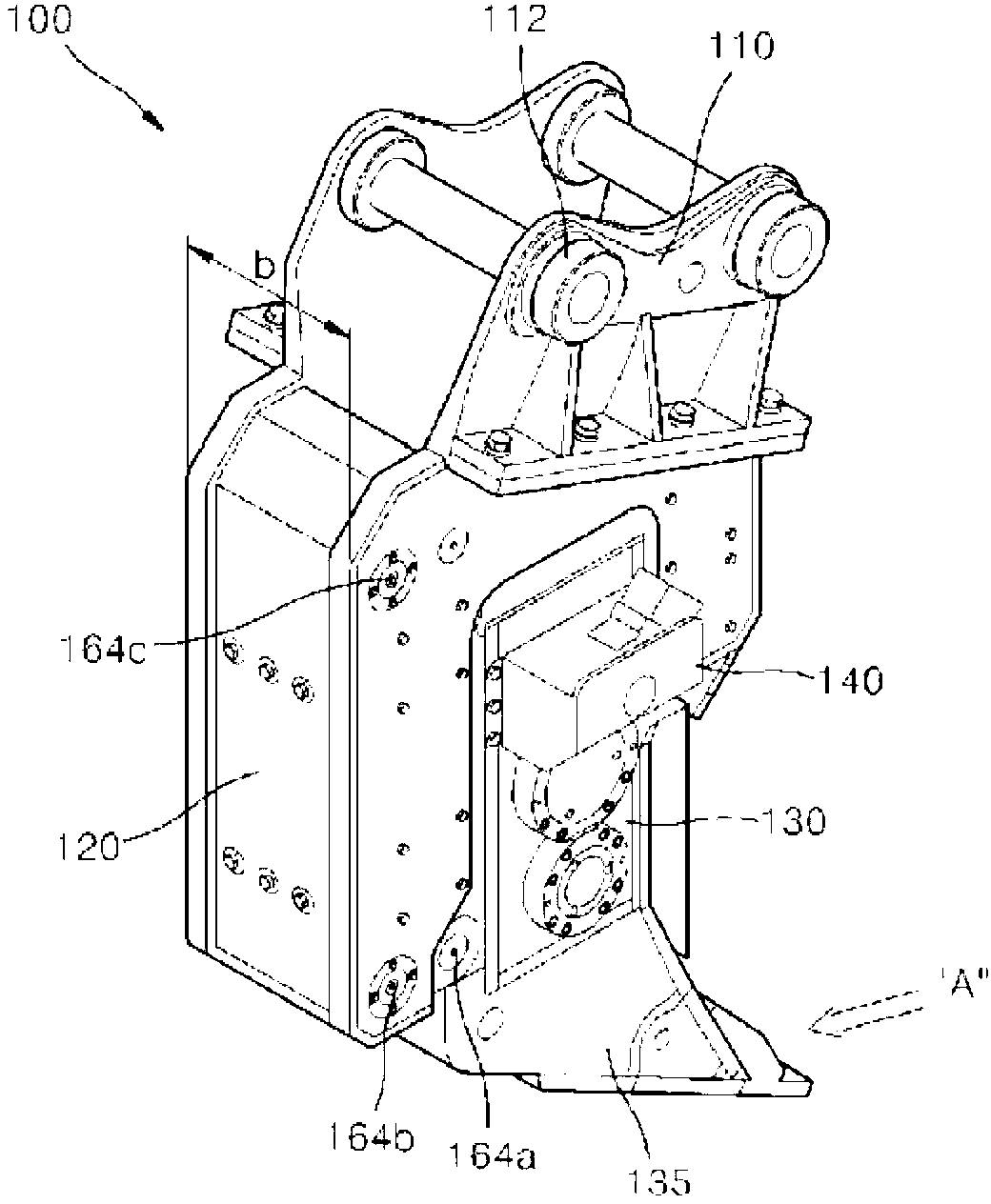

[0033] as in image 3As fully shown in , the vibrating tongs 100 have the structure of: a mounting part 110 formed on the top of the vibrating tongs 100, the mounting part 110 has an arm fixing hole 112 connected to an arm of a heavy equipment, and a frame 120 is approximately in the shape of a ∩ The ground is connected to the bottom of the installation part 110 , the vibrating body 130 is located inside the frame 120 , and the jaws 135 are mounted on the bottom of the vibrating body 130 .

[0034] Such as Figure 4 , Figure 5 and Figure 6 As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com